Wort lautering is one of the most essential stages in the beer brewing process—yet also one of the most misunderstood. While lautering may look simple on the surface, it combines yeast biochemistry, grain physics, and equipment engineering in a delicate dance to extract clean sweet wort while leaving behind spent grains and unwanted solids. Proper lautering affects nearly everything downstream: brewhouse efficiency, flavor clarity, kettle boil performance, and even fermentation quality.

For commercial breweries and ambitious craft brewers, understanding how to lauter correctly—and how the design of your mash/lauter tun influences the process—is fundamental to producing consistent, high-quality beer. In this expanded guide, we explore the science of lautering, the most common challenges brewers face, and proven ways to optimize your lautering performance. We will also discuss how Tiantai’s advanced brewing systems can dramatically improve your mash filtration efficiency and overall brewhouse productivity.

What Is Wort Lautering?

Lautering is the process of separating sweet wort—the sugar-rich liquid produced in the mash—from the spent grains. The term originates from the German word läutern, which means “to clarify,” “to purify,” or “to refine.”

After the mash has completed its conversion (gelatinization and enzymatic starch conversion into fermentable sugars), the mash becomes a mixture of soluble sugars, insoluble grain husks, protein material, and fine particulates. Lautering uses the grain bed itself to act as a natural filtration medium.

Three Major Stages of Lautering

1.Mash Rest and Grain Bed Formation

▪The mash settles, allowing the grain husk layer to rise and form a natural filter.

▪Enzymes continue working slightly during this stage, especially if temperature-rest techniques like step mashing are used.

2.Vorlauf (Recirculation)

▪A portion of the wort is gently drawn off from the bottom and returned to the top until the runnings become clear.

▪This step sets the grain bed, clarifies the wort, and removes particulates.

3.Wort Runoff and Sparging

▪The brewer begins running the sweet wort into the kettle.

▪Simultaneously or subsequently, sparge water is applied to rinse remaining sugars out of the grains.

▪This can be done using fly sparging (continuous), batch sparging, or no-sparge techniques.

When successful, lautering yields clear wort with high extract efficiency and minimal risk of stuck mashes. But as any brewer knows, it doesn’t always go that way.

Why Lautering Can Be Challenging?

At first glance, lautering may seem like a simple mechanical task, but the physics behind it are surprisingly complex. Several factors interact during lautering:

✦Grain particle size

✦Grain bed depth and compaction

✦Mash thickness

✦Amount of beta-glucans and gum-like proteins

✦Equipment geometry and false-bottom design

✦Flow rate and hydrostatic pressure

✦Uniformity of sparge water distribution

The result? Even experienced brewers sometimes struggle with slow runoffs, cloudy wort, or the dreaded stuck mash—a situation where flow stops completely due to grain bed compaction or particulate clogging.

The good news is that with good process control and the right equipment, lautering becomes predictable and efficient.

Three Key Tips for Smooth, Efficient Lautering

Below we expand your original three core points into a deeper, more comprehensive guide with actionable detail for both homebrewers and commercial operators.

Firstly, Check Your Crush—The Foundation of a Good Lauter

The grist crush is arguably the most important factor in lautering performance. During milling, the grain kernel must be broken apart to expose the starchy endosperm while keeping the husk as intact as possible.

Why the Crush Matters?

Intact husks = better natural filtration.

Over-crushed grain = higher extract, but higher risk of stuck mash.

Too coarse = poor extract efficiency and wasting malt.

Balancing extraction and lautering ease is the brewer’s eternal challenge.

Ideal Milling Goals

A well-optimized crush should yield: Fully cracked kernels, Husks that are mostly still whole, Moderate amount of coarse grits, Minimal flour (too much flour causes compaction)

Grain Types Also Affect Lautering

Some malts naturally resist lautering because of high beta-glucan content or small kernel size:

Wheat – no husk at all

Rye – high gum-like protein levels

Oats – high viscosity and beta-glucans

Unmalted adjuncts – often gelatinize differently

These grains increase the risk of stuck mashes and may require special handling, as discussed later.

Practical Advice

Experiment with different mill gap settings over time.

Use a two-roller or four-roller malt mill for consistent results.

For commercial breweries, consider a wet-milling system, which preserves husk integrity even better.

Tiantai’s brewhouse systems can be equipped with precision malt mills and optional wet milling solutions to help ensure both excellent extract efficiency and smooth lautering.

Second, Lauter as Slowly as Necessary—Speed Kills (the Lauter)

One of the fastest ways to ruin a lauter is to rush it. New brewers often assume they can speed up production by opening the mash/lauter tun valve fully—only to experience a sudden flow slowdown or a complete stuck mash.

Why Slow Lautering Works?

The lautering process relies on gravity and capillary flow through the grain bed. If wort is drawn off too quickly:

▪The grain bed compacts tightly.

