| General specification for 1200L brewery equipment | ||||

| No. | Name | Components | Capacity | Specification |

| 1 | Grain Milling Unit | Rolling Miller | 300~500kg/hr | Double roller |

| Power:1.5Kw | ||||

| Noise:45±3db | ||||

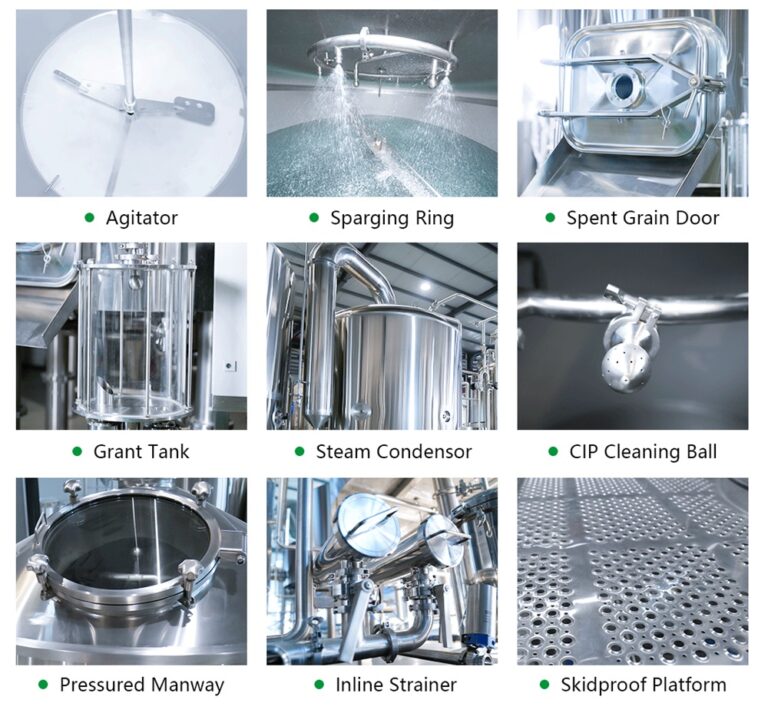

| 2 | Brewhouse Unit | Mash/Lauter tun | 1200L (total 1500L) | Side mounted grain outdoor with grain chute |

| Laser cutting V-wire False Bottom | ||||

| Kettle/Whirlpool Tun | 1200L (total1560L) | Steam heating | ||

| Tangential whirlpool inlet | ||||

| Sanitary leveling sight glass | ||||

| Hot water tank | 1200L (total1380L) | Sanitary leveling sight glass | ||

| Yeast feeder | 20L | Tri clamp aeration port with ball valve | ||

| Heat exchanger | 10M2(Effective area) | Completely 304 SS Corrugated plates | ||

| Pump | 3M3x2PCS | ABB, Sanitary SUS304, VFD control | ||

| Pipe and fittings | As design | completely SS304, Work Platform is included | ||

| 3 | Fermentation unit | Fermenter | 2400L(total 3000L) | Dimple cooling jacket on cone and bottom |

| Side manway | ||||

| Tri clamp CIP ball | ||||

| 60 degree cone bottom | ||||

| Perlick style full sanitary sampling valve | ||||

| Carbonation port and level tube for special request | ||||

| 4 | Filtration unit(optional) | Kieselguhr Filter | 500kg/hr | Power: 1.2kw |

| Filter Area: 1.1M2 | ||||

| SUS304 | ||||

| 5 | Bright beer tank | Bright beer tank | 2500L(total 3000L) | Dimple cooling jacket on cone and bottom |

| Level tube for checking | ||||

| Tri clamp CIP ball | ||||

| Side manway | ||||

| Perlick style full sanitary sampling valve | ||||

| Carbonation port with tri clmap carbonation stone | ||||

| 6 | Glycol Chilling Unit | Glycol Water Tank | 2500L(total 2750L) | Insulated conical top and sloped bottom |

| Chiller | 5HPx2PCS | Cooling Capacity: 11000Kcal/5HP | ||

| Installed Power:5.6kw | ||||

| Refrigerant: Freon R404A ,R410A | ||||

| Noise:70-80db | ||||

| Coperland compressor | ||||

| PVC pipe | As designed | Solenoid valves for glycol inlet to tanks are included | ||

| Glycol water pump | 3M3 | Sanitary SUS304, VFD control | ||

| 7 | Control unit | Brewing and fermetation process Controlling | Floor type | PLC control with touch screen for special |

