Our 300L and 3000L Secondary Yeast Propagation Tanks represent a significant advancement in brewery biotechnology, offering professional brewers a sophisticated and reliable solution for large-scale yeast cultivation. These tanks are meticulously engineered to support the entire yeast propagation process, enabling breweries to safely and efficiently generate substantial volumes of highly viable, healthy yeast cultures. Whether you’re operating a specialized craft brewery or managing a large-scale production facility, this advanced propagation system guarantees consistent yeast vitality and optimal fermentation performance, ultimately contributing to superior product quality and operational efficiency.

The foundation of these propagation tanks begins with their premium construction materials. Manufactured from food-grade SUS 304 Stainless Steel, they provide exceptional corrosion resistance, impeccable hygiene standards, and long-term structural durability. This material selection ensures compatibility with rigorous brewing environments while maintaining the purity of yeast cultures throughout the propagation cycle. The manufacturing process incorporates 100% TIG Argon Gas Welding for all joints and connections, resulting in perfectly smooth, polished welds that eliminate any potential dead corners or bacterial harborage points. This fully sanitary design philosophy extends throughout the entire system, creating an optimal environment for pure yeast culture development.

Designed specifically for secondary yeast propagation, these tanks facilitate a systematic, two-stage cultivation process that maximizes yeast activity and population density before pitching into primary fermentation vessels. The temperature control system represents a cornerstone of the propagation process, featuring advanced dimple jacket technology that enables precise thermal regulation through glycol circulation. This sophisticated temperature management ensures the maintenance of ideal conditions for yeast metabolism and reproduction throughout all growth phases. Complementing this thermal control, the integrated aeration system incorporates a high-efficiency diffusion stone and sanitary valves that allow brewers to precisely manage dissolved oxygen levels, stimulating healthy yeast reproduction and enhancing overall culture vitality.

Understanding the critical importance of cleanliness in yeast handling, these propagation tanks are fully equipped with comprehensive Clean-in-Place (CIP) capabilities. The system includes a strategically positioned 360-degree rotary spray ball that ensures complete interior surface coverage during cleaning cycles, along with dedicated CIP ports that facilitate automated sanitation procedures. This design eliminates the need for manual cleaning while guaranteeing thorough sterilization between batches. Available in both 300L and 3000L configurations, these propagation tanks accommodate various production scales while maintaining identical performance standards and quality assurance. The thoughtful integration of these advanced features establishes a new benchmark in yeast propagation technology, providing brewers with unprecedented control over one of the most critical elements in the brewing process.

| Application | Secondary Yeast Propagation | Secondary Yeast Propagation |

| Accessories | Aeration Stone, Pressure Gauge, Sampling Valve, Sight Glass, CIP Arm, Thermometer | Aeration Stone, Pressure Gauge, Sampling Valve, Sight Glass, CIP Arm, Thermometer |

| Temperature Control | Dimple Jacket for Glycol Cooling | Dimple Jacket for Glycol Cooling |

| Pressure Rating | ≤ 2 bar (Adjustable) | ≤ 2 bar (Adjustable) |

| Surface Finish | Internal Ra ≤ 0.4μm Mirror Polish | Internal Ra ≤ 0.4μm Mirror Polish |

| Welding Method | 100% TIG Argon Arc Welding | 100% TIG Argon Arc Welding |

| Material | SUS 304 Food-Grade Stainless Steel | SUS 304 Food-Grade Stainless Steel |

| Volume | 300 Liters (Net) | 3000 Liters (Net) |

.jpg)

.jpg)

.jpg)

