1.6000L Bright Beer Tank Introduction

The 6000L Beer Bright Tank—also referred to as a BBT, brite tank, or storage tank—is commonly used for beer maturation, carbonation, conditioning, serving, and holding filtered beer before packaging.Purpose-built for commercial brewing operations, this tank features a dished top and bottom for structural integrity, as well as a high-efficiency cooling jacket to ensure precise temperature control during the conditioning phase. A 360-degree rotating CIP (Clean-in-Place) spray ball is installed at the top, integrated with the brewery’s CIP system, providing complete internal cleaning coverage and upholding strict hygiene and safety standards throughout the brewing process.

2.Features

Made of Stainless steel 304/316L, TIG welded by automatic welding machine.

Interior polished to 0.2-0.4 μm to ensure no dead corner for bacteria and full sanitary.

Triangle-Arranged holes on glycol jacket for higher cooling efficiency.

Dished top and bottom for CO2 pressured

Cooled by jackets on side wall, temperature auto con-trolled

Carbonation stone and fittings for CO2 evenly dissolved

Pressure adjustable, suitable for various liquid

All gaskets made of EPDM which have more durable use time.

Completely SUS304 legs with strengthening braces to prevent tank deformation.

Heavy duty foot pads with adjustable ability, apply to uneven or slope ground.

Design comply with requirements of GB/PED/ASME

Stackable design available for saving area

Copper cladding or various colors painting is available

3.Brite Tank Configuration

| Function: | Beer maturation/conditioning/serving/filtered beer receiving |

| Interior Shell: | SUS304 full welded; TH=3mm |

| Exterior Shell: | SUS304 full welded; TH=2mm |

| Welding | 100% TIG welding with pure argon gas shield |

| Interior Finish: | Sanitary 2B finish, Pickled and Passivated;

(8K Mirror finish optional) |

| Exterior Finish: | Oil brushed finish(2B, 8K Mirror finish optional) |

| Polishing | Interior full polished to 0.2~0.4 μm without dead corner |

| Insulation: | TH=80mm with low thermal conductivity PU |

| Cooling: | 35% Glycol liquid -5℃ |

| Cooling Jacket: | Dimple plate on bottom and side wall, welded without over burning |

| Jacket test | by water and gas, 5bar/75psi for 1hour, 3.5bar/52psi for 48 hours |

| Jacket Working Pressure: | < 2bar/30psi |

| Tank leakage test | by water and gas, 4bar/60psi for 1hour, 2.5bar/37.5psi for 48 hours |

| Tank Working Pressure: | 2bar/30psi |

| Dished Top: | Dished top full polished |

| Dished bottom: | Dished bottom full polished |

| Manway: | Sanitary side/top mounted oval manhole with pressured door |

| CIP Ball: | Top mounted double clamp 360° rotary CIP spraying ball and port, 1pcs |

| CIP arm: | with four-way connection and butterfly valve |

| Mechanical safe valve PVRV: | 2bar/30psi on top (1bar/15psi available) |

| Sampling Valve: | Full sanitary sampling valve with EPDM seal |

| Hydraulic shock pressure gauge: | on CIP arm (Diaphragm type for optional) |

| Discharge arm: | With butterfly valve, Removable and easy to clean |

| Thermowell : | Sanitary welded thermowell for high accuracy temperature sensor 1pcs |

| Carbonation: | Carbonation port with CO2 dissolved stone 0.22um |

| Glycol water port: | In/out port on side wall and cone,

Thick wall pipe thread (Top or bottom design available) |

| Legs: | 4pcs completely SUS304 legs with braces,

heavy duty foot pad with up-down and slop adjustable |

| Accessories: | Complete valves, fittings and all parts, Tri clamp/DIN Union available |

