—Product Introduction

Our 700L and 7000L Secondary Yeast Propagation Tanks are engineered to meet the demands of professional breweries, supporting safe and efficient large-scale cultivation of vigorous yeast. Ideal for both craft beer production and brewery expansion, these systems deliver reliable yeast viability and superior fermentation performance.

—Key Features

Construction Material:

Made from food-grade SUS 304 Stainless Steel, offering outstanding corrosion resistance, cleanability, and long-term reliability.

Sanitary Welding Technology:

All seams are precision welded with 100% TIG Argon Gas Welding — delivering smooth, crevice-free joints and a fully hygienic interior.

Dual-Stage Propagation Setup:

Specifically configured for secondary yeast propagation, this design promotes maximum yeast health before transfer to primary fermentation vessels.

Advanced Temperature Management:

Features dimple-jacket cooling with glycol compatibility for accurate thermal control, maintaining optimal yeast propagation conditions.

Integrated Aeration System:

Comes with a built-in aeration stone and sanitary valving for precise management of dissolved oxygen, boosting yeast multiplication.

CIP-Compatible Design:

Equipped with a 360° rotating spray ball and dedicated CIP port to enable thorough, automated internal cleaning.

Available Models:

700L Yeast Propagation Tank | 7000L Yeast Propagation Tank

| Application | Secondary Yeast Propagation | Secondary Yeast Propagation |

| Accessories | Aeration Stone, Pressure Gauge, Sampling Valve, Sight Glass, CIP Arm, Thermometer | Aeration Stone, Pressure Gauge, Sampling Valve, Sight Glass, CIP Arm, Thermometer |

| Temperature Control | Dimple Jacket for Glycol Cooling | Dimple Jacket for Glycol Cooling |

| Pressure Rating | ≤ 2 bar (Adjustable) | ≤ 2 bar (Adjustable) |

| Surface Finish | Internal Ra ≤ 0.4μm Mirror Polish | Internal Ra ≤ 0.4μm Mirror Polish |

| Welding Method | 100% TIG Argon Arc Welding | 100% TIG Argon Arc Welding |

| Material | SUS 304 Food-Grade Stainless Steel | SUS 304 Food-Grade Stainless Steel |

| Volume | 700 Liters (Net) | 7000 Liters (Net) |

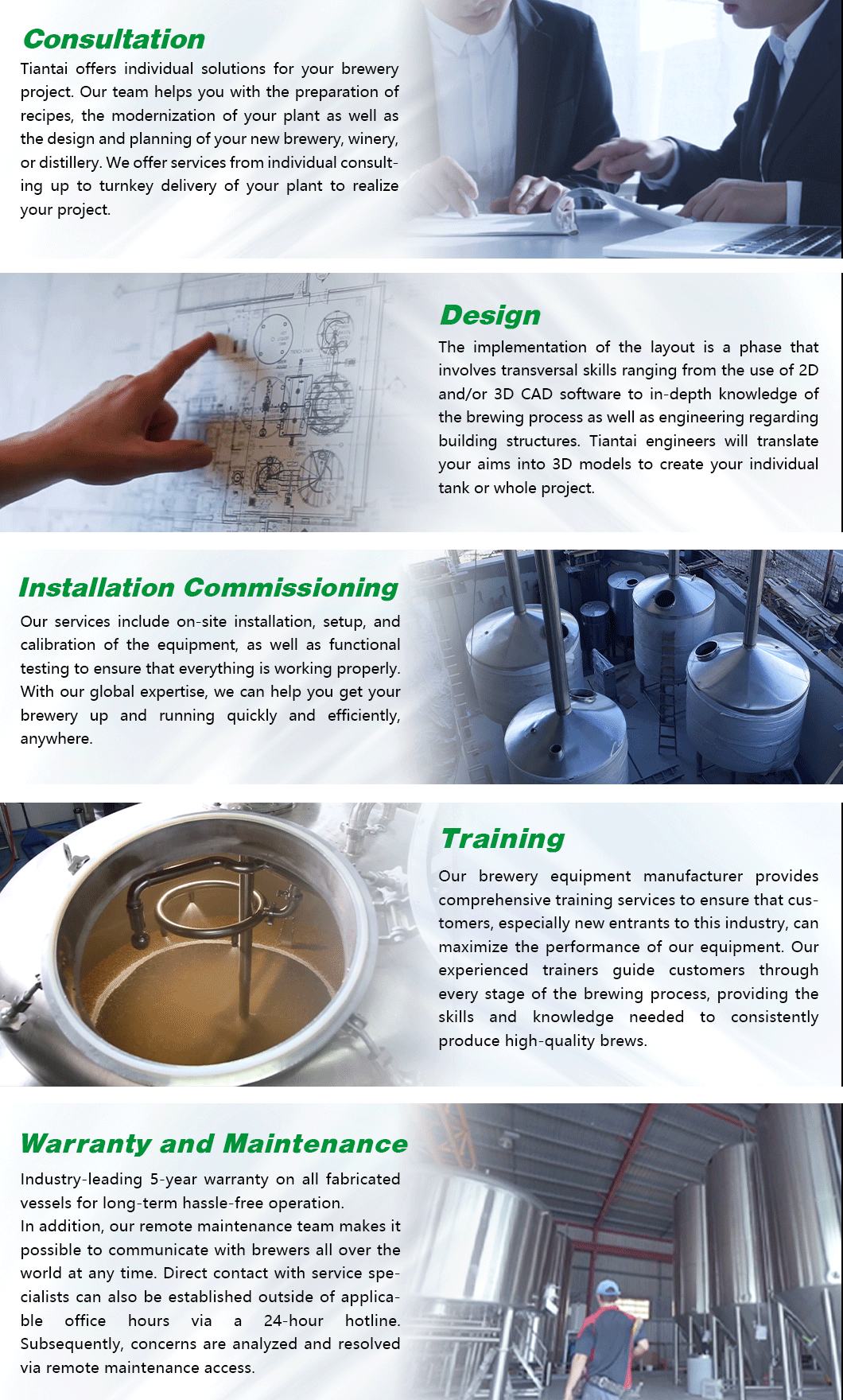

TIANTAI turnkey brewery plants offer innovative solutions and cutting-edge technology to help you achieve your brewing dreams. With Tiantai you can trust that your brewery project will be in expert hands from start to finish. As a general contractor, Tiantai supplies turnkey solutions for the entire brewery. We manufacture precisely matched brewery systems developed according to energy and economic aspects. With our decades-long experience in integrative systems construction, we have successfully completed a multitude of turnkey projects all around the globe.

Learn more how Tiantai beer equipment company to not only produce the best quality brewery equipment for flavor-rich beers, but also help them to optimize the configuration, maximize process uptime and reduce beer loss when they brewing, PLEASE DON’T HESITATE TO CONTACT WITH US!

Hubert

Email: [email protected]