Wort whirlpooling is one of the most underestimated yet absolutely essential stages in modern beer brewing. While many new brewers view whirlpooling as nothing more than spinning hot wort to collect trub in the center of the kettle, the reality is much more sophisticated. Whirlpooling is deeply connected to wort clarification, hop utilization, aroma retention, bitterness control, brewhouse thermal efficiency, and even equipment design.

Whether you are brewing a classic lager, a hop-saturated hazy IPA, or a delicate wheat beer, your whirlpooling methods—and your equipment—play a major role in shaping your final beer quality.

In this complete guide, we’ll explore:

- The science behind wort whirlpooling

- Why whirlpooling is essential in both craft and industrial breweries

- Whirlpool temperatures and their effect on bitterness, aroma, and stability

- Different whirlpool hopping strategies

- Whirlpool vessel design and engineering

- Common operational issues and how to prevent them

How TIANTAI brewhouse systems improve whirlpool efficiency and beer quality?

Practical recommendations for new and professional brewers

This guide is written for craft brewers, commercial brewers, and serious homebrewers who want to gain professional-level understanding of whirlpooling and optimize their brewhouse performance.

1. What Is Wort Whirlpooling?

Whirlpooling is a separation and extraction stage that happens after wort boiling. After flame-out (or steam-off), the hot wort is rapidly circulated in the kettle or dedicated whirlpool vessel to create a rotational flow. When the circulation stops, the solids in the wort—including hop particles, hot break, coagulated proteins, and polyphenols—naturally gather in a tight cone in the center-bottom of the vessel.

This cone is often called:

trub pile

hop cone

whirlpool sediment bed

The clarified wort is then pumped from the side of the tank to the heat exchanger for rapid chilling and finally transferred into the fermenter.

Why is whirlpooling important?

Whirlpooling accomplishes several critical tasks:

Separates solid trub from clear wort

Prevents clogging of the heat exchanger

Improves beer clarity, stability, and mouthfeel

Allows controlled hop aroma extraction

Reduces vegetal flavors from hop matter

Helps in DMS volatilization (if temperature is still high)

Minimizes oxygen pickup after boiling

Without proper whirlpooling, issues such as hazy wort, unstable flavor, beer astringency, or fouled equipment can occur.

2. The Science Behind Whirlpooling

The whirlpool effect is based on a combination of centripetal force, fluid dynamics, and density differentiation.

When hot wort is pumped tangentially at high speed around the vessel wall, it rotates and creates a vortex. As the flow slows, heavier particles are pushed inward and settle into a cone shape in the center, where velocity is lowest.

This settling process is influenced by:

Particle size

Wort viscosity

Temperature

Tangential pumping velocity

Vessel diameter-to-height ratio

Retention/rest time

Brewhouse geometry is therefore deeply connected to whirlpool performance—something we’ll discuss in detail later.

3. Essential Functions of Whirlpooling

(1). Trub Separation

Whirlpooling is the most efficient post-boil separation method for:

Hot break

Coagulated proteins

Hop pellets

Polyphenols

Kettle finings (Irish moss, carrageenan)

A clean trub separation reduces protein-polyphenol haze and minimizes bitterness harshness.

(2). Hop Aroma Extraction (Whirlpool Hopping)

Modern craft breweries use whirlpooling as a major hop aroma extraction stage. At sub-boiling temperatures, hop essential oils dissolve into the wort without excessive isomerization of alpha acids.

This is critical for:

NEIPA

Hazy IPA

Cold IPA

Belgian ales

Hop-forward lagers

American pale ales

Whirlpooling has become a key part of “late hop” character without adding excess bitterness.

(3). Controlled Bitterness Development

Alpha acid isomerization slows dramatically below 85°C (185°F).

By adjusting whirlpool temperatures, brewers can customize hop flavor and bitterness ratios.