| PC or mobile remote control for special request | ||||

| 8 | CIP | Caustic Tank | 100L | electric heating element inside, With bimetal thermometer |

| Sterilization Tank | 100L | H2O2 | ||

| Pump | 3M3 | VFD control | ||

| 9 | Keg cleaning | Double Station Keg Rinser | 40-60kegs/hr | Heating: Electric, Power: 15kw(steam for optional) |

| 10 | Keg filling | Single Station Keg Filler | 30-40kegs/hr | Input Power: 0.1 kw |

| 11 | Bottling line | 8 heads | 400-500 bottles/hr | Manual |

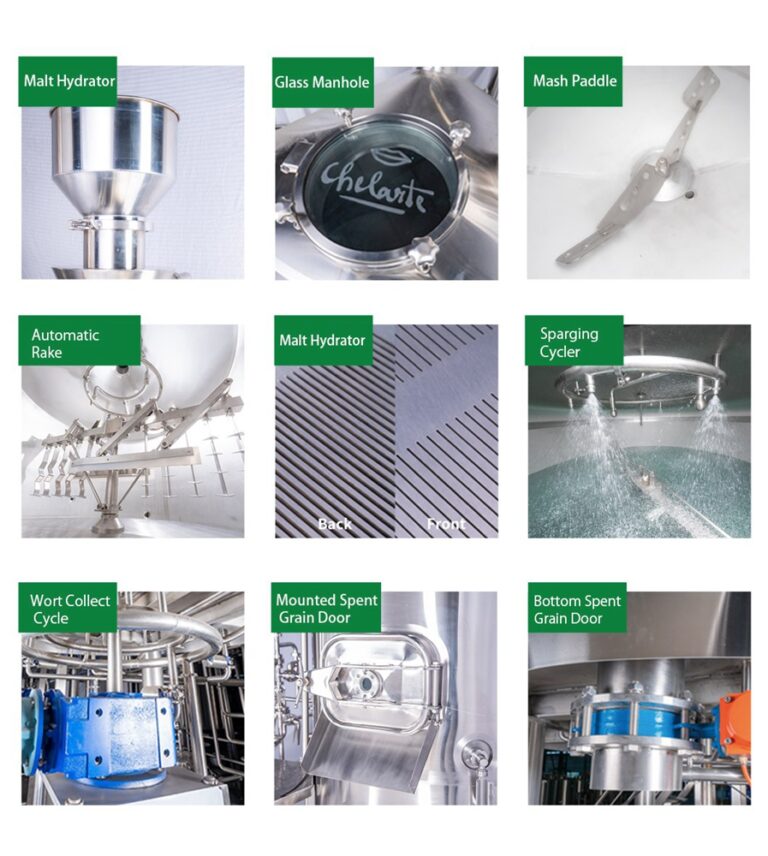

| 12 | Others | Option | Can be Customized | Auger System |

| Grain Case | ||||

| Grist Hydrator | ||||

| Piping flow panel for Brewhouse | ||||

| Brewhouse Separate PLC Controller | ||||

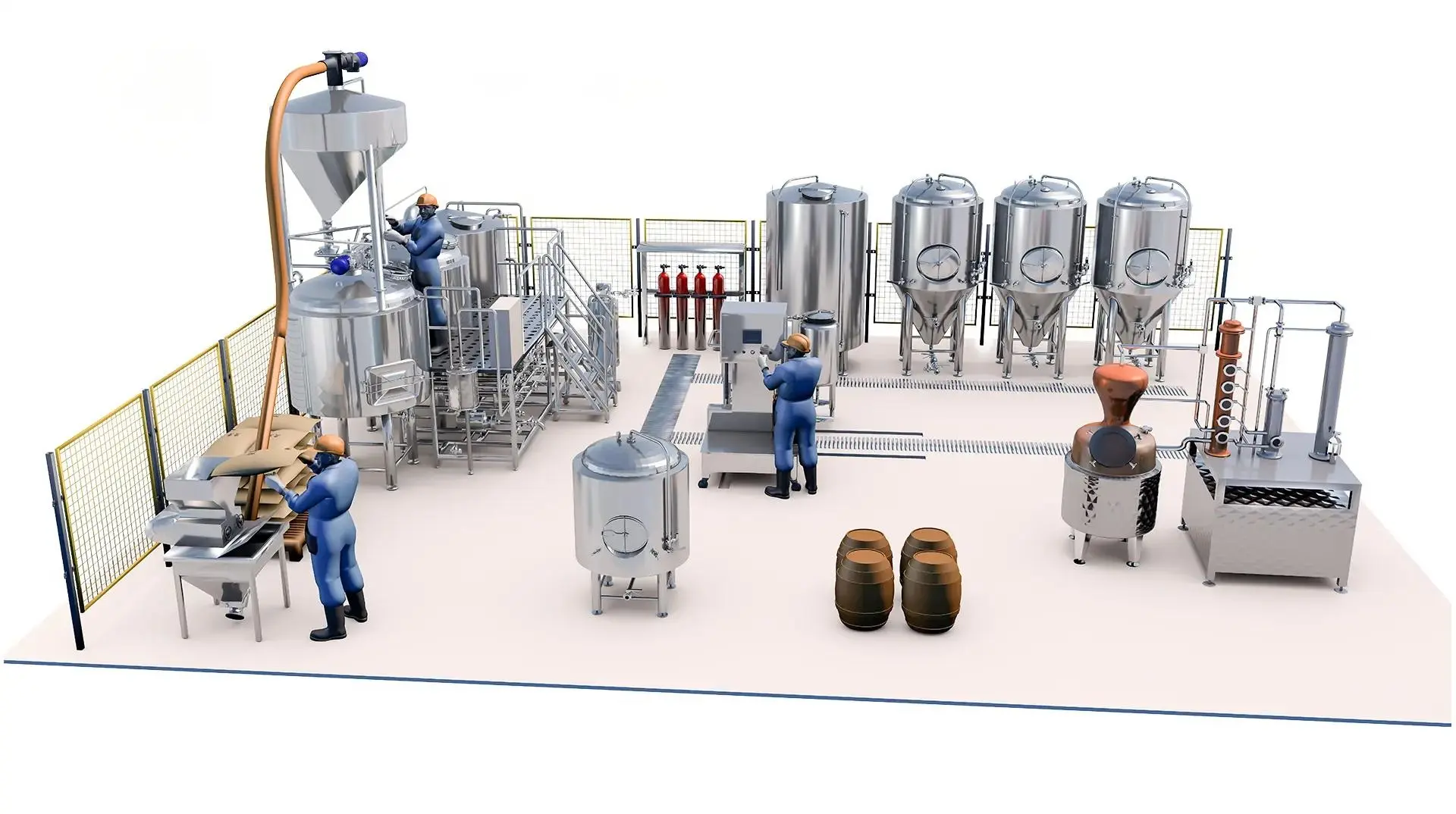

1200L Craft Brewery Equipment

1200L Craft Brewery Equipment is one of Tiantai’s most popular models, ideal for medium-sized craft breweries, brewpubs, and restaurants. With a daily capacity of around 1200L per brew, it provides the perfect balance between flexibility, efficiency, and investment.

