1.25000L Fermentation Tank Introduction

The TIANTAI 25,000L Fermentation Tank is a large-scale, industrial-grade vessel designed to meet the high-volume production demands of commercial breweries. Engineered from premium 304/316 stainless steel with a cylindroconical structure (typically 60° cone angle), this fermenter ensures efficient yeast sedimentation, simplified yeast harvesting, and optimal beer maturation even at industrial production levels.Equipped with multi-zone glycol cooling jackets, the 25,000L fermenter provides precise temperature control, allowing breweries to produce a wide range of beer styles consistently and efficiently. Its pressure-rated construction enables both primary fermentation and secondary conditioning, while the integrated CIP (Clean-in-Place) system guarantees thorough sanitation and minimal downtime.

The TIANTAI 25,000L fermentation tank delivers robust construction, consistent performance, and efficient brewing operations, making it the ideal solution for breweries scaling up to high-capacity, industrial beer production.

2.Features

- Capacity: 25,000 Liters (working volume)

- Material: Food-grade 304/316 stainless steel with sanitary interior finish (Ra ≤0.4μm)

- Design: Cylindroconical tank with 60° cone for optimal yeast separation and harvesting

- Temperature Control: Multi-zone glycol jackets with accurate sensor monitoring

- Pressure & Safety: Pressure-rated tank with PRV, sample valve, manway, and safety fittings

- Cleaning & Maintenance: Integrated CIP spray ball and bottom drain for fast, efficient sanitation

- Applications: Ideal for industrial breweries with large-scale production of lagers, ales, and specialty beers

3. Configuration

| Function: | Fermenting for beer, kombucha, cold coffee, cider |

| Material: | SUS304 full welded; Interior TH=(C)5mm*(S)4mm,Exterior TH=2mm. |

| Interior Finish: | Sanitary 2B finish, Pickled and Passivated; (8K Mirror finish optional) |

| Exterior Finish: | Oil brushed finish(2B, 8K Mirror finish optional) |

| Welding & Polishing: | 100% TIG welding with pure argon gas shield; Interior full polished to 0.2~0.4 μm without dead corner. |

| Insulation: | TH=100mm with low thermal conductivity PU |

| Cooling: | 35% Glycol liquid -5℃; Cooling Jacket,Dimple plate on bottom and side wall, welded without over burning |

| Working Pressure: | 2bar/30psi |

| Top & Bottom: | Full polished Dished top, Conical bottom with 60° |

| Manway: | Sanitary side/top mounted oval manhole with pressured door |

| CIP : | CIP arm with four-way connection and butterfly valve; Top mounted double clamp 360° rotary CIP spraying ball and port, 1pcs |

| Mechanical safe valve PVRV: | 2bar/30psi on top (1bar/15psi available) |

| Sampling Valve: | Full sanitary sampling valve with EPDM seal |

| Pressure gauge: | Hydraulic shock standard on CIP arm (Diaphragm type for optional) |

| Discharge arm: | With butterfly valve, Removable and easy to clean |

| Thermowell : | Sanitary welded thermowell for high accuracy temperature sensor 1pcs |

| Carbonation: | Carbonation port with CO2 dissolved stone 0.22um |

| Glycol water port: | In/out port on side wall and cone, thick wall pipe thread (Top or bottom design available) |

| Legs: | 4pcs completely SUS304 legs with braces,heavy duty foot pad with up-down and slop adjustable |

| Accessories: | Complete valves, fittings and all parts, Tri clamp/DIN Union available |