(4). Thermal Stability and DMS Reduction

Dimethyl sulfide (DMS)—which smells like cooked corn—is removed primarily during the boil. However, a short hot whirlpool helps drive off any remaining precursors.

(5). Heat Recovery and Energy Efficiency

A high-quality whirlpool efficiently moves wort through the heat exchanger without clogging, allowing for faster cooling and reduced energy usage.

4. Whirlpool Temperatures: What They Mean for Your Beer

Temperature during whirlpooling dramatically affects hop utilization and beer flavor.

Typical Whirlpool Temperature Ranges

| Temperature | Effects | Best For |

| 95–98°C (203–208°F) | Some alpha acid isomerization continues; mild bitterness increase; strong hop aroma extraction | West Coast IPA, pale ales |

| 85–90°C (185–194°F) | Reduced bitterness; high oil retention; citrus & tropical flavors preserved | NEIPA, hazy IPA, fruity ales |

| 70–80°C (158–176°F) | Minimal bitterness; extremely high aroma retention; soft, smooth hop character | Aroma-heavy styles, modern hopbombs |

| Below 70°C (158°F) | Mostly aroma preservation; very low volatilization | Delicate beers, low bitterness styles |

The choice of whirlpool temperature depends on your desired sensory profile.

5. Whirlpool Hop Techniques

5.1 Standard Whirlpool Hopping

Adding hops immediately after flame-out. Extracts aroma and some flavor without much bitterness.

5.2 Stateful Temperature Whirlpool

Cooling to a set temperature (e.g., 80°C) before adding hops ensures predictable extraction.

5.3 Multi-Step Whirlpool Hopping

Used for complex hop layering in modern IPAs:

First addition at 90°C

Second at 80°C

Third at 70°C

This produces depth, intensity, and layered complexity.

5.4 Whirlpool Hop Stand (Hop Soak)

Extending whirlpool time (20–60 minutes) to maximize aromatic oils.

6. How Long Should You Whirlpool?

Most breweries whirlpool for 10–30 minutes, but duration depends on:

Hop load

Wort clarity requirements

Vessel geometry

Temperature strategy

Commercial Guidelines

Large breweries: 10–15 minutes (highly efficient vessels)

Craft breweries: 15–30 minutes

IPA-focused breweries: 20–45 minutes for hop stands

Longer whirlpools improve aroma extraction, but increase thermal load and potential oxidation if not executed correctly.

7. Whirlpool Vessel Design and Engineering

Brewhouse engineering impacts whirlpool separation far more than many brewers realize.

Key design factors:

7.1 Tangential Inlet Angle

Most professional whirlpool vessels feature a specially designed side inlet that pumps wort into the tank at an angle. Poor inlet design causes: Turbulent trub piles, Unstable cone formation, Longer rest times, Incomplete sediment separation.

TIANTAI uses CFD-tested (computational fluid dynamics) tangential designs to ensure optimal rotational flow.

7.2 Vessel Geometry (Diameter to Height Ratio)

An ideal whirlpool has: Large diameter, Moderate height, Smooth bottom transition.

This enhances sediment collection and reduces wort losses.

7.3 Bottom Shape

A shallow “dish bottom” is preferred because it allows tight trub cone formation. Conical bottoms are NOT suitable for whirlpooling.

7.4 Vortex Breaker / Pickup Tube Design

A properly placed wort outlet ensures: Clear wort extraction, Minimal trub pickup, No pump cavitation.

This is a major advantage of modern TIANTAI whirlpool vessels.

7.5 Internal Rakes (Optional for Large Systems)

Large brewhouses (≥50 HL) sometimes include rakes for: Faster trub mound collapse, Denser cone formation.

TIANTAI can customize this feature for large-scale craft breweries.

8. Operational Tips for Successful Whirlpooling

8.1 Use a Strong but Controlled Pump Flow

Too strong = disturbed trub

Too weak = poor cone formation

A good starting range is 8–15 turnovers per hour, depending on system size.

