1.15000L Brewhouse System Introduction

The 15000L Brewhouse System is built for large-scale commercial breweries and industrial beer production facilities that require high output, advanced automation, and exceptional production efficiency.With a daily capacity of 30,000L to 100,000L through multiple brews.This type of brewery equipment can not only meet the large-scale brewing needs of popular beers such as lager, but can also adapt to the production of various specialty craft beers to meet the unique requirements of different consumer markets.

The brewery packaging options include glass bottles, cans, kegs, and PET bottles. These are distributed to various outlets, such as supermarkets, restaurants, bars, and pubs.

It is recommended that breweries be located as close to the market as possible to reduce supply distances, simplify logistics, and guarantee the freshness of the beer.

2. Features

- Four vessel,five vessel,and six vessel configuration to meet multiple brewing per day.

- Built with steam heating to suit your energy preferences and brewing needs.

- Built entirely with high-quality SUS304 stainless steel for durability, hygiene, and long-term performance.

- Available with semi-automatic or fully automated control systems, including PLC touchscreen options

- Trusted by over 2,600 breweries worldwide, with zero trade risk and verified performance.

- Every unit undergoes strict quality inspection throughout the manufacturing process.

- Internal surfaces are pickled and passivated, ensuring a smooth, corrosion-resistant interior without dead corners

3.Brewhouse Configuration

| Brewhouse Unit | Mash tun | 15000L | Steam jacket on bottom and side Agitator inside Wort hydrator mounted top of mash tun |

| Lauter tun | 15000L | Grain rake with VFD Laser cutting V-wire False Bottom Easy clean and detachable sparging spray ring Multihole wort collect ring(optional) Anti-rinser(optional) |

|

| Kettle Tun | 15000L | Steam Jacket on bottom and side Steam vent with condensate ring for kettle stack |

|

| Whirlpool Tun | 15000L | Tangential whirlpool inlet | |

| Hot water tank | 30000L | Hot water supply and recycle |

4. Brewhouse Details

5.You may be also Interested in

- Miller

- 30,000L or 60,000LFermenter combined

- 30,000L or 60,000LBBT combined

- Beer Filter

- Keg Filling Machine

- Keg Washing Machine

- Canning Machine

- Bottling Machine

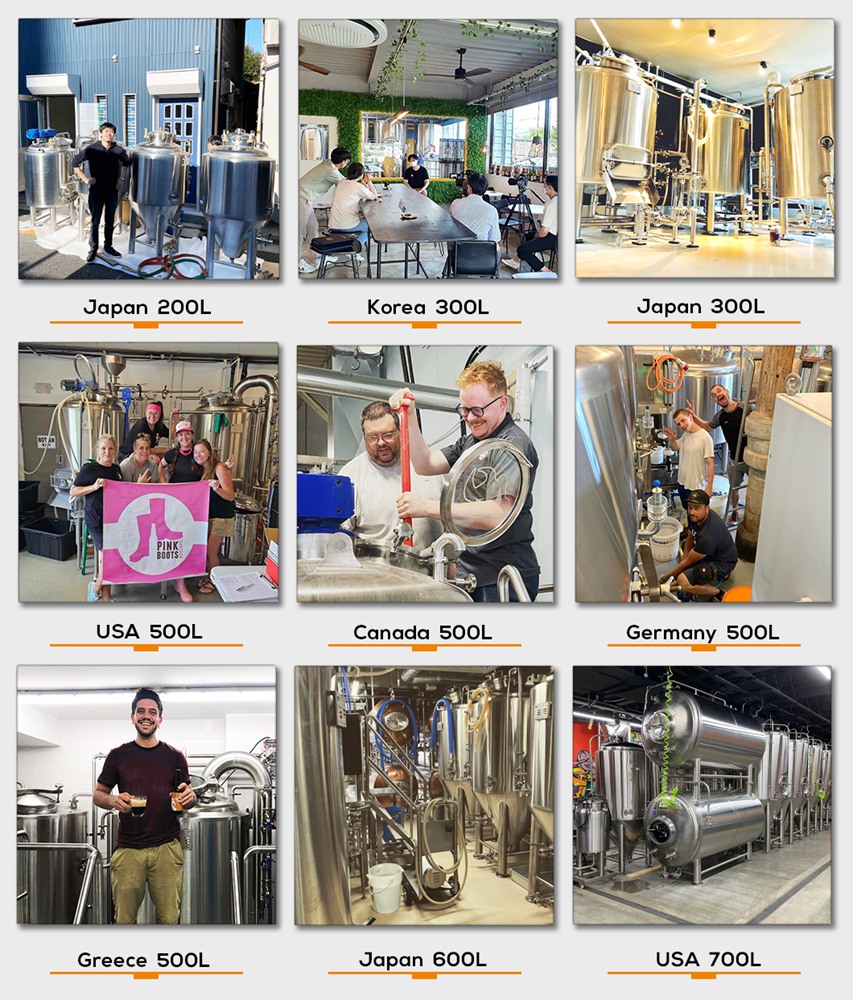

6.Cases

7.Tiantai Company Profile

Tiantai Company, a well-recognized manufacturer of beer and beverage equipment industry based in Jinan city of China, provides complete production line and the turnkey service for breweries and beverage projects worldwide. Tiantai team has witnessed the rapid development of the industry with 25 years of experience. Founded in 2012 and followed by the boom of the craft beer and beverage market, Tiantai Company is committed to the research and the development of diverse brewing process, customized equipment, automatic control, and datalized management. Up to now, Tiantai Company has served over 2600 beverage factories with our equipment and solutions along with gaining good reputations.

Contact Information:

Email: [email protected]

Contact Person: Helen Lee