The tunnel-type pasteurizer is a high-efficiency solution designed for continuous thermal processing of bottled beverages, including beer, kombucha, juices, and other drinks. Capable of processing 1000 bottles per hour depending on bottle size, it provides a reliable and consistent method to ensure product safety while preserving flavor and quality.

Bottles enter the machine at 3°C and are gradually heated to 35°C by the end of the process. The sterilization section maintains a constant temperature of 63°C, with precise control within ±1°C, ensuring uniform pasteurization. The sterilization zone spans 2400 mm, allowing an adjustable dwell time of 17 minutes, while the total cycle completes in 43 minutes. The effective width of 920 mm accommodates multiple rows of bottles, increasing throughput and flexibility.

The system is equipped with four warming water pumps (3T/h) and four hot water pumps (6T/h) to ensure stable circulation. A DN25 pneumatic diaphragm valve controls the temperature automatically, while the PLC-controlled electrical cabinet offers intelligent operation, monitoring, and adjustment. Bottles are smoothly transported via infeed and outfeed conveyor belts, with speeds adjustable from 110 to 553 mm/min.

Heating is supplied through 0.2–0.4 MPa steam, combined with 6 m³ of circulating hot water, providing uniform thermal distribution. All components that contact water and bottles—including the frame, conveyor belt, and spray nozzles—are constructed from SUS304 stainless steel, ensuring durability, hygiene, and corrosion resistance.

Measuring 7000 × 1350 × 1650 mm, this tunnel pasteurizer combines a compact footprint with high throughput and precise control, making it an ideal choice for modern beverage production lines that demand efficiency, consistency, and product safety.

| Pasteurization tunnel machine | Speed: 1000-1300 bottle per hour(depends on the volume) |

| Inlet bottle temperature:3℃ | |

| Outlet bottle temperature:35℃ | |

| Sterilization temperature: 63℃ | |

| Temperature-controlled precision: ±1℃ | |

| Sterilization length:2400mm | |

| Sterilization time:17min, adjustable | |

| Total Sterilization time: 43 min | |

| Sterilization effective width: 920 mm | |

| Device: warming water pump:3T/h 4pcs; hot water pump :6T/h 4pcs; Pneumatic diaphragm valve from temperature control:DN25; Electrical control box PLC control system: 1 set; Into and out of the conveyor belt |

|

| Conveyor speed:110-553mm/min | |

| Heating steam pressure:0.2Mpa | |

| heating circulating water:6m3 | |

| Using steam pressure: 0.2-0.4mpa | |

| Material: machine, belt and nozzle is SUS304 | |

| Dimensions(L×W×H):7000×1350×1650mm |

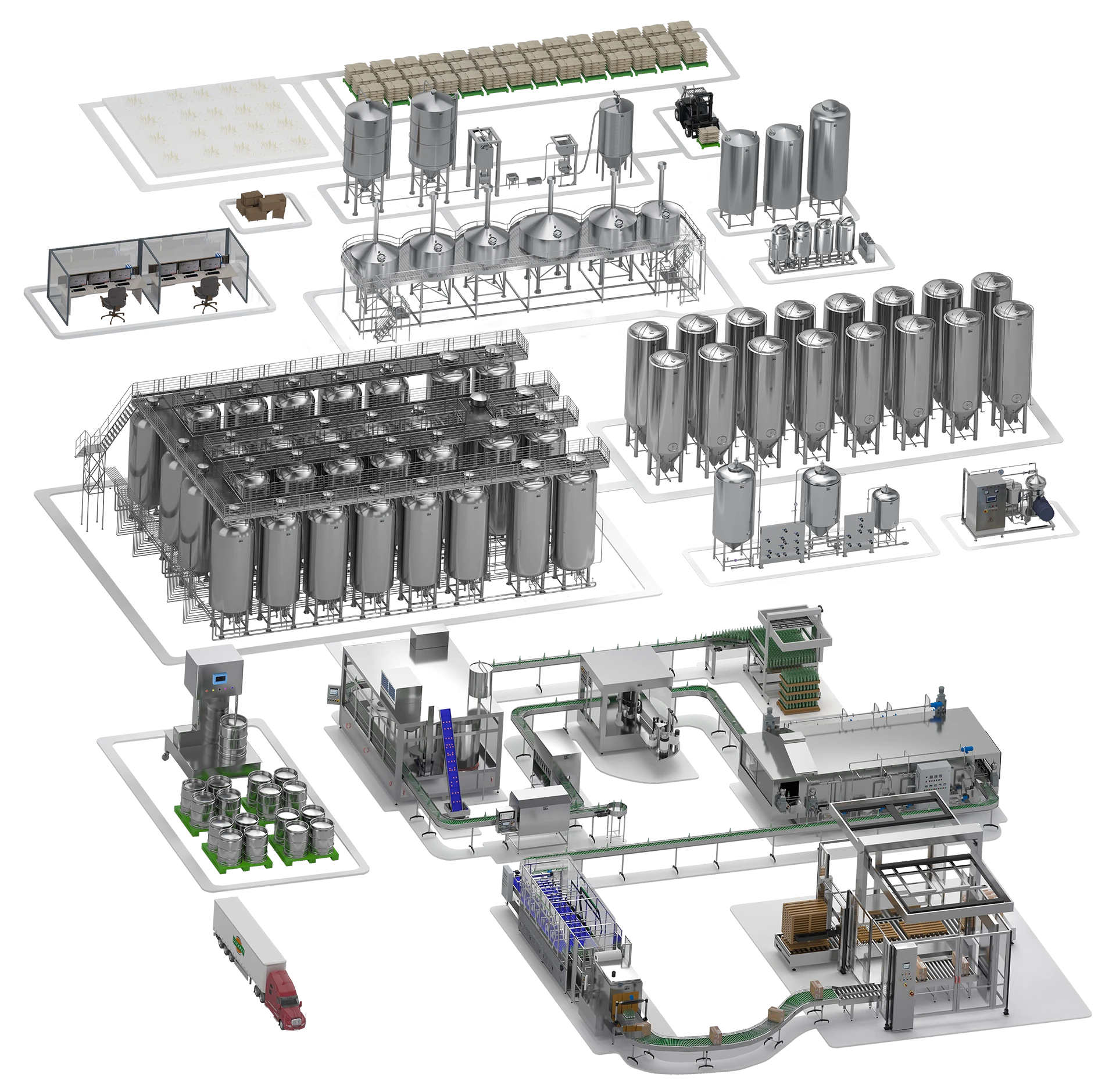

TIANTAI: Your End-to-End Brewery Partner

-

Full-Service Expertise: As your general contractor, we provide complete turnkey solutions, from design to global project completion.

-

Optimized Systems: We manufacture precisely matched, energy-efficient brewhouses that prioritize your economic ROI.

-

Proven Results: Leverage our decades of experience to maximize process uptime, reduce beer loss, and brew flavor-rich beers consistently.

Contact Hubert to optimize your brewery’s potential now!

Hubert

Email: [email protected]