Many new all-grain brewers—and even some experienced ones—often ask whether it’s possible to shorten their brew day by reducing boil time. Since boiling does sterilize wort, the question usually sounds like this:

“If sterilization is the goal, can I just boil for 20–30 minutes instead of the full 60 or 90 minutes?”

The short answer:

You can shorten the boil in certain cases, but you may not get the beer you intended.

That’s because the boil stage does far more than simply kill microbes. It is one of the most critical phases in the entire brewing process. Understanding its functions will help you decide whether cutting the boil makes sense for a particular recipe—or if maintaining the traditional boil is essential.

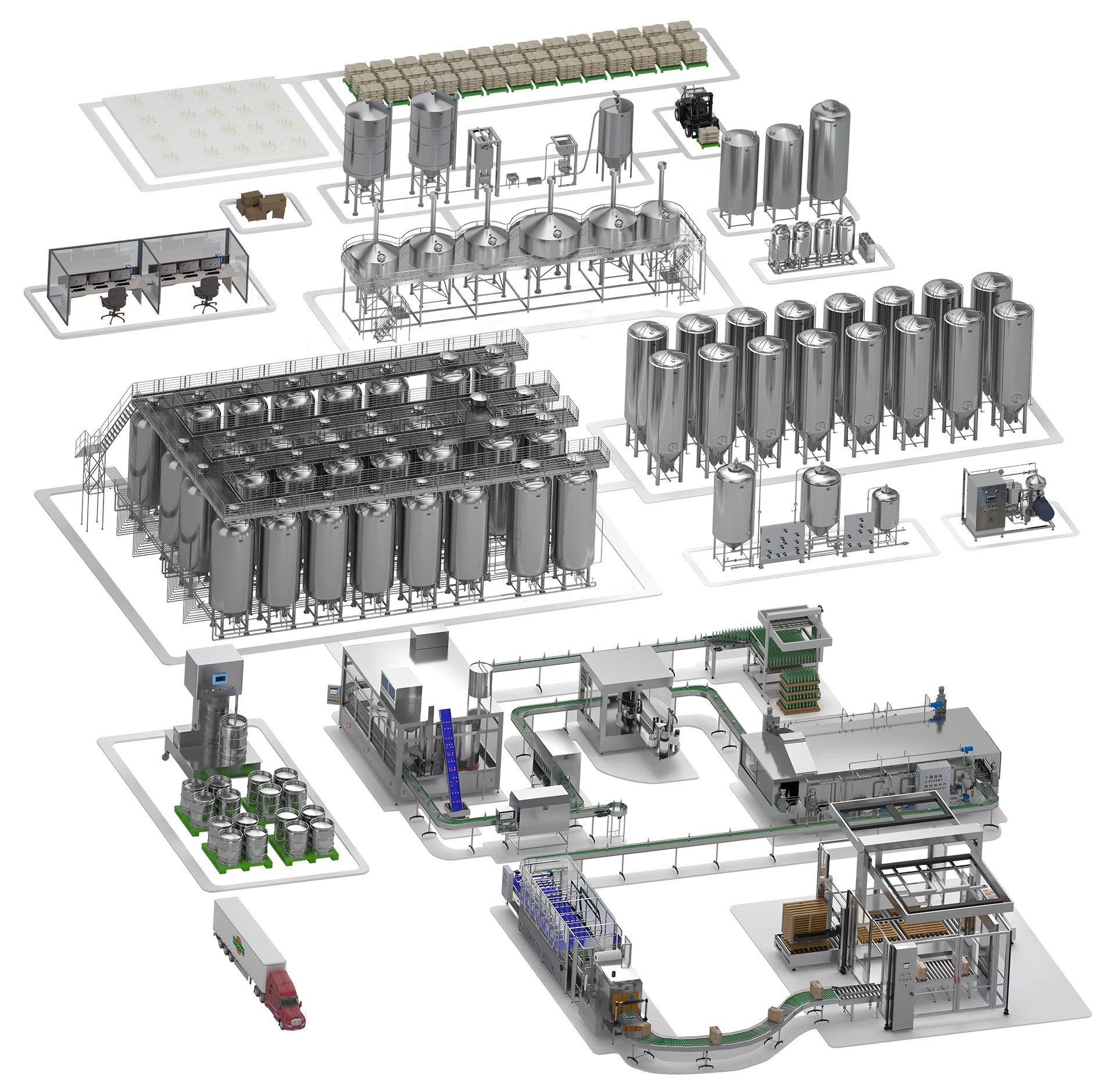

This article explains the many roles of wort boiling, why each is important, and how TIANTAI’s brewhouse design helps you achieve ideal boil performance, efficiency, and flavor quality. Whether you’re experimenting at home or brewing on a professional scale, this guide will help you brew better beer.