▪The false bottom experiences uneven suction.

▪Channels form in the mash, reducing extraction.

▪Stuck mash risk increases dramatically.

Tiantai Provides You Proper Lautering Technique

1.Start Slowly: Open the valve just enough to establish a trickle. Allow the grain bed to settle and self-filter.

2.Monitor Turbidity, if the wort becomes cloudy, slow down the flow or pause to recirculate.

3.Increase Flow Gradually. Once the bed is set, increase flow incrementally while observing the runoff clarity and speed.

4.Avoid Creating Vacuum Zones. An uneven flow creates localized suction that collapses the bed.

In a commercial brewhouse, automated valve control and rakes help ensure even flow, steady bed compaction, and consistent runoff. Tiantai’s lauter tuns are engineered with precisely designed rake arms, adjustable speeds, and optimized false-bottom geometry to maintain optimal filtration performance.

Third, Use Rice Hulls When Needed—The Lautering Helper for Difficult Grists

Rice hulls are one of the simplest and most effective tools for preventing stuck mashes when brewing with grains that lack husk material or contain high levels of gums.

How Rice Hulls Work?

They add structural porosity to the mash.

They prevent compacting by increasing bed permeability.

They are inert, flavorless, and do not affect beer chemistry.

When to Add Rice Hulls?

Use rice hulls for: Wheat beers (Hefeweizen, Witbier)

Oat-rich recipes (Oatmeal Stout, NEIPA)

Rye beers (Roggenbier, Rye IPA)

High-adjunct beers (American Light Lager)

How Much to Use?

0.5 to 1 lb per 5-gallon batch for home brewing

1–5% of the total grist for commercial brewing

Rice hulls behave like dietary fiber for the mash—giving it more structure and reducing viscosity.

A Deeper Look at Lautering Equipment and System Design

The geometry, engineering, and build quality of the mash/lauter tun dramatically affect lautering performance. Two systems may use the same grist and recipe but produce completely different results due to equipment design.

Here are the key elements that matter:

1. False Bottom and Filter System

A good false bottom must: Provide maximum surface area, Allow even wort distribution, Resist clogging, Maintain structural rigidity under hydrostatic pressure.

Tiantai engineers false bottoms with precision-cut, wedge-wire or perforated-plate designs to maximize filtration efficiency and minimize dead spaces.