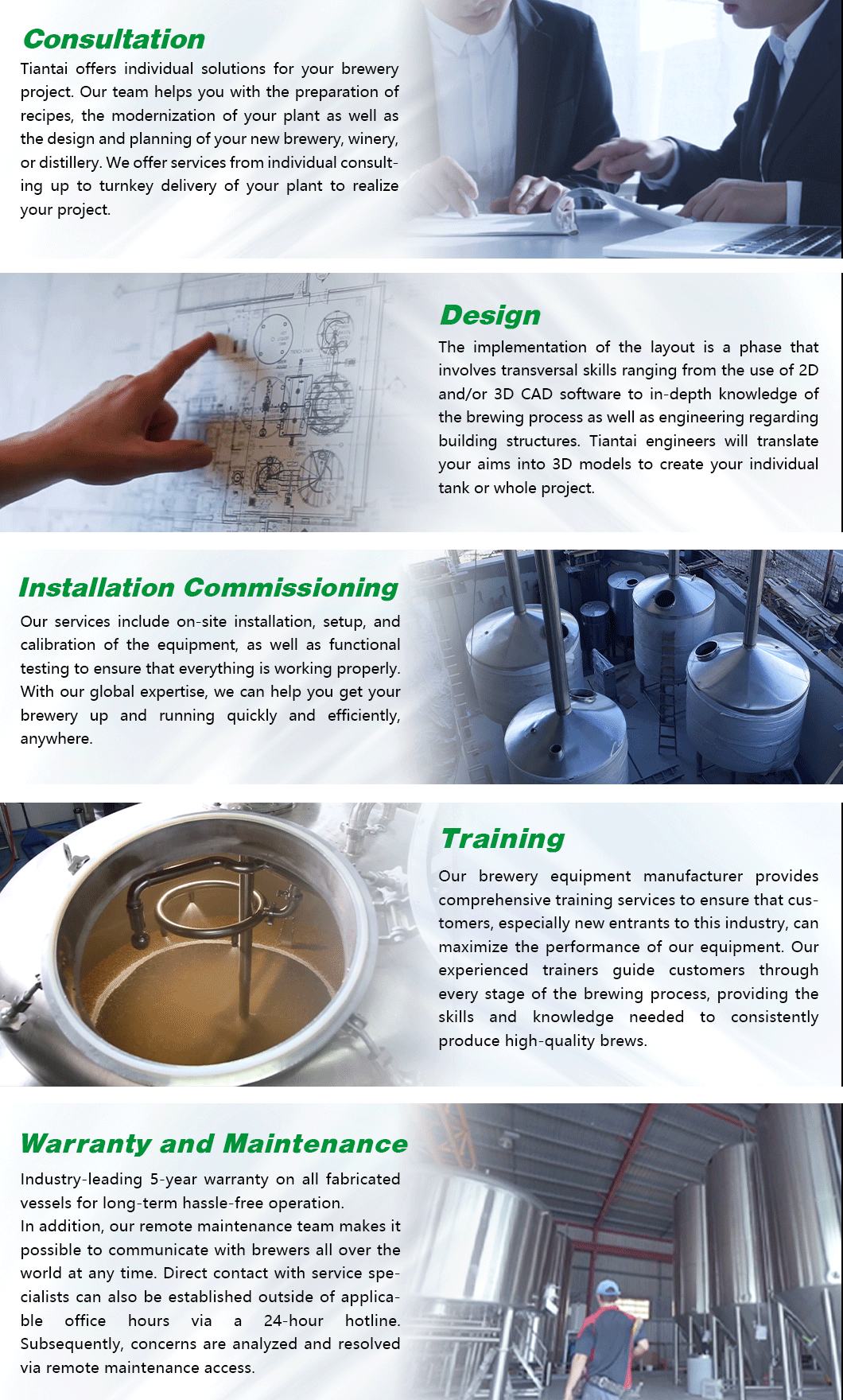

TIANTAI turnkey brewery plants offer innovative solutions and cutting-edge technology to help you achieve your brewing dreams. With Tiantai you can trust that your brewery project will be in expert hands from start to finish. As a general contractor, Tiantai supplies turnkey solutions for the entire brewery. We manufacture precisely matched brewery systems developed according to energy and economic aspects. With our decades-long experience in integrative systems construction, we have successfully completed a multitude of turnkey projects all around the globe.

Learn more how Tiantai beer equipment company to not only produce the best quality brewery equipment for flavor-rich beers, but also help them to optimize the configuration, maximize process uptime and reduce beer loss when they brewing, PLEASE DON’T HESITATE TO CONTACT WITH US!

Hubert

Email: [email protected]