What Is Wort Boiling and Why Do We Do It?

After the mash and lautering stages, brewers collect sweet wort in the kettle. This wort must be boiled before it is ready for fermentation. Although sterilization is indeed one of its functions, boiling plays a much larger role in beer production.

A proper boil:

- Stops enzymatic activity

- Concentrates wort to achieve target gravity

- Isomerizes hop alpha acids (creating bitterness)

- Enhances color through chemical reactions

- Reduces wort pH

- Drives off volatile compounds like DMS

- Promotes protein coagulation (hot break)

- Improves clarity and stability

- Helps form the correct environment for yeast health

- Enhances aroma and flavor through hop additions

These functions all require time—and the right intensity of the boil—to happen correctly.

1. Stopping Enzyme Activity: The Boil “Locks In” Your Wort Profile

During mashing, enzymes like beta-amylase, alpha-amylase, proteases, and glucanases work together to convert grain starches into fermentable sugars. But once the mash is complete, you want these enzymes to stop working.

Why stop enzyme activity?

If enzymes continue reacting:

- Your wort could become too fermentable

- Beer may finish too dry

- Body and sweetness may disappear

- The intended beer style could be lost

Most enzymes become denatured between 50–75°C, which is the reason for performing a mash-out step at around 75°C for 10 minutes. This halts enzymatic action and prepares the mash for lautering.

But the boil ensures complete enzyme denaturation.

At 100°C, no enzymatic activity remains, meaning the wort now has a stable fermentability level that will not change unexpectedly.

TIANTAI mash tuns and kettle tuns include precise heating controls, insulation, and uniform temperature distribution to ensure mash-out and boiling are performed reliably, protecting the intended wort profile.

2. Concentrating the Wort: Achieving Target Gravity

Boiling wort removes water as steam, thereby increasing the concentration of sugars. The longer and stronger the boil, the more concentrated the wort becomes.

This is crucial because:

- It affects original gravity (OG)

- Higher OG increases alcohol potential

- Gravity also impacts mouthfeel and body

Brewers must know their evaporation rate. (For example, many systems evaporate around 2.5 L per hour.)

Gravity Calculation Example

Using the formula:

pre-boil volume × pre-boil gravity = post-boil volume × post-boil gravity

Let’s say:

Pre-boil volume = 28 L

Pre-boil gravity = 1.050 (use 50 points)

Evaporation = 2.5 L per hour

Post-boil volume = 25.5 L

Now calculate:

28 × 50 = 25.5 × post-boil gravity

1400 ÷ 25.5 = 54.9 points

So the final gravity ≈ 1.055

This shows how evaporation affects wort density. Reducing boil time would lower evaporation, meaning your OG would drop—unless you adjust water or malt accordingly.

TIANTAI boiling kettles include:

High-efficiency steam jackets

Optional external boiling systems

Precision evaporation rate control

Vent and condensation systems

These ensure predictable gravity results from batch to batch.

3. Isomerization of Alpha Acids: Creating Bitterness

Hops contain alpha acids, which are not soluble in wort in their natural form. They must undergo isomerization, a chemical reaction that occurs only at boiling temperatures.

Key points about hop isomerization:

- Most isomerization happens within the first 30 minutes

- Roughly 90% of the bitterness potential is achieved by 30 minutes

- Maximum efficiency is reached around 60–70 minutes

- Boiling longer does not significantly increase bitterness

- A shorter boil can be used, but you must adjust hop utilization

So while a 30-minute boil is possible, keep in mind:

- Gravity will be lower

- Color will be lighter

- DMS reduction may be insufficient

- Aroma hop timing will change

TIANTAI kettle Tuns are designed with smooth heat movement and efficient mixing to ensure consistent hop extraction and predictable bitterness.

