1.1200L Brewhouse System Introduction

TIANTAI 1200L Brewhouse System is built for serious craft brewers who demand efficiency, consistency, and scalability. Designed for mid- to large-scale beer production, this system offers the ideal balance between production volume and operational flexibility. With a daily output of up to 2400–3600 liters, TIANTAI 1200L brewhouse system is perfect for breweries expanding to meet rising demand or entering new regional markets.

Engineered with durability, automation options, and European-standard craftsmanship, the 1200L brewhouse supports a full range of beer styles, from lagers and ales to specialty and seasonal brews.

2.Features

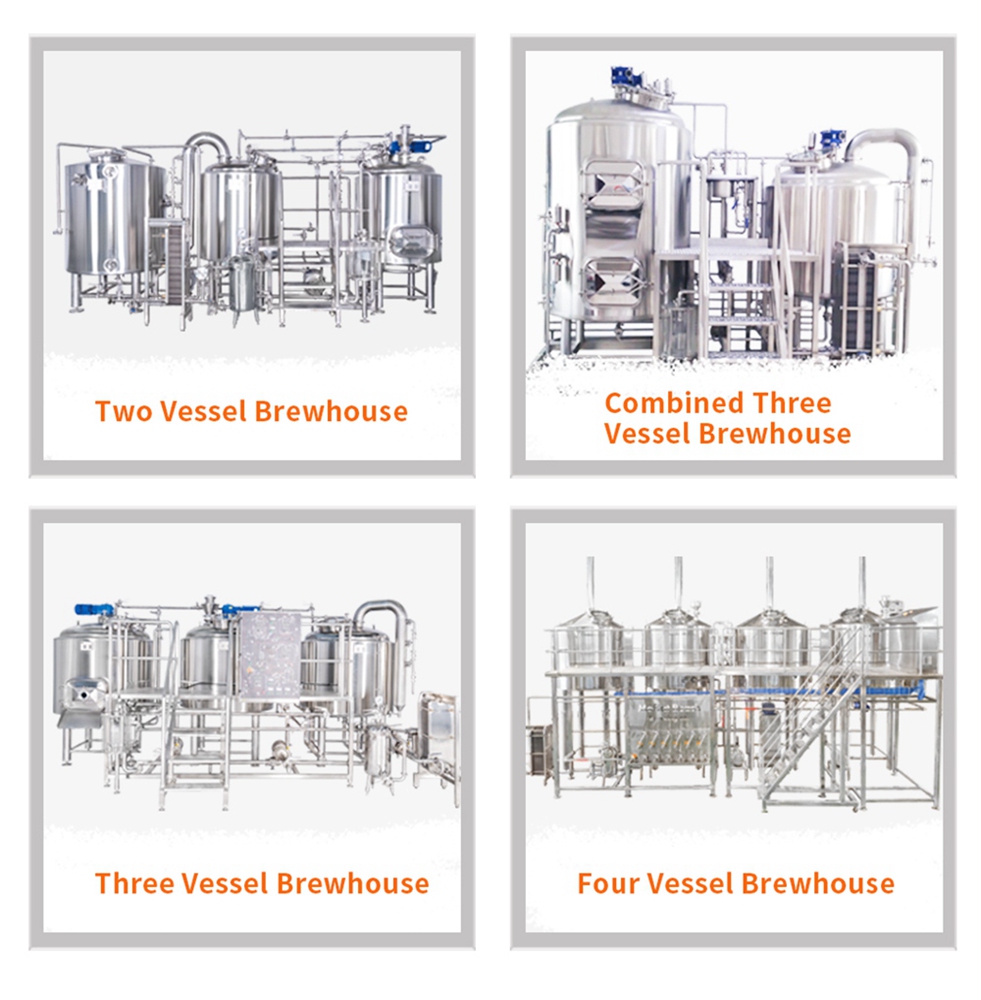

- Different configurations to meet different brewing process: 2-vessel, 3-vessel, combined 3-vessel or 4-vessel for option.

- Hot water tank to supply moderate temperature for mashing, sparing water, and cleaning water

- Cold water tank for option to cool hot wort, and recycle the heat exchanged hot water to save the brewery energy.

- Heat Exchanger: Two stages to cool the hot wort(First stage is city water, second stage is glycol water ) or one stage for cold water.

- Heating options: Electric, steam, or direct fire.

- Food-grade stainless steel 304 stainless steel Interior Shell with TH=3mm, Exterior Shell with TH=2mm. Red copper or mirror for option.

- Inner tank pickled and passivated thoroughly without dead corner.

- Welding by automatic welding machine.

- Precision temperature and flow controls for repeatable results.

- Integrated wort pump, flowmeter, and heat exchanger.

- Stainless steel platform and sanitary piping layout

- Manual or semi-automatic PLC control panel (with touch screen for option)

- 0 trade risk verified by more than 2600 brewing factories.

- Quality inspection runs through the entire production process.

- Operation humanization, low costs, high costs effective.

