1.300L Brewhouse System Introduction

Tiantai’s 300L Brewhouse System offers a space-efficient, high-performance brewing solution tailored for small-batch production. Ideal for craft breweries, pilot batches, R&D environments, recipe trials, and brewpubs, this system delivers reliability and versatility in a compact package.

Engineered with professional-grade features and intuitive operation, the 300L setup allows brewers to maintain consistency and quality across every batch. Whether you’re testing new formulations, crafting limited-edition brews, or conducting staff training, this system provides the control and repeatability you need.

2.Features

Available in two-vessel (Mash/Lauter + Kettle/Whirlpool) or three-vessel configurations for process flexibility

Electric or steam heating options to suit your energy preferences and infrastructure

Constructed with premium SUS304 stainless steel for durability and hygiene

Precision control panel with integrated temperature sensors and optional automation for consistent brewing

Sight glass included for easy lautering monitoring

Equipped with sanitary valves and tri-clamp connections for secure and hygienic operation

Compact design optimized for breweries with space constraints

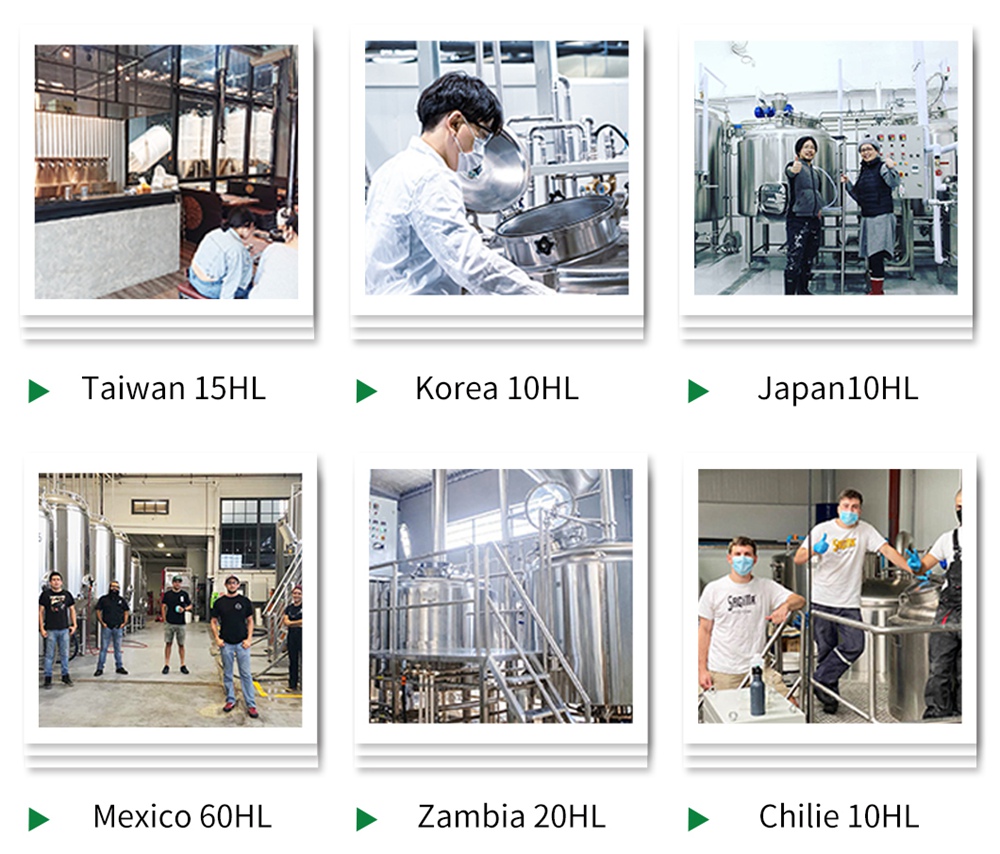

Zero trade risk — trusted by over 2,600 breweries worldwide

Strict quality control maintained throughout the entire manufacturing process

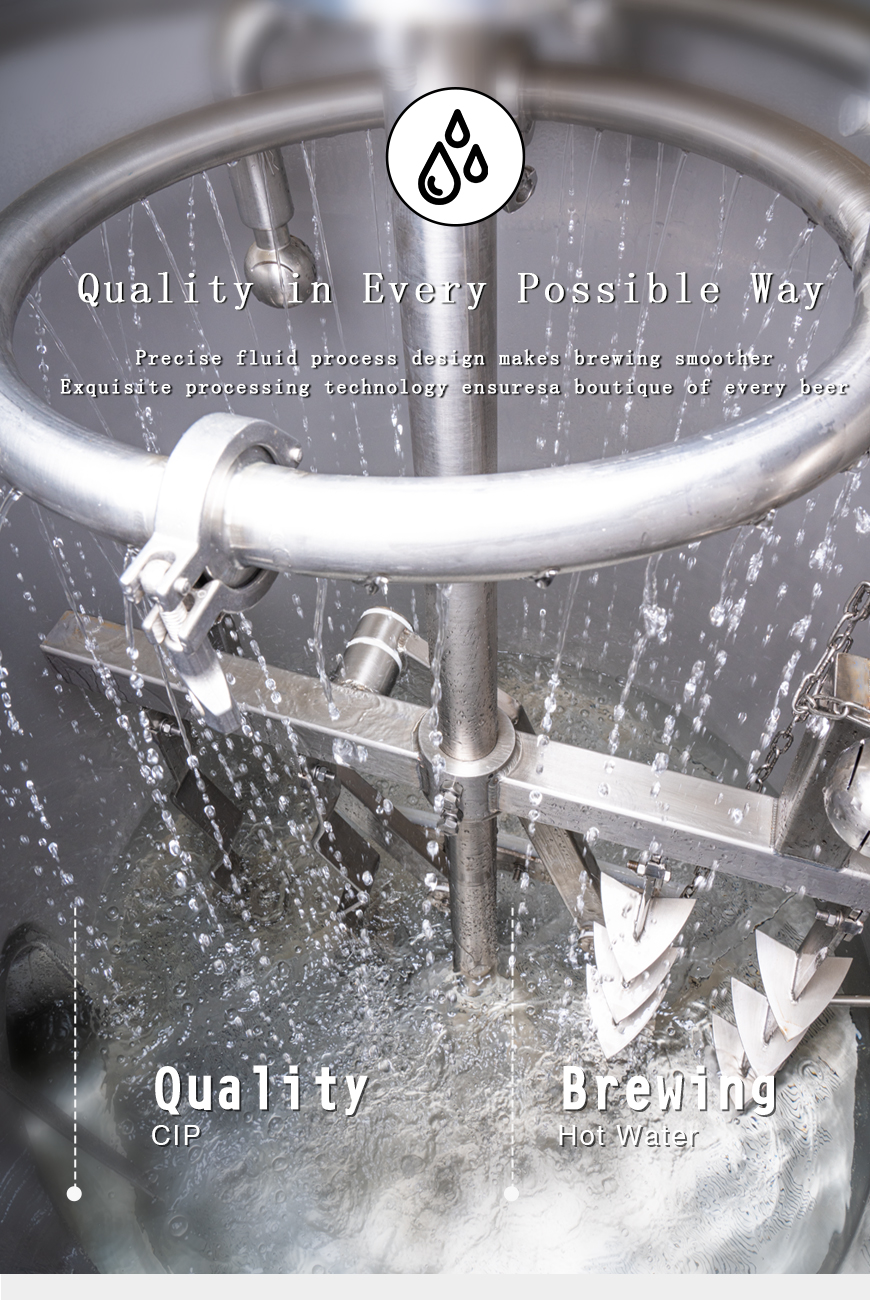

Thorough pickling and passivation of internal surfaces to eliminate dead zones and ensure cleanability

High-precision welding performed using automated welding systems for long-term reliability

3.Brewhouse Configuration

| Brewhouse Unit | Mash/Lauter tun | 300L (total 375L) | Side mounted grain outdoor with grain chute |

