As more breweries and beverage producers expand into spirits production, the demand for flexible, efficient, and flavor-driven distillation systems continues to grow. Distillation Spirits Producers: Two of the most popular solutions in modern craft distilling are the thumper distillery system and the hybrid distillery system. While both systems aim to improve efficiency and product diversity, they serve different production philosophies and operational goals. Understanding how each system works—and what it is best suited for—can help distillers make smarter investment decisions and unlock greater creative potential.

Thumper Distillery Systems vs. Hybrid Distillery Systems

What Is a Thumper Distillery System?

A thumper distillery system is a traditional pot still configuration enhanced with one or more thumpers (also known as retorts). A thumper is a secondary vessel connected between the primary pot still and the condenser.

During distillation, alcohol vapor from the main kettle is routed into the thumper, where it bubbles through a liquid charge—typically water, low wines, high wines, or a flavored solution. This causes the vapor to condense and re-vaporize, effectively performing a secondary distillation within a single run.

Key Characteristics of a Thumper System:

*Based on pot still distillation

*Improves ABV without a second full distillation

*Retains rich congeners and flavor compounds

Can be configured as single thumper or double thumper (double retort)

Advantages of a Thumper Distillery System

1. Improved Efficiency Without Losing Character

A traditional pot still may only reach 35–45% ABV in one pass. Adding a thumper allows the distiller to achieve higher proof while preserving the heavy, complex flavors associated with pot-stilled spirits.

2. Reduced Energy and Labor Costs

Compared to running two separate distillations, a thumper system:

Uses less total heating energy

Requires fewer cleaning cycles

Reduces overall man-hours

3. Flavor Customization

Thumpers can be charged with:

Water

Alcohol

Botanicals

Fruit or flavoring components

This makes them especially valuable for rum, brandy, whiskey, and gin, where flavor development and ester formation are desirable.

4. Ideal for Traditional Spirits

Thumper systems are particularly well suited for:

Pot-stilled whiskey

Heavy and ester-forward rum

Fruit brandies

Botanical-forward gins

What Is a Hybrid Distillery System?

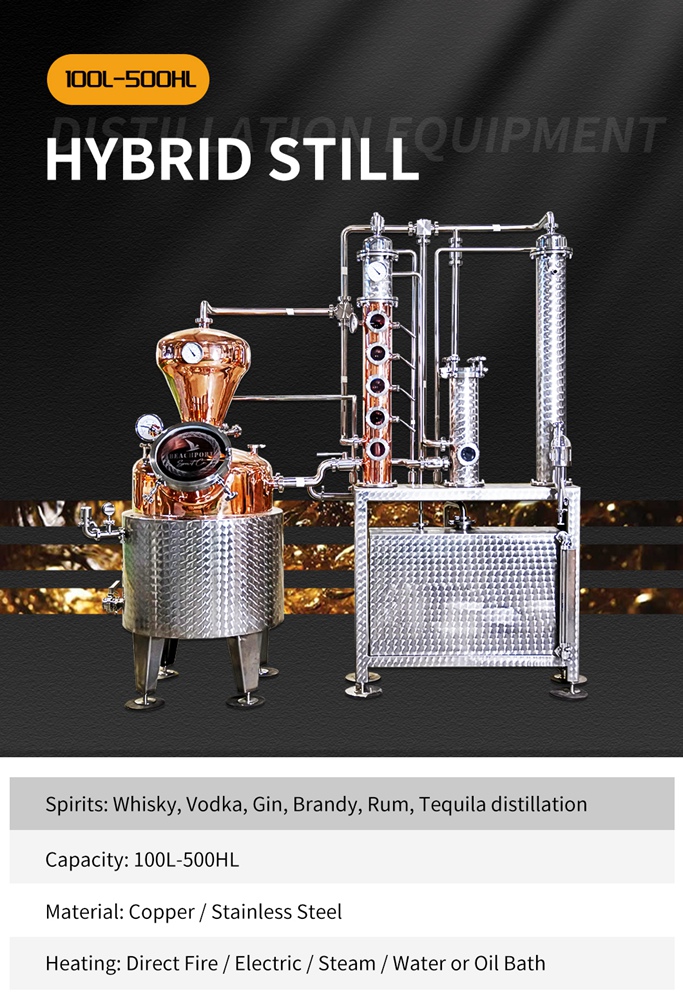

A hybrid distillery system combines multiple distillation technologies into a single, highly adaptable platform. Typically, it integrates:

A pot still base

A column still section (plates or packed column)

Modular vapor path control via valves

The defining feature of a hybrid system is its ability to switch between pot still and column still operation, or combine both during the same run.

Advantages of a Hybrid Distillery System

1. Maximum Product Flexibility

A hybrid system allows producers to make:

Pot-stilled whiskey, rum, and brandy

Botanical gin

Vodka and neutral spirits

Flavored and infused spirits

All within a single piece of equipment.

2. Adjustable Purity and Flavor

By controlling the number of plates, reflux ratio, and vapor path, distillers can fine-tune:

ABV

Mouthfeel

Aroma intensity

Congener retention

This level of control is ideal for producers who want to experiment across multiple spirit categories.

3. Faster Production for Neutral Spirits

Unlike a traditional pot still, a hybrid system can achieve high-proof alcohol (90–96% ABV) in a single run, making it far more efficient for vodka and base alcohol production.

4. Ideal for Brewery–Distillery Operations

Hybrid systems are especially attractive to breweries entering distillation because they:

Integrate well with existing fermentation infrastructure

Support small-batch experimentation and full-scale production

Reduce the need for multiple stills

Thumper System vs. Hybrid System: Key Differences

| Feature | Thumper Distillery System | Hybrid Distillery System |

| Base Design | Pot still + retort(s) | Pot still + column |

| Flavor Profile | Rich, heavy, traditional | Adjustable: rich to clean |

| ABV Capability | Medium–high | Medium to very high |

| Neutral Spirits | Not ideal | Excellent |

| Energy Efficiency | Moderate | High |

| Product Range | Focused | Very broad |

| Complexity | Lower | Higher |

Can Thumpers and Hybrid Systems Be Combined?

Yes—and this is where modern distillery design becomes especially powerful.

Advanced hybrid systems can be equipped with:

Single or double thumpers

Rectifying columns

Botanical baskets

Multiple condensers

Valved vapor manifolds

With proper valve control, a single system can operate as:

A traditional pot still

A pot still with single or double thumper

A short column still for flavored spirits

A full rectification system for neutral alcohol

This level of flexibility allows producers to adapt to market demand without additional capital investment.

Which System Is Right for You?

Choose a thumper distillery system if:

Your focus is on traditional, flavor-forward spirits

You value heritage distillation methods

You want complexity without excessive automation

Choose a hybrid distillery system if:

You want to produce multiple spirit types

You need high-proof neutral alcohol

You value operational efficiency and scalability

For many modern craft producers, the best solution is a custom hybrid system with thumper integration, offering both tradition and innovation in one platform. The future of craft distilling lies in flexibility, efficiency, and creativity. Whether through a classic thumper system or a modern hybrid distillery setup, today’s distillers have more tools than ever to shape flavor, optimize production, and expand their portfolios. The right system doesn’t just make spirits—it enables growth.

Edited By Daisy

[email protected]