500L/Hr Disc Stack Centrifuge — For Crystal-Clear Beer in Every Batch

In the world of craft beer, flavor and clarity should never be a compromise. Yeast management, beer stability, and flavor purity are key to determining whether a beer can stand out in a competitive market. The Tiantai 500L/Hr Disc Stack Centrifuge, specially designed for breweries, is your ultimate solution to these challenges. It is more than just a piece of equipment—it is a silent and reliable member of your brewing team, dedicated to efficiently separating yeast, cold trub, and various fine impurities after fermentation and before packaging. This ensures exceptional clarity, more stable flavor profiles, and a longer shelf life for every batch of beer.

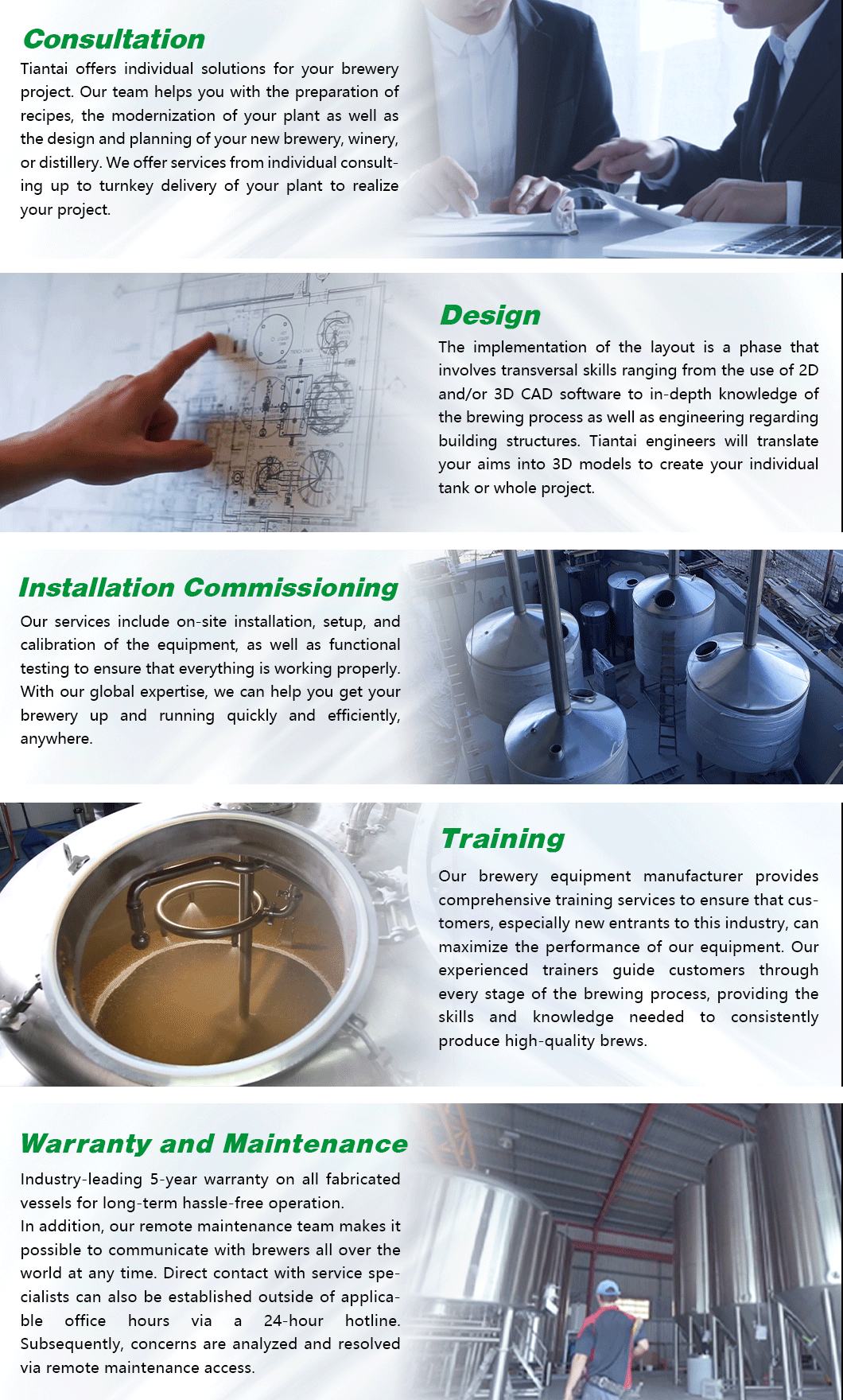

Why Is Professional Centrifugation Essential in Brewing?

