1.Production Description

Tiantai Brewtech is specialize in Semi Automatic Bottle Filler Bottle Capper Bottling Machine, providing high-efficiency and intelligent filling line solutions for the beer and beverage industry. The bottling machine includes filling and capping function. Apply for Glass bottle and crown cap.

We are a globally recognized manufacturer of brewing and distilling equipment based in China. With years of experience and a commitment to innovation, Tiantai provides complete turnkey solutions for breweries and beverage projects worldwide. Whether you’re producing beer, distillery, wine, kombucha, hard seltzer, cider, cold brew coffee, RTD drinks, Soju, Sake, or other beverages, Tiantai has the expertise and equipment to meet your needs.

2. Main components

| Function: Bottle Filling and Capping |

| 10 filling stations and 10 capping stations with Cylinder |

| Capacity: 600-800 bottles/hr |

| Bottle Style: 330ml to 2000ml Glass bottle |

| Siemens programmable Controller |

| CO2 pressured |

| Work Process: Place bottles-CO2 Pressurized-CO2 Pressurized–Filling-Pressure Stabalization-Pressure relief-Stop-Move to capping-Capping-Finish |

| Weight: 450kg |

| Dimension: 2000x800x2400mm |

3.Features

–PLC programmable controller automatically controls the whole process, and the parameters can be adjusted.

–Filling and capping can be completed in one machine at a time

–Equipped with CO2 replacement.

–Adopting isobaric filling method, unique pressure maintenance system, stable and reliable, low beer loss.

–Automatic beer replenishment in the pressure stabilizing tank.

4.Technologies and Services

1) Study/Costing

We provide you with competent and consistent support during the evaluation of your investment.

2) Technical Support

We offer: 2D/3D drawings, Layout plan, Interactions with civil engineering work.

3) Manufacturing

Using modern manufacturing techniques, we produce precise, high quality stainless steel tanks.

4) Installation

Our company has professional civil and mechanical piping staff, who provide you with on-site guidance and information about their project type.

5) Application/Training

Our training for you: Operator training, Maintenance training, Automation training, Individual training for your specific needs

6) Maintenance

At Tiantai, we offer a remote assistance service that allows our technicians to interact with operators remotely.

7) Optimization

If you have equipment that needs upgrades or retrofitting, we can help you analyze its performance and identify areas for improvement.

8) Spare Parts

No down-time, only on-time.The parts you order from us are the exact same or better than those already installed in your equipment.

5. Complete Production Line for Commercial Brewing Factory Equipment

| Malt Storage System |

| Malt Milling System |

| Brewhouse System |

| Fermentation System |

| Filtration System |

| Maturation and Conditioning |

| Pasteurization System |

| Control System |

| CIP System |

| Hot Water Supply |

| Cold Water Supply |

| Brewing Water Supply |

| Refrigeration System |

| Water De-aeration Systems |

| Reverse Osmosis System |

| Steam Supply System |

| Compressed Air Supply System |

| CO2 Supply System |

| CO2 Recovery System |

| Electricity Supply System |

| High-Gravity Dilution System |

| Packing System (bottles/cans) |

6.Tiantai Company Profile

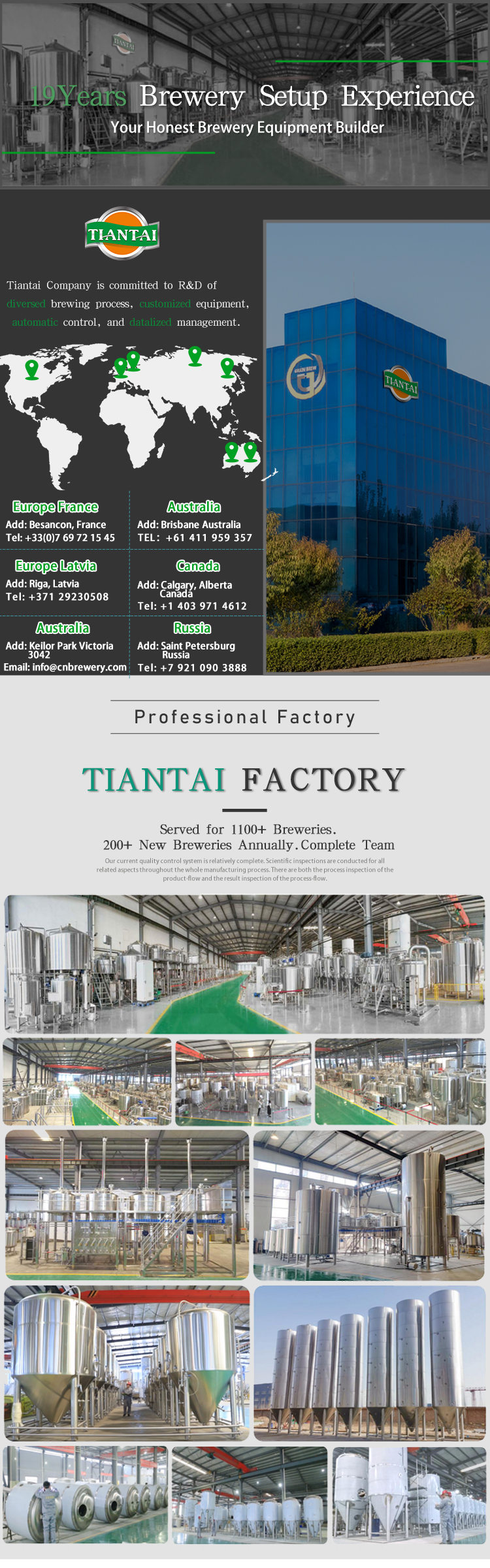

Tiantai Company, a well-recognized manufacturer of beer and beverage equipment industry based in Jinan city of China, provides complete lines and the turnkey service for breweries and beverage projects worldwide. Since 2001, Tiantai team has witnessed the rapid development of the industry with 23 years of experience. Founded in 2012 and followed by the boom of the craft beer market, Tiantai Company is committed to the research and the development of diverse brewing process, customized equipment, automatic control, and datalized management. Up to now, Tiantai Company has served over 2600 breweries in 106 countries with our equipment and solutions along with gaining good reputations.