8.2. Avoid Aeration

Aeration at high temperature causes: Hot-side oxidation, Staling, “Cardboard” flavors

A closed-loop TIANTAI system prevents oxygen pickup.

8.3. Use Kettle Finings

Whirlfloc or carrageenan improves: Protein coagulation, Trub separation, Wort clarity

Especially important for lagers or pilsners.

8.4. Allow Proper Rest Time

After turning off the pump, let the wort rest for 15–30 minutes.

8.5. Don’t Disturb the Trub Cone

Pump wort gently from the side pickup.

9. Common Whirlpool Problems & Solutions

| Causes | Solution | |

| 1. Poor Trub Cone Formation

|

Too much turbulence

Incorrect inlet angle Finings missing |

Reduce pump speed

Improve inlet design Add kettle finings |

| 2. Hazy Wort Entering Heat Exchanger | Insufficient rest time

Pickup tube too low |

Increase whirlpool rest time

Adjust pickup height |

| 3. Excessive Bitterness from Whirlpool Hops | Lower whirlpool temperature

Shorten hop stand time Adjust hop quantity |

10. How TIANTAI Brewhouse Systems Improve Whirlpool Efficiency?

TIANTAI is one of the leading manufacturers of craft brewery equipment, and our brewhouse engineering focuses heavily on whirlpool performance.

Key TIANTAI Advantages:

(1). Precision Tangential Inlet Design

Our whirlpool entry points are engineered using fluid dynamics to maximize rotational flow while preventing aeration.

(2). High-Efficiency Vessel Geometry

Optimized diameter-to-height ratio ensures fast, tight cone formation and minimal wort loss.

(3). Custom Pickup Tube & Vortex Breaker Designs

Guarantees consistent clear wort runoff—even in high hop-load breweries.