-

Enhances Beer Quality: Efficiently removes residual yeast and cold haze particles after fermentation, eliminating the risk of refermentation and achieving a crystal-clear beer appearance that makes the beer’s color more appealing.

-

Locks in Consistent Flavor: By precisely controlling the separation process, it effectively preserves the delicate flavor compounds in the beer while removing impurities that could cause off-flavors, ensuring the carefully crafted beer taste remains consistent from the first keg to the last bottle.

-

Streamlines Production: Compared to traditional filtration or settling methods, centrifugation significantly shortens the cycle from fermentation to packaging, increasing equipment utilization and enabling you to respond more quickly to market demands.

Core Advantages Tailored for Brewing Processes

-

Gentle yet Efficient, Flavor-Protecting

Our centrifuge features a unique fluid design, ensuring the beer is treated with the utmost care during separation. This minimizes oxygen exposure and preserves the beer’s valuable aromas and mouthfeel. Its high-efficiency separation capability handles a wide range of beer types, from ales to lagers. -

Full Food-Grade Stainless Steel Construction & CIP Design

The equipment is entirely constructed from SUS 304 stainless steel, compliant with the highest food hygiene standards, ensuring no sanitary dead ends. Coupled with a complete CIP (Clean-in-Place) system, it allows for rapid and thorough cleaning and sanitization between batches, fully meeting the stringent hygiene requirements of beer production and preventing cross-contamination. -

Precise Yeast Recovery for Added Value

For processes requiring yeast reuse, this centrifuge can precisely control the concentration and collection of yeast, helping you obtain highly active, high-quality yeast slurry for the next fermentation cycle. This reduces production costs and enhances economic benefits. -

Compact and Energy-Efficient, Designed for Craft Breweries

The 500L/hour throughput is specifically designed for small to medium-scale batch production. Its compact footprint allows for easy integration into existing production lines, while its optimized energy consumption design ensures operating costs are significantly lower than traditional methods, making advanced technology accessible for craft breweries without financial strain.

.jpg)

| Function:Yeast separator for more clear beer |

| Model:BRSX10-D |

| Capacity: 500L/hr |

| Blocks Design: Main Separator, Piping, Control Cabinet, Bottom Bracket |

| Weight:400kg |

| Dimension: 1015×1200×1400mm |

| Blocks Composion I: Main Separator |

| Main Body:Build in Carbon and Covered by 304 stainless steel |

| Material:304 stainless steel for all connection parts |

| Drum Diameter:300mm |

| Separate Factor: >12900 |

| Motor Power:7.5Kw (WANNAN/ABB/WEG etc) |

| Drainage Time: 0.01-9.99s |

| Drainage Intervals:1-240min |

| Start Time: 8-10min |

| Stop Time (Non Brake):<40min |

| Inlet Pressure: 0-0.1MPa |

| Outlet Pressure: 0-0.3MPa |

| Working Water Pressure: 0.2MPa – 0.45MPa |

| Oxygenation:>10ppb |

| Blocks Composion II: Piping Line |

| All sanitary 304 stainless steel pipe |

| Pneumatic butterfly valve (Donjoy/LYSF etc) |

| Flow meter included Konggang (IFM/E+H for special request) |

| Adjustable Valve for flow (Donjoy) |

| Sanitary sample valve |

| Diaphram pump for yeast drainage (Bianfeng) |

| High/Low liquid level sensor (IFM) |

| Sanitary soft pipe |

| Blocks Composion III: Electric Control Cabinet |

| VFD control for pump (KUMART/DELTA/ABB etc) |

| Stainless steel control cabinet |

| Wordwide brand electrical parts ABB/Schneide/FUJI/LS |

| Blocks Composion IV: Bottom Bracket |

| All 304 stainless steel |

.jpg)

.jpg)

Choosing the Tiantai Centrifuge means choosing uncompromising quality. Let our reliable technology safeguard every drop of beer you’ve poured your heart into, helping you stabilize quality, improve efficiency, and go further on your craft brewing journey.

Tiantai: Your Trusted Partner in Turnkey Brewery Solutions.

Hubert

Email: [email protected]