With reliable and hygienic Tiantai brewery equipment, brewing sour beer becomes a stable and rewarding process, even for micro and craft breweries. Sour beer is a unique style of beer that is intentionally brewed to deliver a refreshing tart or acidic flavor. This characteristic sourness is usually created through the controlled use of bacteria such as Lactobacillus or Pediococcus. Popular sour beer styles include Berliner Weisse, Gose, and Flanders Red, all of which are increasingly popular among craft beer lovers worldwide.

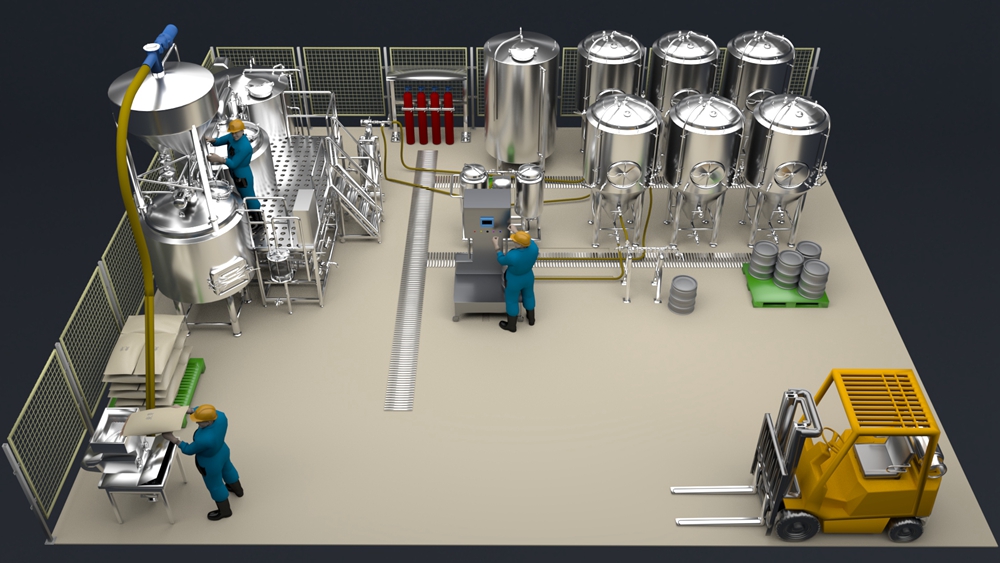

Below is a practical step-by-step guide on how to brew sour beer using Tiantai micro brewery equipment.

Step 1: Choose a Sour Beer Recipe

There are many styles of sour beer, each with different levels of acidity and flavor complexity. Before brewing, select a recipe that suits your target market and brewing capability. Berliner Weisse and Gose are ideal for beginners, while Flanders Red requires longer aging and more advanced control.

Step 2: Mash and Boil in the Brewhouse Equipment

Use Tiantai brewhouse equipment to mash the grains and boil the wort just as you would for any standard beer. Precise temperature control and efficient heat transfer ensure a clean and consistent wort, which is especially important for sour beer production.

Step 3: Pitch Yeast and Bacteria

After cooling the wort to the appropriate temperature, pitch the brewing yeast first. Then introduce your selected bacteria strain, such as Lactobacillus or Pediococcus.

With Tiantai fermenters, you can choose different souring methods:

Add bacteria directly into the fermenter

Use a kettle souring or sour mash technique before boiling

The flexibility of Tiantai micro brewery equipment allows brewers to experiment with different sour beer processes safely and efficiently.

Step 4: Fermentation in Beer Fermenting Vessels

Ferment the beer in Tiantai beer fermenting vessels under controlled conditions. Sour beers typically require longer fermentation times compared to conventional beers. During this stage, bacteria continue producing acidity, so regular pH monitoring is recommended to achieve the desired flavor balance.

Step 5: Aging for Flavor Development

Once primary fermentation is complete, transfer the beer to a secondary fermenter, cellar tank, or brite tank for aging. Aging may take several months and is crucial for developing complex sour flavors and aroma depth. Tiantai stainless steel tanks provide excellent sealing and sanitation, ensuring stable aging conditions.

Step 6: Bottling or Kegging

Finally, bottle or keg the sour beer using appropriate carbonation levels. Sour beers often require higher carbonation to enhance their refreshing character. With Tiantai’s professional brewery equipment, carbonation control remains precise and consistent.

Why Choose Tiantai Sour Beer Brewing Equipment?

Brewing sour beer requires strict hygiene and reliable process control. Tiantai brewery equipment is designed with:

Food-grade stainless steel

Easy cleaning and CIP systems

Accurate temperature and pressure control

Custom solutions for craft and micro breweries

Whether you are starting a new sour beer line or expanding your craft beer portfolio, Tiantai micro brewery equipment provides a dependable foundation for high-quality sour beer production.

Emily Gong