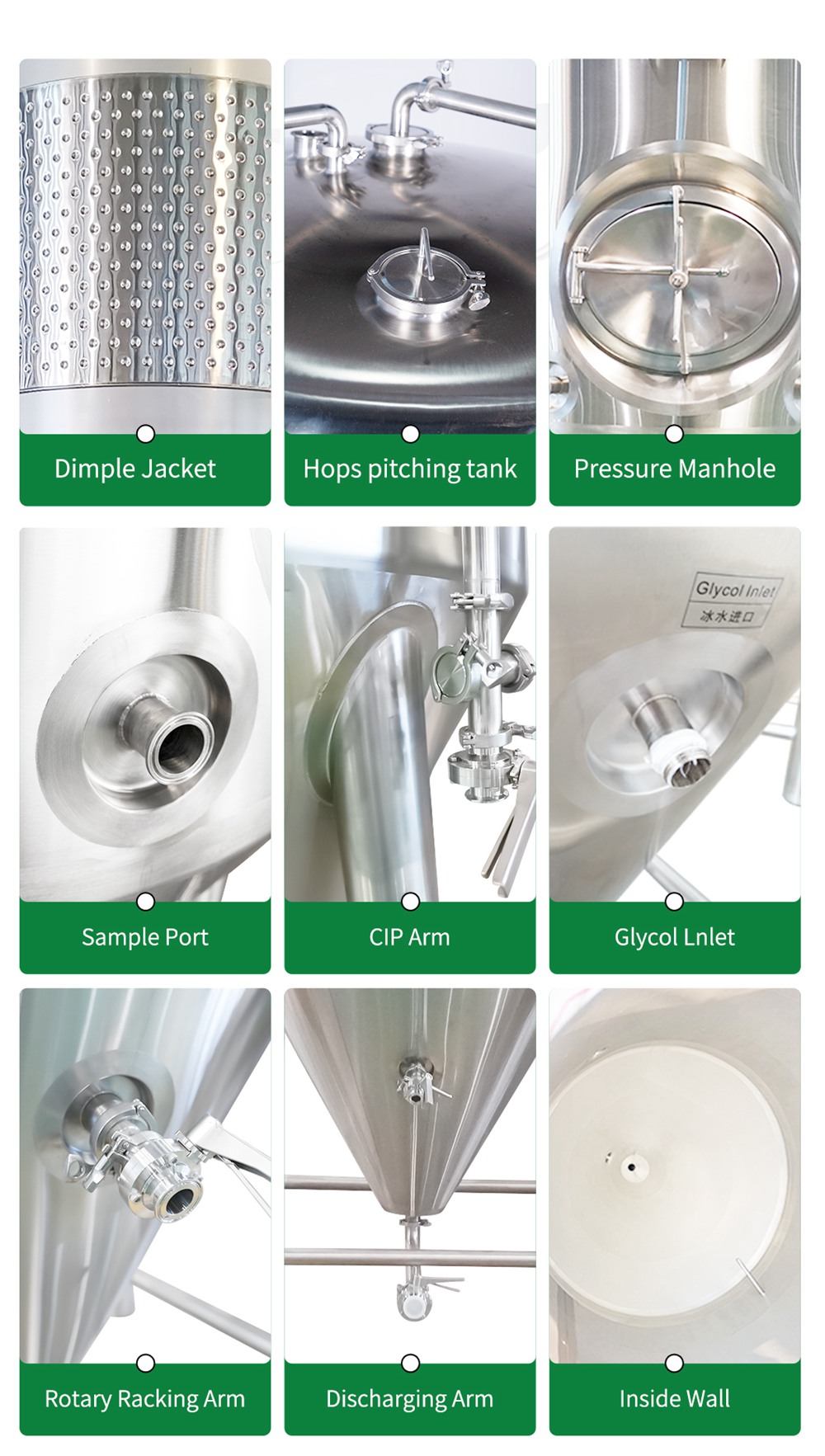

4.Bright Beer Tank Details

5.You may be also Interested in

- Miller

- 1000l Brewhouse

- 1000l Conical Fermenter

- Beer Filter

- Keg Filling Machine

- Keg Washing Machine

- Canning Machine

- Bottling Machine

6.Cases

7.Tiantai Company Profile

Tiantai Company, based in Jinan, China, is a well-recognized manufacturer in the beer and beverage equipment industry, offering complete production lines and turnkey solutions for breweries and beverage projects worldwide.With over 23 years of industry experience since 2001, the Tiantai team has been part of the rapid evolution of brewing technology. Officially established in 2012 during the rise of the craft beer and beverage boom, Tiantai has remained committed to the research and development of advanced brewing processes, fully customized equipment, automated control systems, and data-driven production management. To date, Tiantai has provided equipment and solutions to more than 2,600 beverage facilities across the globe, earning a strong reputation for quality, innovation, and reliable service.

Contact Information:

Email: [email protected]

Contact Person: Hubert Hu