—Product Introduction

Our 500L and 5000L Secondary Yeast Propagation Tanks are engineered for professional breweries to reliably cultivate healthy yeast at scale. Perfect for craft beer producers and expanding operations alike, these tanks help maintain strong yeast vitality and achieve peak fermentation performance.

—Key Features

High-Grade Material:

Constructed with food-grade SUS 304 Stainless Steel, providing superior corrosion resistance, hygiene, and structural durability.

Sanitary Welding:

All joints are TIG-welded with argon gas protection, resulting in smooth, crevice-free seams and a completely hygienic interior.

Dual-Stage Propagation:

Designed specifically for secondary yeast propagation, this system maximizes yeast activity before it is transferred to the main fermentation tanks.

Precise Temperature Control:

Fitted with dimple jacket cooling for accurate glycol-based temperature management, creating the perfect conditions for yeast development.

Integrated Aeration:

Features a built-in aeration stone and sanitary valves to effectively regulate dissolved oxygen and promote yeast growth.

CIP Compatibility:

Includes a 360° rotary spray ball and dedicated CIP port for effortless and thorough internal cleaning.

Available Capacities:

500L Yeast Propagation Tank | 5000L Yeast Propagation Tank

| Application | Secondary Yeast Propagation | Secondary Yeast Propagation |

| Accessories | Aeration Stone, Pressure Gauge, Sampling Valve, Sight Glass, CIP Arm, Thermometer | Aeration Stone, Pressure Gauge, Sampling Valve, Sight Glass, CIP Arm, Thermometer |

| Temperature Control | Dimple Jacket for Glycol Cooling | Dimple Jacket for Glycol Cooling |

| Pressure Rating | ≤ 2 bar (Adjustable) | ≤ 2 bar (Adjustable) |

| Surface Finish | Internal Ra ≤ 0.4μm Mirror Polish | Internal Ra ≤ 0.4μm Mirror Polish |

| Welding Method | 100% TIG Argon Arc Welding | 100% TIG Argon Arc Welding |

| Material | SUS 304 Food-Grade Stainless Steel | SUS 304 Food-Grade Stainless Steel |

| Volume | 500 Liters (Net) | 5000 Liters (Net) |

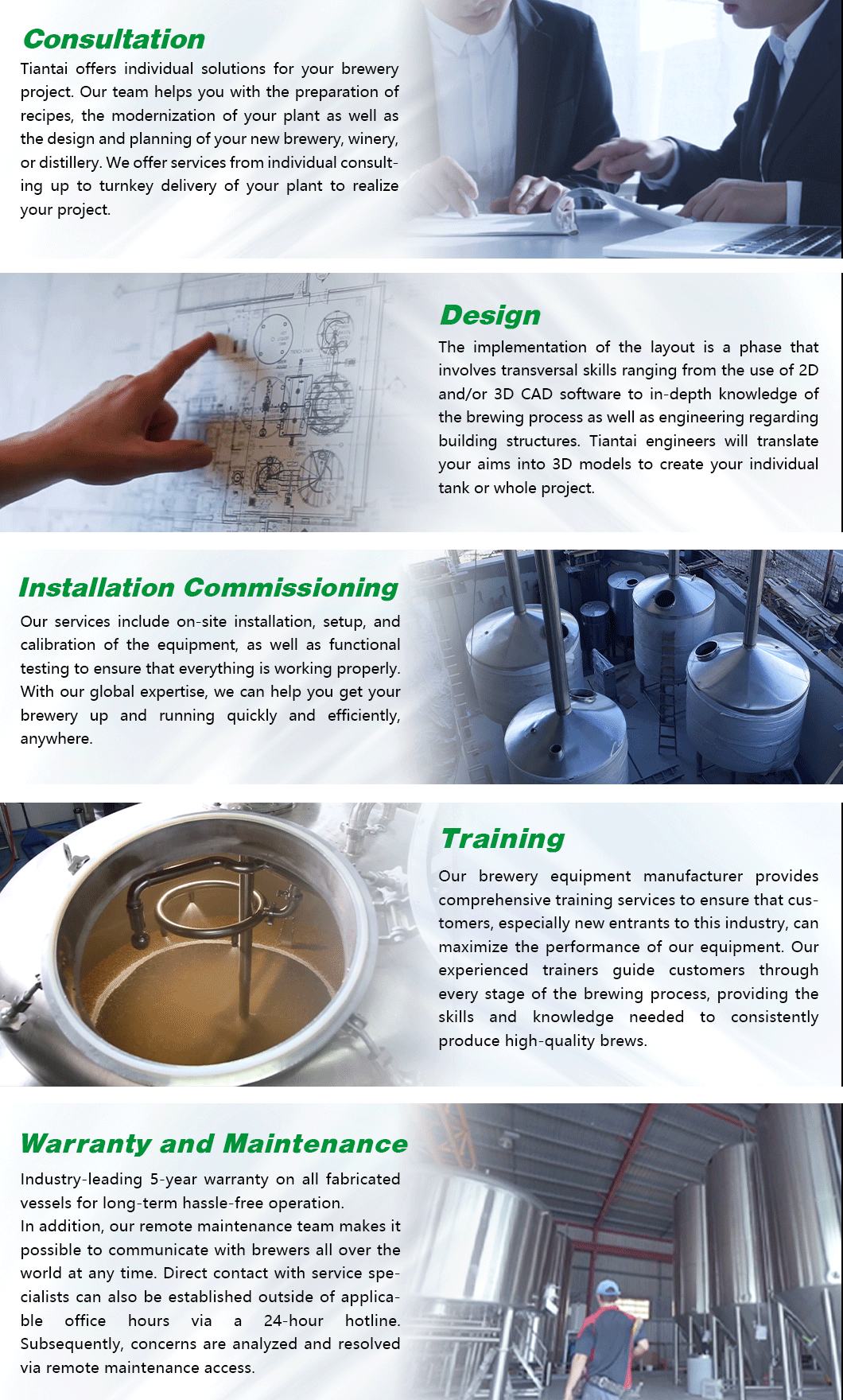

TIANTAI turnkey brewery plants offer innovative solutions and cutting-edge technology to help you achieve your brewing dreams. With Tiantai you can trust that your brewery project will be in expert hands from start to finish. As a general contractor, Tiantai supplies turnkey solutions for the entire brewery. We manufacture precisely matched brewery systems developed according to energy and economic aspects. With our decades-long experience in integrative systems construction, we have successfully completed a multitude of turnkey projects all around the globe.

Learn more how Tiantai beer equipment company to not only produce the best quality brewery equipment for flavor-rich beers, but also help them to optimize the configuration, maximize process uptime and reduce beer loss when they brewing, PLEASE DON’T HESITATE TO CONTACT WITH US!

Hubert

Email: [email protected]