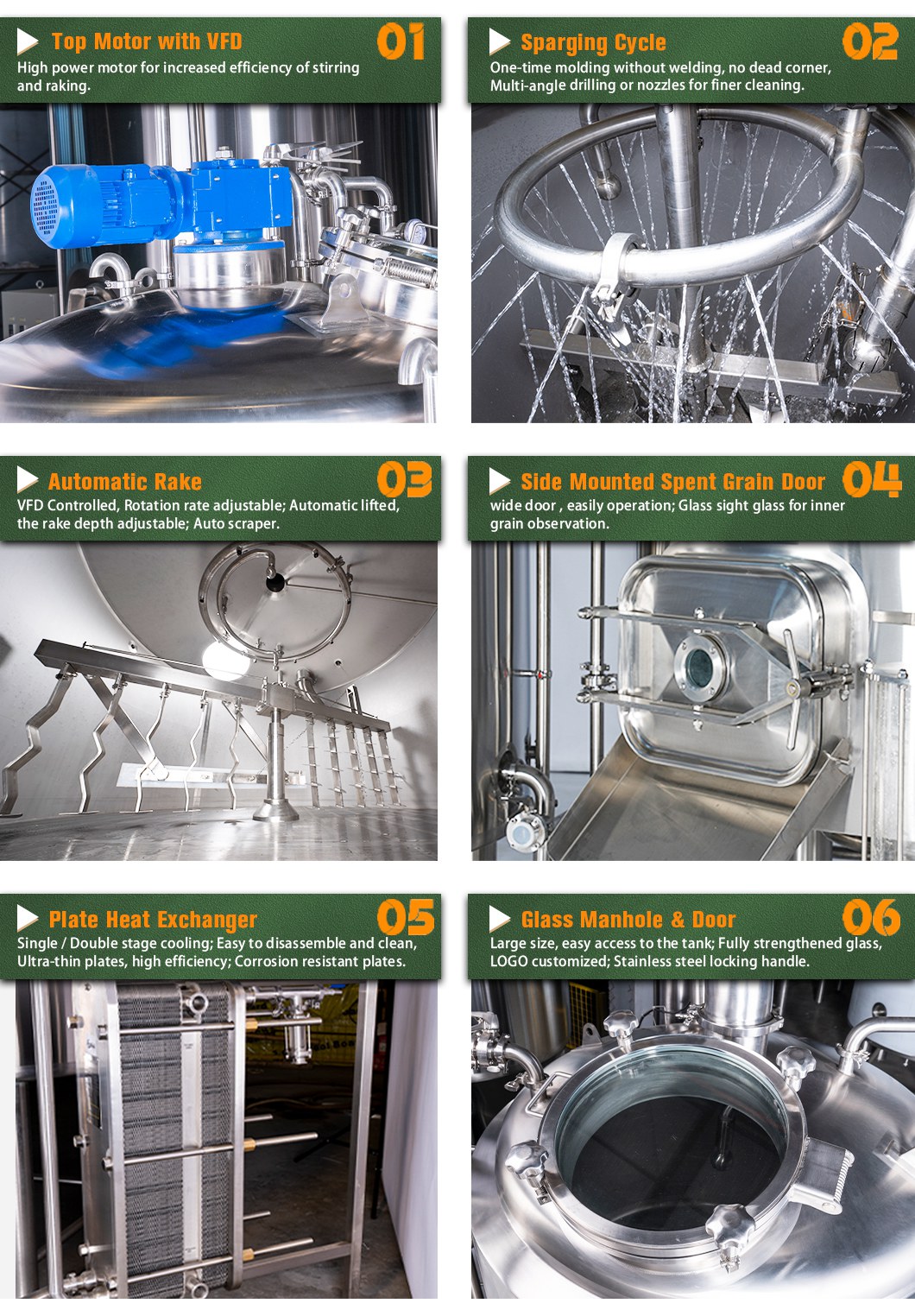

2. Lauter Rakes and Motors

Rakes are not meant to “stir” the mash, but rather: Gently loosen the top layer, Prevent compacting, Maintain uniformity, Assist in grain-out after lautering is complete.

Automated rake height control is especially helpful in larger systems.

3. Sparging Mechanism

Uniform sparging is crucial for good extraction and clear runoff. Desired features include: Rotary sparge arms, Fine spray nozzles, Controlled flow and temperature, Even distribution coverage.

Improper sparging creates channeling, reduces brewhouse efficiency, and can disturb the grain bed.

4. Lauter Tun Sizing and Bed Depth

Bed depth affects: Extraction, Runoff rate, Compaction risk

A tun that is too shallow or too tall for the recipe can cause performance issues. Tiantai offers customizable brewhouse designs to match your production volume and grain bill requirements.

Common Lautering Problems and How to Fix Them

1. Stuck Mash

Causes: Too fine crush, High beta-glucan grains, Too fast runoff, Equipment clogging

Solutions: Add rice hulls, Stir gently with rakes (commercial systems), Recirculate and restart slow, Adjust mill gap for next time.

2. Slow Runoff

Causes: Partial compaction, High mash viscosity, Dull or clogged false bottom.

Solutions: Increase sparge temperature slightly (not above 78°C / 172°F), Use a rest at 40–45°C for problematic malts, Clean false bottom thoroughly after each brew.

3. Cloudy Wort

Causes: Inadequate vorlauf, Too aggressive sparging, Disturbed grain bed.

Solutions:Recirculate longer, Slow down sparging and runoff, Check false-bottom seals and alignment.

How Tiantai Brewing Equipment Helps Improve Lautering?

Tiantai Brewing Equipment specializes in custom-designed brewhouse systems that optimize mash filtration and ensure consistent, trouble-free lautering. Whether you operate a microbrewery, mid-size commercial brewery, or an industrial-size facility, Tiantai provides:

✔ Precision-engineered mash/lauter tuns

✔ Advanced false-bottom filtration systems

✔ Automated rake systems with adjustable height

✔ Efficient sparge arms and water distribution

✔ Custom milling solutions

✔ Complete turnkey brewery setups

These systems are designed to increase brewhouse efficiency, reduce lautering time, minimize stuck mash risk, and produce clearer wort—all with durable, sanitary stainless-steel fabrication.

Brewers who switch to Tiantai often report:

▪Higher brewhouse efficiency

▪More consistent wort clarity

▪Faster and smoother lautering cycles

▪Reduced labor and manual intervention

▪Better control of their mash and sparge processes

If you’re planning to build or expand your brewery, Tiantai’s engineering team can provide full layout design, equipment sizing, piping diagrams, and cost estimates to suit your production goals.

Lautering is both an art and a science. While the principles appear simple—use the grain bed to filter the wort—the real-world challenges require understanding the interplay between milling, flow rate, grain composition, and equipment design.

By optimizing your crush, moderating your runoff speed, using rice hulls when needed, and investing in professionally engineered lautering equipment, you can dramatically improve your wort clarity, brewhouse efficiency, and overall beer quality.

Whether you’re a startup brewery or an established production facility, Tiantai’s mash/lauter tun solutions are designed to support smooth, efficient lautering at any scale. For customized proposals, equipment quotes, or technical guidance on brewery setup, Tiantai welcomes your inquiry at any time.

Edited By Daisy Cai

[email protected]