3.Brewhouse Configuration

|

Brewhouse Unit |

Mash/Lauter tun | 1200L (total 1500L) | Side mounted grain outdoor with grain chute |

| Laser cutting V-wire False Bottom | |||

| Kettle/Whirlpool Tun | 1200L (total1560L) | Steam heating | |

| Tangential whirlpool inlet | |||

| Sanitary leveling sight glass | |||

| Hot water tank | 1200L (total1380L) | Sanitary leveling sight glass | |

| Yeast feeder | 20L | Tri clamp aeration port with ball valve | |

| Heat exchanger | 10M2(Effective area) | Completely 304 SS Corrugated plates | |

| YUY pump | 3M3x2PCS | ABB, Sanitary SUS304, VFD control | |

| Pipe and fittings | As design | completely SS304, Work Platform is included |

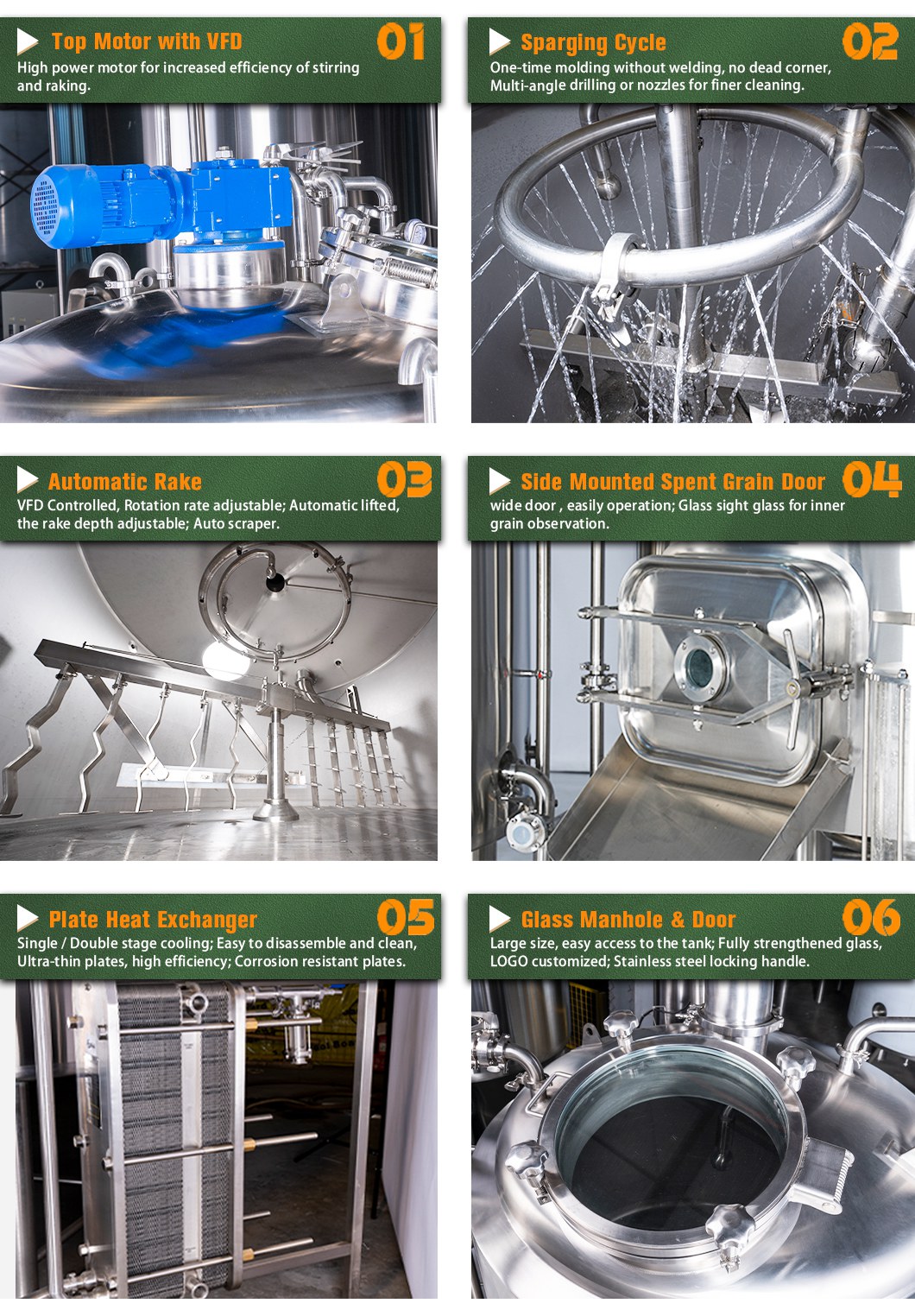

4.Brewhouse Details

5.You may be also Interested in

- Grain Malts Miller Machine

- Beer Fermenter

- Bright Beer Tank

- Glycol Chiller

- CIP Portable Pump

- Beer Filter

- Beer Keg Filler Machine

- Keg Rinser Machine

- Beer Bottling & Capping Machine

- Labeling Machine

6.Cases

7.Tiantai Company Profile

Tiantai Company, a well-recognized manufacturer of beer and beverage equipment industry based in Jinan city of China, provides complete production line and the turnkey service for breweries and beverage projects worldwide. Since 2001, Tiantai team has witnessed the rapid development of the industry with 23 years of experience. Founded in 2012 and followed by the boom of the craft beer and beverage market, Tiantai Company is committed to the research and the development of diverse brewing process, customized equipment, automatic control, and datalized management. Up to now, Tiantai Company has served over 2600 beverage factories with our equipment and solutions along with gaining good reputations.

Contact Information:

Email: [email protected]

Contact Person: Daisy Cai