This brewing system includes two-vessel or three-vessel brewhouse, 10BBL or 20BBL fermentation tanks, brite tanks, glycol cooling system, CIP unit, and control cabinet. It is designed with a compact layout, high automation options, and durable stainless steel construction, ensuring stable performance and excellent beer quality.

| Capacity / batch | 1200L | 1200L | 1200L |

| Brewing batch / day | 1 | 2 | 3 |

| Brewhouse specification | 2 vessels | 3 vessels | 4 vessels |

| Fermenters specification | 1200L*4 | 2400L*6 | 2400L*8 |

Layout and Process

Tiantai designs the layout according to your site and conducts beer process design to improve site utilization and save energy for you.

Ingredients Storage System

Pallets *8-10 sets

Malt Milling System

Dry mills *1 unit

Brewhouse System

- Mash tun *1 unit

- Lauter tun *1 unit

- Brew kettle *1 unit

- Whirlpool tank *1 unit

- Plate and frame heat exchanger *1 unit

- Wort aeration system *1 set

- Yeast pitching system *1 set

- Supporting pumps, valves, sanitary stainless steel pipes, various sensors, operating platforms, etc.

Fermentation System

- 20HL fermenter *12 units

- 40HL fermenter *14 units

- Supporting pumps, valves, sanitary stainless steel pipes, various sensors, operating platforms, etc.