| Laser cutting V-wire False Bottom | |||

| Kettle/Whirlpool Tun | 300L (total 420L) | Electric heating; Power: 9kw | |

| Tangential whirlpool inlet | |||

| Sanitary leveling sight glass | |||

| Yeast feeder | 10L | Tri clamp aeration port with ball valve | |

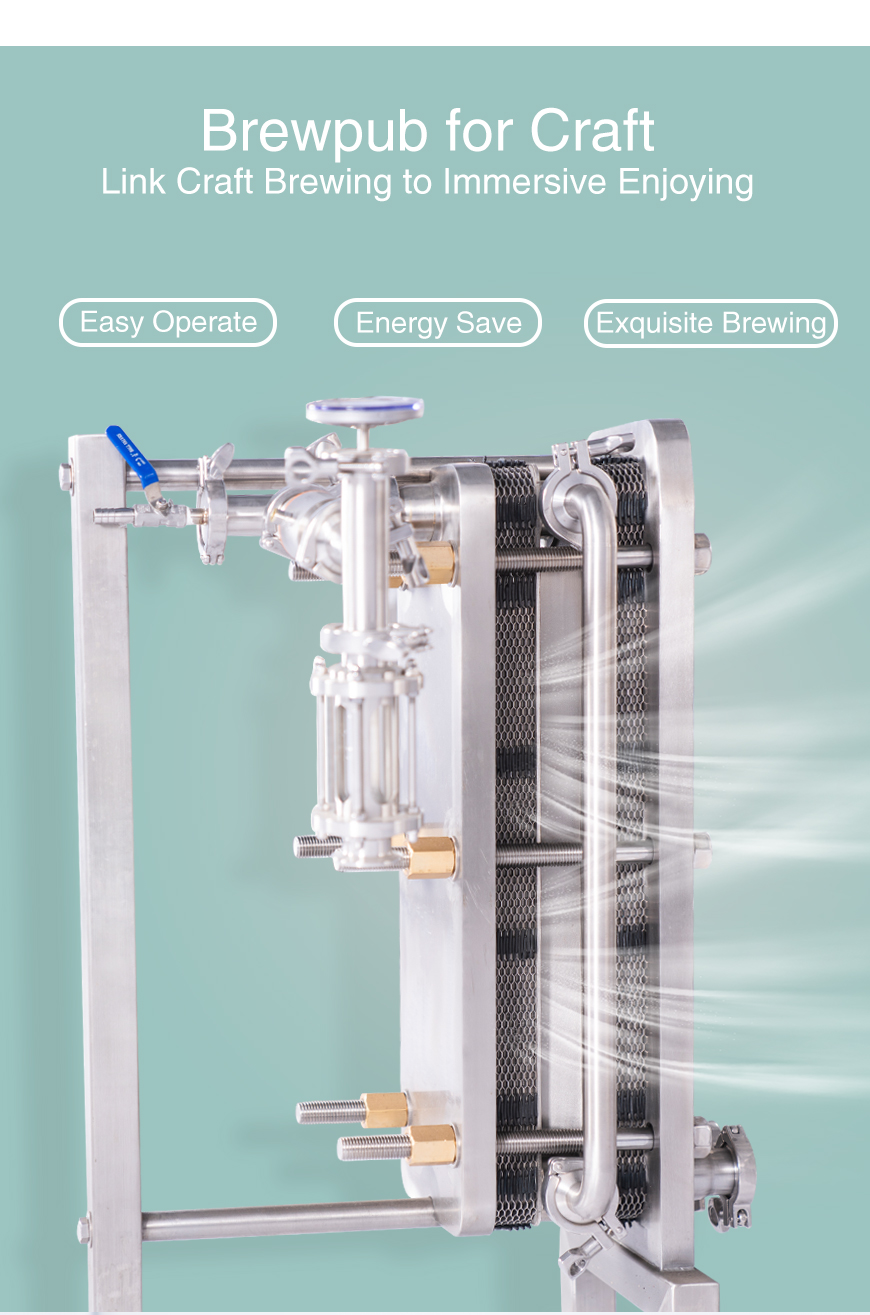

| Heat exchanger | 4M2(Effective area) | Completely 304 SS Corrugated plates | |

| Centrifugal pump | 3M3 | ABB, Sanitary SUS304, VFD control | |

| Pipe and fittings | As design | completely SS304 |

4.Brewhouse Details

5.You may be also Interested in

- Milling

- Fermenter

- Bright tank

- Beer Filter

- Beer Filling Machine

6.Cases

7.Tiantai Company Profile

Tiantai Company is a recognized leader in the beer and beverage equipment industry, headquartered in Jinan, China. We specialize in providing complete production lines and turnkey solutions for breweries and beverage projects around the world.With 23 years of experience in the field—originating in 2001 and officially established in 2012—Tiantai has grown alongside the global rise of the craft beer and beverage market. We are dedicated to continuous innovation in brewing processes, customized equipment design, automation, and data-driven management.To date, Tiantai has proudly served more than 2,600 beverage factories worldwide, earning a solid reputation for quality, reliability, and customer-focused service.

If you are interested in a brewery, I believe Tiantai will give you the best solution and a flexible and dynamic brewery plan.

Contact Hubert for a free proposal for your dream now.

Email: [email protected]