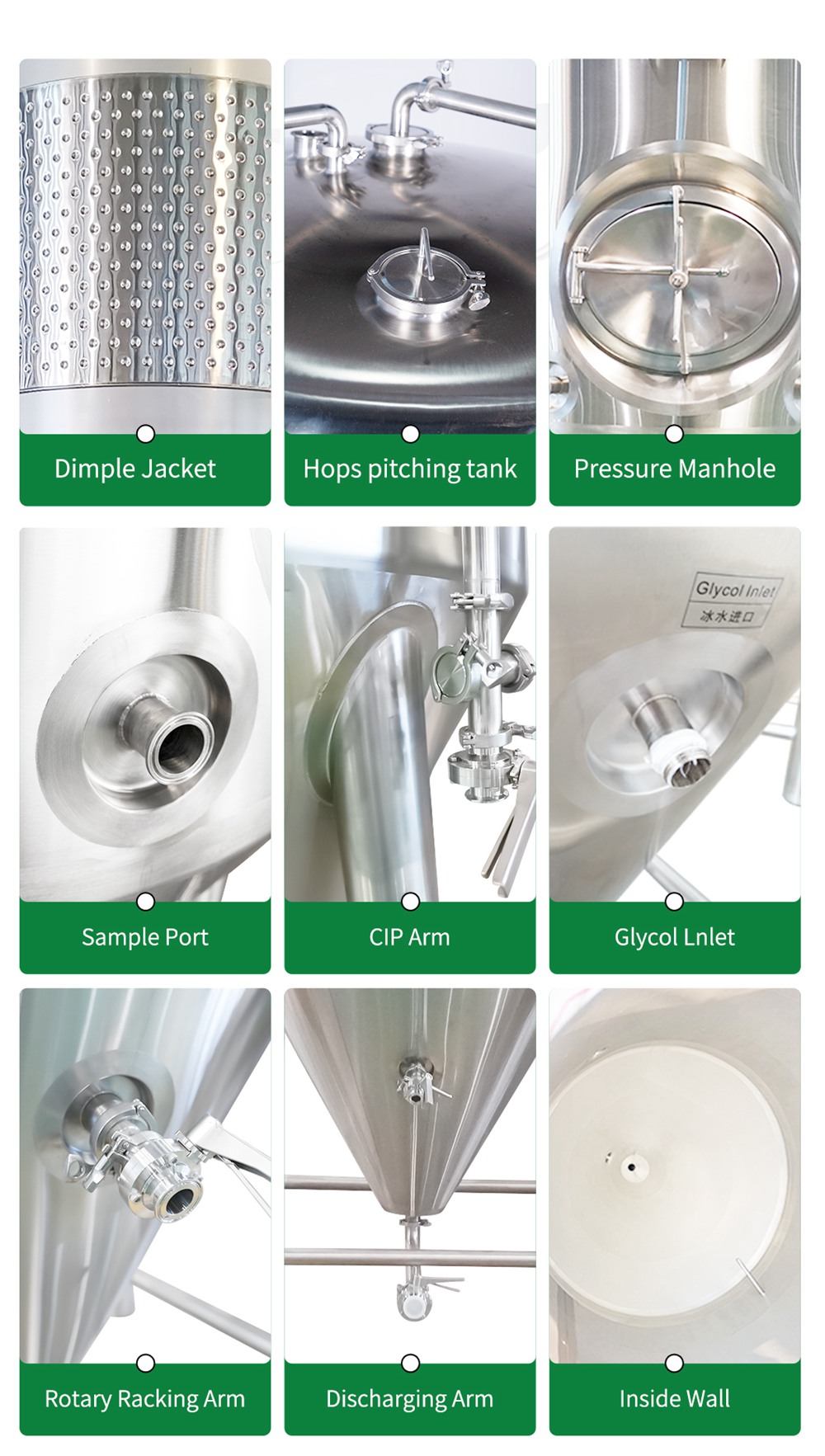

4.Fermentation Tank Details

5.You may be also Interested in

- Grain Malts Miller Machine

- Brewhouse System

- Bright tank

- Beer Filter

- Beer Keg Filler Machine

- Keg Rinser/Washer Machine

- Beer Bottling & Capping Machine

- Labeling Machine

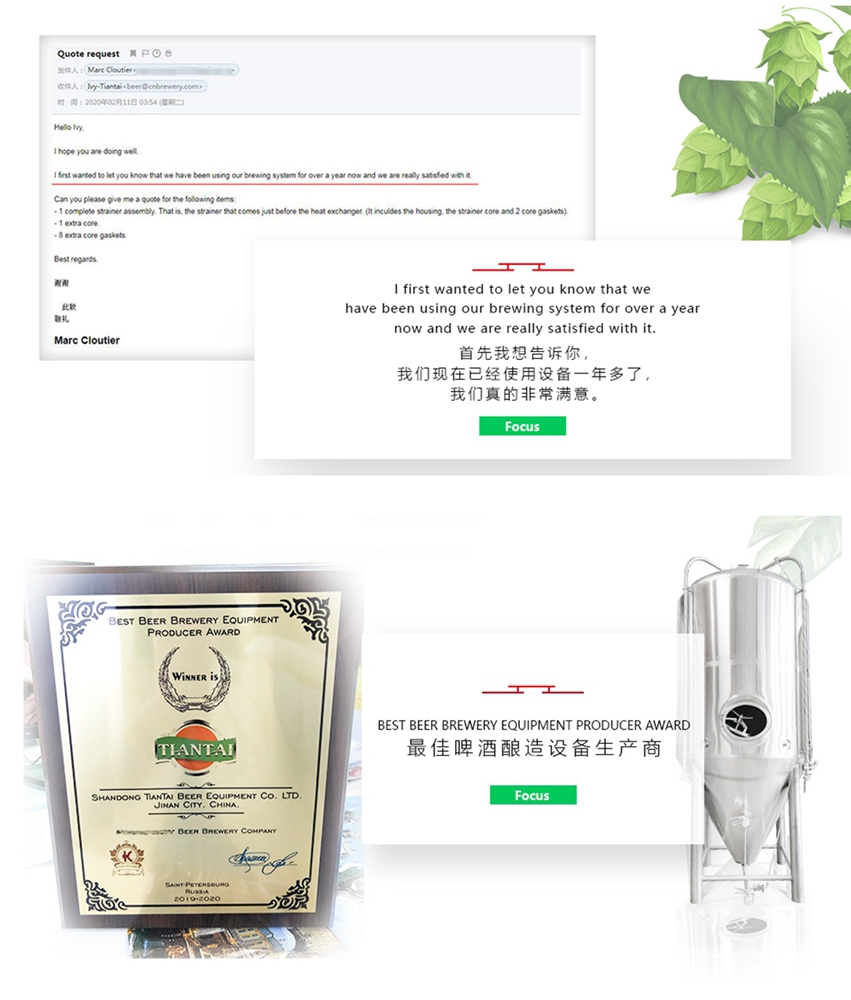

6.Cases

7.Tiantai Company Profile

Tiantai Company, a well-recognized manufacturer of beer and beverage equipment industry based in Jinan city of China, provides complete production line and the turnkey service for breweries and beverage projects worldwide. Since 2001, Tiantai team has witnessed the rapid development of the industry with 23 years of experience. Founded in 2012 and followed by the boom of the craft beer and beverage market, Tiantai Company is committed to the research and the development of diverse brewing process, customized equipment, automatic control, and datalized management. Up to now, Tiantai Company has served over 2600 beverage factories with our equipment and solutions along with gaining good reputations.

Contact Information:

Email: [email protected]

Contact Person: Daisy Cai