Filtration System

– Kieselguhr adding tank *1 unit

– Front buffer tank *1 unit

– Kieselguhr mixing tank *1 unit

– Candle filter *1 unit

– Rear buffer tank *1 unit

– Bag trap *1 unit

– Other adding systems are equipped according to the process

– Supporting pumps, valves, sanitary stainless steel pipes, various sensors, operating platforms, etc.

Maturation and Conditioning

– 40HL bright beer tank *1 unit

– Supporting pumps, valves, sanitary stainless steel pipes, various sensors, operating platforms, etc.

Pasteurization System

– Flash pasteurizer *1 unit

– Buffer tank *1 unit

– Supporting pumps, valves, sanitary stainless steel pipes, various sensors, operating platforms, etc.

Control System

PLC cabinet *1 set

CIP System

– Hot alkali tank *1 unit

– Hot water tank (sterile water tank) *1 unit

– Supporting pumps, valves, sanitary stainless steel pipes, various sensors, etc.

Hot Water Supply

– Hot liquor tank *1unit

– Supporting pumps, valves, sanitary stainless steel pipes, various sensors, etc.

Cold Water Supply

– Cold liquor tank *1 unit

– Supporting pumps, valves, sanitary stainless steel pipes, various sensors, etc.

Brewing Water Supply

– Brewing water tank *1 unit

– Supporting pumps, valves, sanitary stainless steel pipes, various sensors, etc.

Refrigeration System

– Chiller *1 unit

– Glycol water tank *1 unit

– Supporting pumps, valves, sanitary stainless steel pipes, various sensors, etc.

Reverse Osmosis System

– Raw water tank *1 unit

– RO water treatment machine *1 unit

– Supporting pumps, valves, sanitary stainless steel pipes, various sensors, etc.

Steam Supply System

– Steam boiler *1 unit

– Distributor *several set

– Steam pipes, valves, etc

Compressed Air Supply System

– Oil-free air compressors *2 sets

– Air buffer tank *1 sets

– Air dryer *1 sets

– Several filters

– Supporting pumps, valves, etc.

Electricity Supply System

– Power cables

– Signal communication cables

– Cable bridge

– Bridge bracket

– Conduit

Filling System (bottle)

