A -5℃ air-cooled industrial chiller for a brewery cooling system is a key piece of equipment used to maintain precise low temperatures for various stages of the brewing process. It is designed to cool a glycol-water mixture down to -5°C, which is then circulated to control the temperature of fermentation tanks, bright beer tanks, and during wort cooling or cold crashing.

How It Works in a Brewery Setup

Chiller cools glycol to -5°C.

The glycol is pumped through insulated pipes to the cooling jackets of:

Fermentation tanks – to control yeast activity.

Bright beer tanks – to keep beer clear and stable.

Heat exchangers – to rapidly cool wort after boiling.

Glycol returns to the chiller, where it’s re-cooled and recirculated.

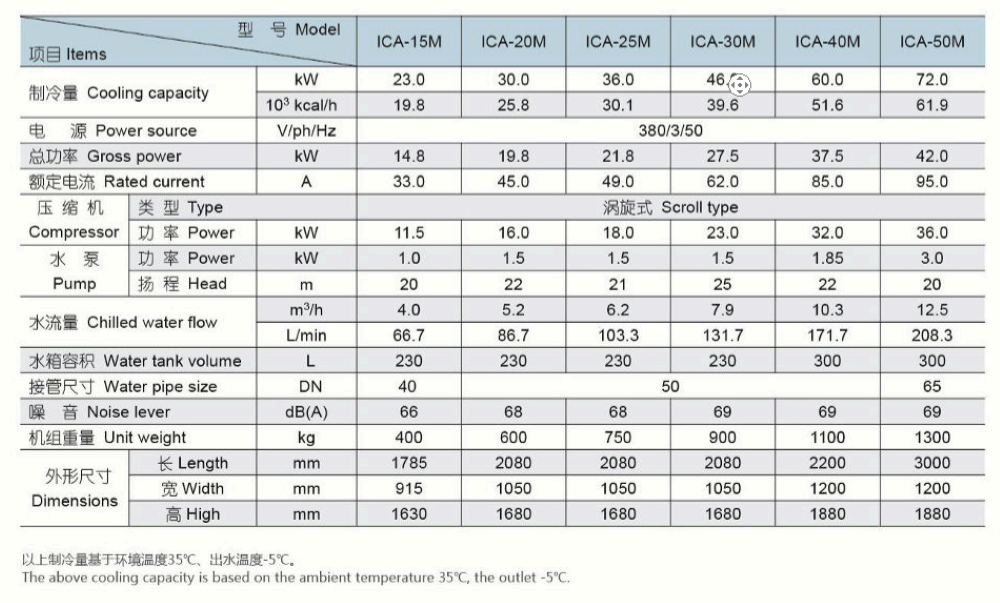

Specification of Glycol Chiller

Advantages to ensure his quality and efficiency

♦V shape top condensor. It is on top. So it has a good Thermal Dissipation.

♦A lot of protecting controls: Protector for pressure, overload, anti-freeze, delay, over-temperature, flow.This will protect chiller from damaging.

♦USA brand copper welding bar: this is the most important.

It need enough silver inside. If the silver quantity is not enough, the welding is easily to have problem and then cause the leaking. The copping welding bar they use is imported from USA.

It is USA Harris brand.

♦There is gas-liquid separator. This will protect compressor to over load.

The basement,frame and cover are much stronger. They are thicker. This will make the chiller safe when transport.

Why -5°C Is Important

A glycol solution (usually 30–40% glycol) doesn’t freeze at -5°C.

Provides faster and more effective heat transfer than water alone.

Supports cold crashing—a process to clarify beer by rapidly cooling it near freezing.

Benefits for Breweries

| Feature | Benefit |

| Low-temp (-5°C) | Enables cold crashing and fast chilling |

| Air-cooled design | No water tower needed, simple maintenance |

| Stable glycol temp | Precise control of fermentation temperatures |

| Industrial-grade | Designed for continuous use, durable in harsh environments |

Example Specs for Brewery Use

Cooling capacity: 5 HP to 50+ HP (depends on brewery size).

Temperature range: -5°C to +15°C.

Compressor: Scroll or screw type.

Circulation pump: For glycol loop.

Glycol tank: Optional, but common in brewery setups.

TIANTAI Beer Equipment Co., Ltd. is a leading manufacturer of turnkey brewing systems based in China. With over 20 years of experience, TIANTAI specializes in the design, production, and installation of high-quality craft beer, kombucha, and beverage production equipment, serving clients in over 80 countries worldwide.

Our product range includes everything from brew houses, fermentation tanks, and bright beer tanks to automated CIP systems, kegging lines, and chillers, tailored to meet the needs of both small craft breweries and large-scale commercial producers.

What sets TIANTAI apart is our focus on customization, energy efficiency, and reliable after-sales support. Whether you’re launching a new brewing project or expanding an existing one, TIANTAI offers full project solutions, from equipment design to factory layout planning, installation, and training.

Edited By Daisy Cai

[email protected]