4.Increasing Wort Color: Chemical Reactions During Boil

Boiling wort causes several reactions that deepen color and enrich flavor:

a) Maillard Reactions

These reactions between amino acids and reducing sugars produce:

Golden or amber coloration

Caramel/toffee notes

Depth and complexity

b) Caramelization

Occurs when sugars are heated and darken:

Gives richness

Enhances malt character

Helps develop certain beer styles (bocks, stouts, strong ales)

c) Polyphenol Oxidation

Oxidation of tannins forms compounds that:

Slightly darken color

Contribute to flavor development

These reactions require time and adequate heat. Cutting the boil can lead to:

Paler wort

Weaker malt flavor

Less complexity

TIANTAI’s kettles feature optimized steam jackets and heating surfaces to give strong, even boiling for reliable color development.

5. Reduction of Wort pH: Improving Clarity, Flavor, and Yeast Health

Wort pH changes during each stage of brewing. A proper boil helps achieve ideal pH conditions for fermentation.

Typical pH targets:

Mash pH: 5.2–5.5

Pre-boil pH: 5.2–5.4

Post-boil pH: drops by ~0.1–0.2 (ideal 5.0–5.3)

Finished beer pH: 4.2–4.6

Why does pH drop during boiling?

Because calcium forms insoluble salts that precipitate out. This lower pH:

Improves hot break formation

Enhances wort clarity

Increases long-term stability

Encourages healthy yeast growth

Reduces bacterial contamination risks

Skipping or shortening the boil means losing these pH benefits.

6. Driving Off Volatile Compounds: Removing DMS and Other Off-Flavors

One of the most important functions of boiling is removing dimethyl sulfide (DMS), a compound that creates “sweet corn” or “cooked vegetable” flavors.

Where does DMS come from?

DMS forms from SMM (S-methylmethionine), naturally found in malt—especially pilsner malts.

How do we remove it?

A strong, rolling boil volatilizes DMS

Steam removes DMS from the kettle

Maintaining an open, vented boil is critical

Reducing boil time may result in:

Noticeable corn-like flavor

Off-aromas

Poor beer quality

TIANTAI kettle tuns include professional steam vent stacks and vapor management systems that efficiently remove DMS.

7. Additional Functions of the Boil

✔ Coagulation of proteins (hot break)

Creates clearer wort and improves stability.

✔ Sanitizing the wort

Boiling kills microorganisms, protecting the beer from infection.

✔ Enabling hop aroma additions

Each timing—60 minutes, 30 minutes, 10 minutes, 0 minutes, whirlpool—produces distinct aroma profiles.

✔ Preventing haze formation

Through protein precipitation.

✔ Driving faster cooling performance

Boiled wort cools more predictably because proteins and pH have been stabilized.

Can You Shorten Your Boil?

Yes—but only with caution.

Shorter boils may work for:

Low-gravity beers

Highly modified malt

Late-hop or no-hop styles (New England IPAs, fruity beers)

Small experimental batches

But traditional 60–90 minute boils are recommended for:

Lagers

Pilsners

High-adjunct mashes

High-gravity beers

Beers needing deep color or malt richness

Recipes requiring precise bitterness

If experimenting, track:

OG

Bitterness (IBUs)

pH

Flavor stability

Color

DMS levels

TIANTAI brewhouse systems allow full control of boil time, heat intensity, hop dosing timing, and evaporation rate, making experimentation easier and repeatable.

TIANTAI Brewery Equipment: Designed for Optimal Wort Boiling

TIANTAI specializes in turnkey microbreweries, craft breweries, and commercial brewhouses, providing complete brewhouse and cellar solutions.

Our brewing kettles offer:

Efficient steam or electric heating

Multi-layered insulation

Uniform heat distribution

Intelligent control systems

Professional-grade steam vent stack

Optional external wort boilers

High evaporation efficiency

Precision hop addition automation

We customize every system to your recipe needs—whether you prefer short experimental boils or traditional long boils.

Wort Boiling Deserves More Attention Than It Gets

While it’s tempting to shorten the brew day, the wort boil performs far too many essential functions to dismiss. From flavor development and bitterness creation to pH adjustment, sanitation, color formation, and clarity improvement, the boil profoundly shapes your final beer.

Experimenting is part of brewing—but understanding the science behind the boil ensures your experiments lead to great results.

TIANTAI Brewery Equipment is here to support your brewing success with professional brewhouse design, high-quality kettles, fermentation tanks, and complete turnkey systems.

If you’re planning a new brewery or upgrading your brewhouse, we warmly welcome your proposal.

Edited By Daisy

[email protected]