– Depalletizer *1 set

– Rinsing machine *1 unit

– Filling machine *1 unit

– Capper machine *1 unit

– Tunnel pasteurizer *1 unit

– Drying Machine *1 unit

– Labelling Machine *1 unit

– Inspection Machine *1 unit

– Packaging Line *1 set

– Palletizer *1 set

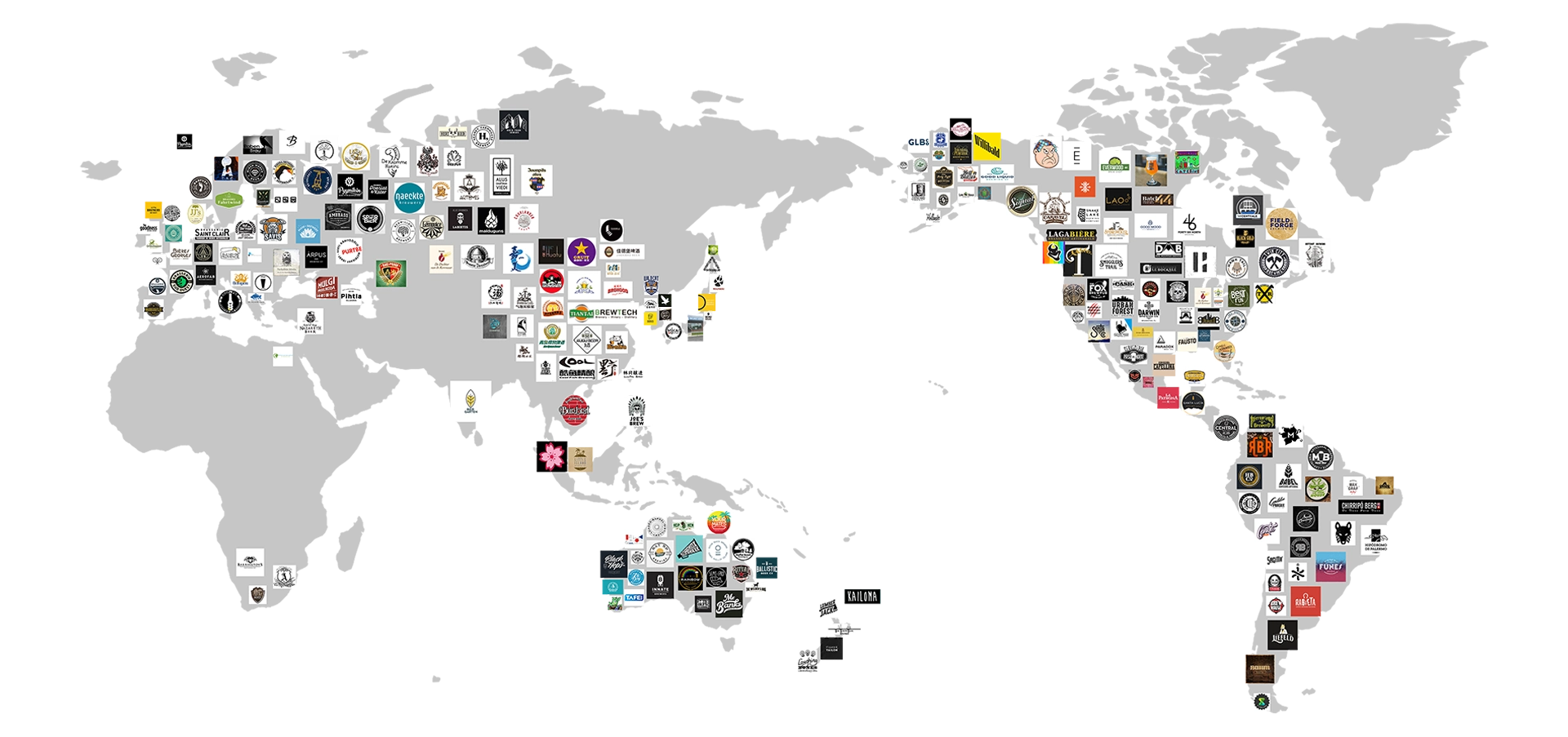

Why Choose Tiantai

Provided services and solutions to more than 2,800+ customers worldwide.

Tiantai designs and engineers complete breweries, covering all activities from malt handling to control, brewing to fermenting, filtering to bottling, and packaging.

As one of the oldest suppliers of brewing, distilling, fermenting and filling equipment in China, Tiantai is recognized not only for high-quality equipment, but also for our technical expertise, design services and superior customer service.

Global Reach

We have solutions in use around the world, and an ever-expanding office network provides accessibility and responsive support. With an unwavering focus on innovation, quality and customer service, we employ highly skilled engineers, technicians and support staff, supported by our global network of agents and distributors.

Sustainability

The company is committed to continuous growth, maintaining a truly customer-focused team culture and being aware of our responsibility to the environment. We prioritize sustainable practices across all aspects of our and our customer’s operations, contributing to a more sustainable future for the industries and the planet.

Customers Say...

Hear directly from those who use Tiantai equipment every day.

Good liquid brewing

America

We also purchased equipment from Shandong Tiantai for 2 different breweries. The customer service is great and we are happy with the quality of the equipment. We highly recommend Shandong Tiantai for all your brewery equipment.

Ballistic Beer

Australia

The reason we chose Tiantai over the other companies were:They had good technical knowledge.They had very competitive pricing.Their salesman wasn’t just a“yes”man, he worked hard to understand all of the specifics we had requested.They were happy to custom build any piece of equipment that I wanted and would indulge my personal preferences for certain items.

Wilddog - Tiemann Beer

Zambia

We have won a Silver medal at the Africa Beer cup with our Shempa Ale in the Alternative beer category.Very happy about this and we are getting used to our Tiantai Brewery.Have also done our first can conditioning which looks promising.

Cerveza fauna

Mexico

We are very happy to be your costumers. I had recommended you several times.We really liked you and your company, and please know that we will tell everyone what a great person you are.

XS Brewing Room

South Korea

l was surprised again because of the stainless steel, finish, and the high-quality finish.People will come to see the breweries around me this weekend, already some brewer checked our equipment yesterday. Thanks for your hard work.

Malandar Brewing

Spain

We have already the equipment at home!!!

lt is sooooo nice!l! Please congratulations for all your team and for the workers that have done it. Amazing job !!

Shimoda Brewing

Japan

Everything is installed, and everything looks really good. We Brew 1 knocking out now.Thanks to you Helen and all Team Tiantai.We were pretty impressed with the brew system overall.

Brasserie de Puyricard

France

That is a very good news.

l always give very good feed back for Tiantai because l appreciate our relationship and your products. So now I know that you have more and more Clients in France, congratulations.