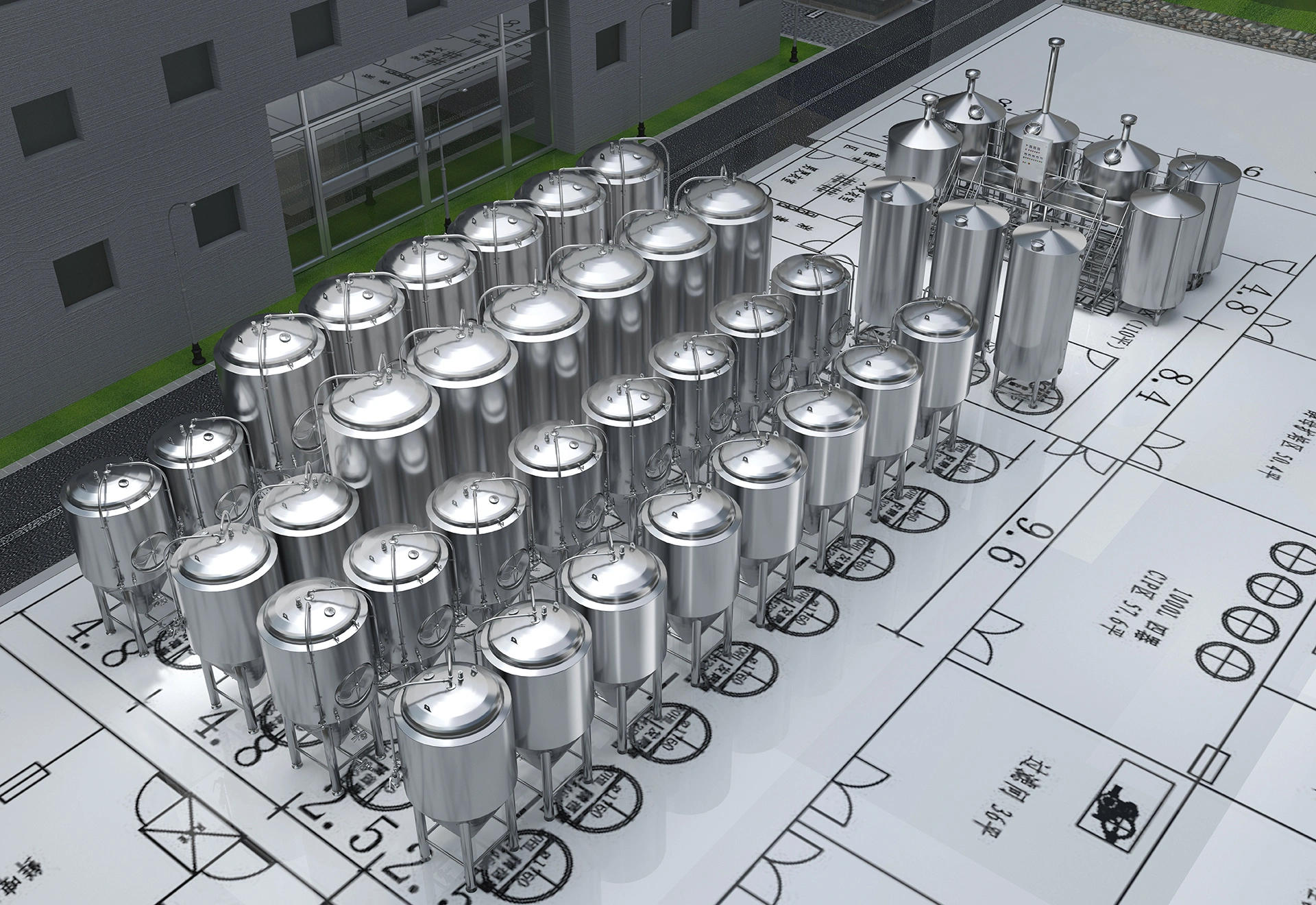

(4). Multi-Vessel Brewhouse Configurations

TIANTAI offers:

2-vessel (Mash/Lauter + Kettle/Whirlpool)

3-vessel (Mash + Lauter + Kettle/Whirlpool)

4-vessel (Mash + Lauter + Kettle + Whirlpool)

Larger systems benefit from a dedicated whirlpool vessel, dramatically increasing brewhouse output.

(5). CIP Cleaning & Sanitation Optimization

Whirlpool vessels include full drainage, polished surfaces, and CIP spray balls to eliminate residue and simplify cleaning.

(6). Custom Engineering for IPA-Heavy Breweries

For breweries producing NEIPA or hop-saturated beers, TIANTAI can customize:

Larger whirlpool volumes

Enhanced thermal control

Hop dosing ports

Reinforced pumps for high hop loads

11. Why Wort Whirlpooling Matters More Than Ever?

In modern craft brewing, whirlpooling is no longer just a trub-settling step. It is:

A hop extraction technique

A flavor and aroma development stage

A clarity and stability control point

A key factor in brewhouse efficiency

A crucial determinant of beer quality

Whether you’re optimizing hop aroma, preventing heat exchanger blockages, reducing hot-side oxidation, or upgrading your brewhouse system, whirlpooling deserves your full attention.

A well-designed whirlpool vessel—like the systems engineered by TIANTAI Brewery Equipment—can dramatically improve:

Wort quality

Hop efficiency

Clarity and stability

Flavor consistency

Overall brewhouse throughput

If you are planning to expand your brewery or upgrade your current brewhouse, TIANTAI can design a custom solution that perfectly fits your recipes, capacity goals, and required level of automation.

Want to Learn More or Start a Brewery Project?

TIANTAI provides:

Complete turnkey microbrewery systems

Professional brewhouse vessels (mash tun, lauter tun, kettle, whirlpool)

Fermenters and bright tanks

CIP systems

High-efficiency heat exchangers

Brewery layout and engineering support

On-site installation & training

We warmly welcome your questions and proposals. Let’s build your brewery together!

Edited By Daisy

[email protected]