Let’s learn firstly what’s the cold brew coffee? Cold brew coffee is exactly what it sounds like: coffee that’s brewed cold. The “cold” part refers to the brewing process, not the serving temperature. You can actually enjoy cold brew hot or cold.

That might sound straightforward, but a lot of people confuse cold brew with iced coffee.

Iced coffee is any coffee that’s brewed hot, then chilled and poured over ice. Cold brew is made by steeping ground coffee in cold water, right from the start.

Cold coffee—especially cold brew—has become one of the fastest-growing products in the beverage industry. From cafés to large-scale bottling plants, the demand for smooth, naturally sweet, low-acidity cold coffee continues to rise. As a result, many manufacturers are now shifting from small-batch brewing to commercial-scale extraction systems that offer efficiency, repeatability, and consistent flavor quality.

Among the equipment manufacturers serving this growing market, Tiantai has developed a dedicated Cold Coffee Brewing System, designed specifically for industrial production. Our system is based on brewing technologies used in the beer and beverage industries, offering precise temperature control, sanitary stainless-steel vessels, effective filtration, and CIP-cleaning integration.

This article will give you a complete, step-by-step guide to making cold coffee with a Tiantai brewing system—from selecting beans and grind size, to extraction, filtration, packaging, and quality control. If you are planning to enter the cold coffee market or upgrade your production capacity, this guide will help you understand both the process and the equipment involved.

1. What Makes Tiantai’s Cold Coffee Brewing System Special?

Before getting into the step-by-step process, it’s important to understand what sets Tiantai’s cold brew system apart from simple immersion tanks or makeshift brewery adaptations.

1.1 Hygienic, industrial-grade design

Tiantai manufactures equipment primarily for the beer, kombucha, and functional beverage industries. This means:

▪All tanks are food-grade 304/316 stainless steel

▪Welds, joints, and fittings are sanitary

▪Surfaces are polished for easy cleaning and CIP compatibility

▪All piping uses tri-clamp connections, easy operation

This is essential for large-scale cold coffee production, where microbial stability and sanitary design directly impact shelf life.

1.2 Controlled cold extraction

Cold coffee flavor depends heavily on maintaining the correct extraction temperature. Tiantai uses:

▪Jacketed extraction vessels

▪Glycol chillers or ice-water chillers

▪Automatic temperature control

This ensures extraction stays within the ideal 4–8°C range, which prevents bitterness and preserves delicate coffee aromatics.

1.3 Flexible batch sizes

Tiantai can build cold coffee systems from: small 50 L pilot tanks to 10,000 L production systems.

This range allows companies to scale gradually while maintaining the same process and flavor profile across different capacities.

1.4 Built-in filtration options

Sediment control is crucial for cold brew stability. Tiantai systems typically include:

▪Bag filters

▪Plate & frame filters

▪DE filters (diatomaceous earth)

▪Cartridge fine filters

This ensures your cold coffee is clear, stable, and smooth.

1.5 CIP cleaning

A complete Cleaning-in-Place (CIP) system is integrated, eliminating manual scrubbing and ensuring sanitary production after every batch. Together, these features make Tiantai’s cold coffee system suitable not only for cafés and small roasteries but also for RTD beverage factories, co-packers, and large bottling plants.

2. Choosing the Right Coffee for Cold Brew Production

The quality of your cold coffee begins long before it enters the extractor. Coffee bean selection, roast profile, and grind size all influence the final flavor.

2.1 Bean variety

Both Arabica and Robusta can be used, but most premium cold brews use:

▪100% Arabica

▪Medium or medium-dark roast

▪Beans with chocolate, nutty, caramel, or fruity notes

Highly acidic beans are less suitable since cold extraction already reduces acidity.

2.2 Roast profile

A roast that is too light can produce grassy or sour flavors in cold extraction. Most producers choose:

▪Medium roast for balanced flavor

▪Medium-dark roast for rich, chocolatey cold brew

▪Dark roast for bold, strong concentrates

2.3 Grind size

The ideal grind size is similar to coarse sugar or French press grind.

Too fine → over-extraction, clogged filters

Too coarse → weak, watery brew

Consistency in grind size is essential in large-scale systems to avoid extraction variation.

3. Step-by-Step Cold Coffee Brewing Process Using a Tiantai Brewing System

Now let’s dive into the full workflow—from raw ingredients to finished cold brew.

Step 1: Prepare the Coffee Grounds

Once you choose the bean and roast profile, grinding is the first operational step.

Recommended grind size: 800–1200 microns, depending on roast level.

Coffee-to-water ratio: For commercial-grade cold brew concentrate 1:8 to 1:12 (coffee : water by weight). For ready-to-drink cold coffee 1:14 to 1:18

If you need a stronger product for dilution or nitrogen infusion, a 1:8 ratio produces a robust concentrate that maintains flavor even after mixing.

Step 2: Load the Coffee Into the Extraction Tank

Tiantai extraction tanks typically include: A removable stainless-steel filter basket, or A giant mesh bag-type filter, or A perforated extraction chamber.

These options avoid coffee grounds floating freely in the tank, which accelerates filtration and prevents clogging.

Loading procedure: Sanitize the tank (CIP or hot rinse), Insert the basket or filter bag, Pour coffee grounds evenly to maximize extraction surface contact. Close the manway tightly to maintain temperature.

Step 3: Add Water and Begin Extraction

Fill the tank with chilled water or let the chiller bring the water down after filling.

Ideal extraction temperature: 4–8°C (39–46°F)

Cold temperatures minimize bitterness and slow extraction, producing a smoother taste.

Extraction duration: 10–18 hours depending on Roast level, Grind size, Strength target, Coffee-to-water ratio, Agitation options.

Some Tiantai tanks include slow-speed agitators. Gentle stirring every 30–60 minutes helps even extraction. Avoid vigorous mixing (can cause harsh flavors).

If the system is non-agitated, natural immersion works fine; extraction simply takes longer.

Step 4: Drain and Filter the Cold Coffee

Once extraction is complete, the coffee must be filtered to remove sediment, oils, and micro-particles.

Filtration options in Tiantai systems include:

4.1 Bag filter (coarse filtration), Captures large coffee particles.

4.2 Plate and frame filter. Uses filter sheets (1–25 microns) to remove fines and solids.

4.3 DE filter (diatomaceous earth). Used in high-volume production to achieve very fine clarity, stable shelf life, and smooth mouthfeel.

4.4 Cartridge filter. Optional final-step filtration for RTD packaging.

After filtration, the cold brew is transferred to a holding tank, keeping it chilled and protected from oxidation.

Step 5: Cooling, Holding, and Storage

To maintain freshness and shelf life, cold brew must be stored properly.

Tiantai holding tanks include: Double jacket for cooling; CO₂ or nitrogen blanketing (optional); Sanitary sight glass; Level control; Cooling sensors; Recommended storage temperature 0–4°C

With this temperature and good filtration, cold brew can remain stable from 10–14 days without preservatives, 30–60 days with pasteurization or aseptic processing, 90 days or more with nitro infusion and ultra-fine sterile filtration

Step 6: Packaging Options

Depending on your market and production scale, Tiantai systems integrate easily with Glass bottling lines, Aluminum canning lines, Bag-in-box filling systems, Kegging lines, Aseptic filling machines.

For RTD cold brew: Dilute your concentrate to the target flavor strength.

For Nitro cold brew:Use a carbonation stone or nitrogen-infusion module to saturate the cold brew with nitrogen for a creamy mouthfeel.

Step 7: CIP (Cleaning-in-Place) After Each Batch

Hygiene is essential. Tiantai provides fully integrated CIP systems with Hot water→Caustic cleaning (1–2%) → Acid cleaning (0.3–0.7%) → Sanitizing rinse (peracetic acid or hot water) → Standard CIP sequence → Pre-rinse with hot water → Caustic cycle at 60°C →Rinse →Acid cycle → Final rinse → Chemical or thermal sanitizing.

Proper CIP ensures consistent flavor, longer equipment lifespan, and compliance with beverage safety standards.

4. Cold Brew Quality Control Checklist

To maintain a stable, high-quality cold brew, monitor these parameters regularly: Flavor and aroma testing, Clarity, Sweetness, Acidity, Body, Any off-flavors, Chemical parameters, pH (typically 4.6–5.2 for cold brew), Total dissolved solids (TDS), Brix, Extraction yield, Microbiological tests, Total plate count, Yeasts and molds, Shelf life monitoring, Color stability, Sediment formation, Flavor degradation.

5. Why Choose Tiantai for Cold Coffee Production?

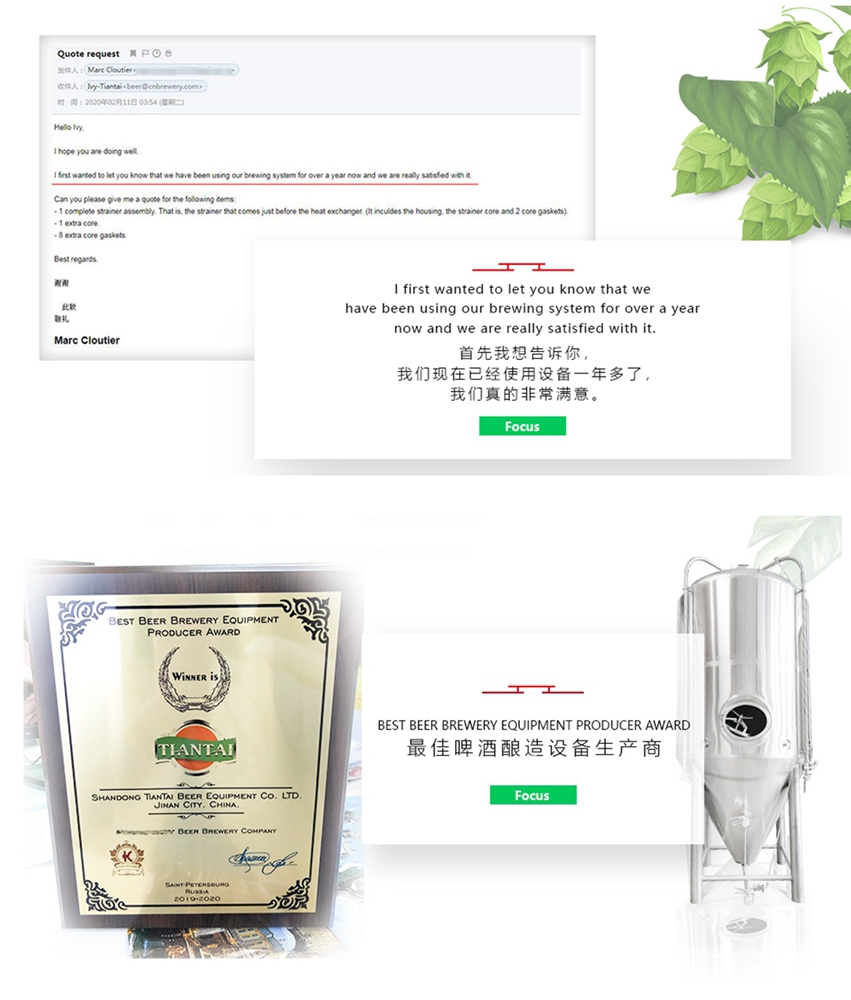

Tiantai has been producing beverage equipment for over 20 years, originally focusing on breweries and kombucha factories. Our background gives us three major advantages:

5.1 Precision engineering

Coffee extraction benefits from the same precision needed in brewing beer—temperature accuracy, stainless-steel sanitation, and control automation.

5.2 Customization

Tiantai designs systems based on: Batch size, Flavor requirements, Plant layout, Budget, Operators’ experience.

This ensures you get equipment tailored to your production reality.

5.3 Full factory solutions

Tiantai offers turnkey solutions: Plant layout, Piping and utilities, Chillers and cold rooms, Filtration packages, Packaging lines, Operator training.

This makes it easy to scale from a small 200 L/day workshop to a 10,000 L/day industrial cold brew plant.

6. Crafting Premium Cold Coffee at Industrial Scale

Making cold coffee using the Tiantai cold brew system combines craftsmanship with industrial precision. At its heart, the process is simple—coffee, water, time, and temperature—but the details matter. Control over extraction temperature, grind size, sanitation, and filtration distinguishes premium cold coffee from inconsistent small-batch products.

With a Tiantai system, you gain: Consistency-Efficiency-Scalable capacity-Long-term operational savings-Food-grade safety compliance.

Whether you want to produce cold brew concentrate, RTD bottled coffee, or nitro cold brew on tap, Tiantai offers the equipment and process design to help you grow your market.

Edited By Daisy Cai

[email protected]