3000L Micro Beer Brewery Equipment

The 3000L Large Beer Brewery Equipment is widely used in industrial and commercial breweries, where the finished beer is typically packaged in bottles or cans for retail sale.

3000L three vessel brewhouse includes mash tun, lauter tun, kettle/whirlpool tun, for 1 to 4 batches per day brewing.

Fermenters can be 3000L, 6000L,9000L or 12000L to accommodate various beer styles with different fermentation cycles.

A fully functional setup includes:Automatic control system,Malt milling system,CIP (Clean-in-Place) system,Glycol cooling system,Steam heating system,Compressed air system,RO water supply system

This comprehensive configuration ensures stable, efficient, and scalable beer production for commercial use.

| Capacity / batch | 2000L | 2000L | 2000L |

| Brewing batch / day | 1 | 2 | 3 |

| Brewhouse specification | 2 vessels | 3 vessels | 4 vessels |

| Fermenters specification | 2000L*10 | 4000L*10 2000L*2 | 6000L*10 4000L*2 |

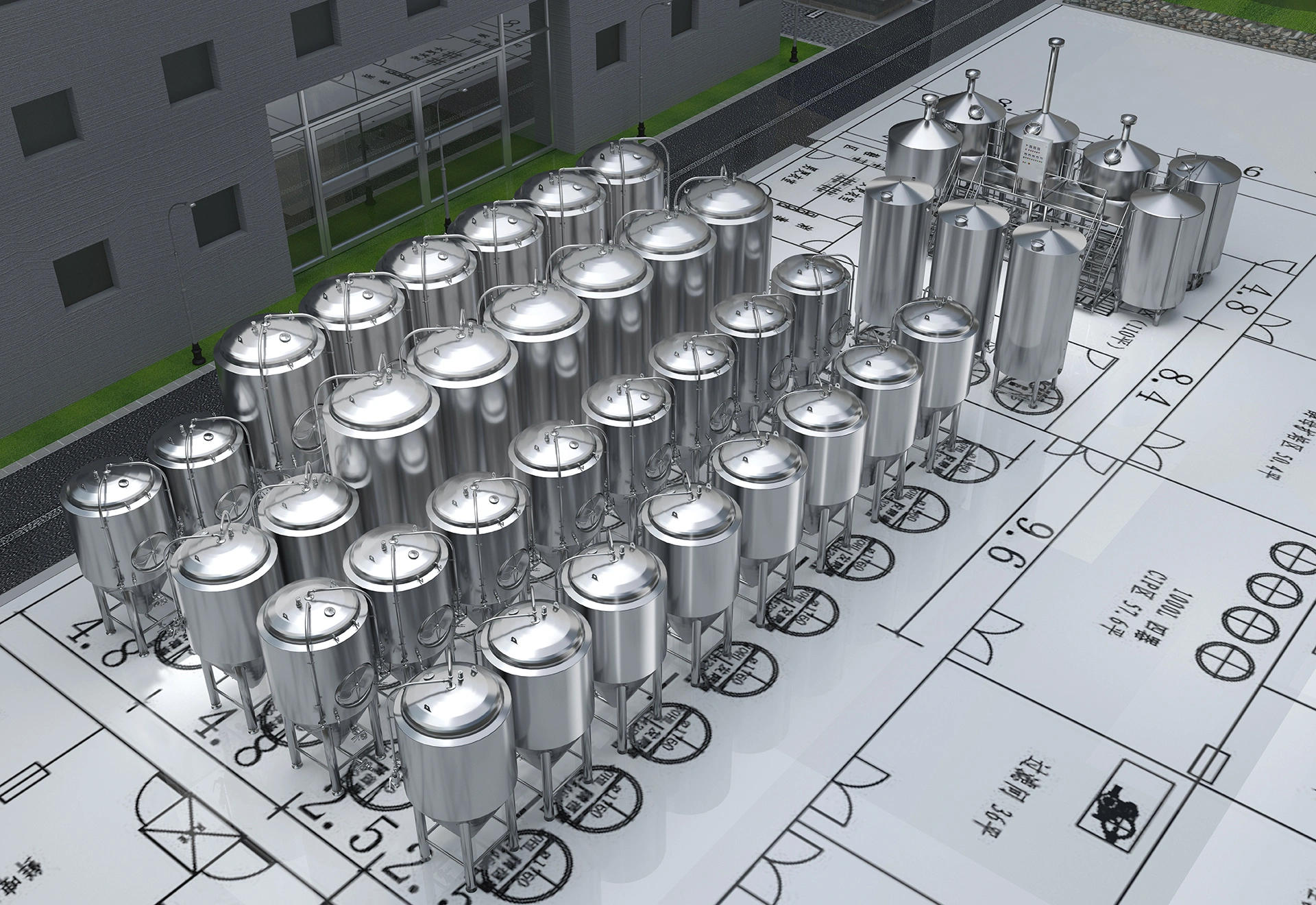

Layout and Process

Tiantai designs the layout according to your site and conducts beer process design to improve site utilization and save energy for you.

Pallets *8-10 sets

Dry mills *1 unit

- Mash tun *1 unit

- Lauter tun *1 unit

- Brew kettle *1 unit

- Whirlpool tank *1 unit

- Plate and frame heat exchanger *1 unit

- Wort aeration system *1 set

- Yeast pitching system *1 set

- Supporting pumps, valves, sanitary stainless steel pipes, various sensors, operating platforms, etc.

- 30HL fermenter *10 units

- 60HL fermenter *20 units

- Supporting pumps, valves, sanitary stainless steel pipes, various sensors, operating platforms, etc.

– Kieselguhr adding tank *1 unit

– Front buffer tank *1 unit

– Kieselguhr mixing tank *1 unit

– Candle filter *1 unit

– Rear buffer tank *1 unit

– Bag trap *1 unit

– Other adding systems are equipped according to the process

– Supporting pumps, valves, sanitary stainless steel pipes, various sensors, operating platforms, etc.

– 60 HL bright beer tank *1 unit

– Supporting pumps, valves, sanitary stainless steel pipes, various sensors, operating platforms, etc.

– Flash pasteurizer *1 unit

– Buffer tank *1 unit

– Supporting pumps, valves, sanitary stainless steel pipes, various sensors, operating platforms, etc.

PLC cabinet *1 set

– Hot alkali tank *1 unit

– Hot water tank (sterile water tank) *1 unit

– Supporting pumps, valves, sanitary stainless steel pipes, various sensors, etc.

– Hot liquor tank *1unit

– Supporting pumps, valves, sanitary stainless steel pipes, various sensors, etc.

– Cold liquor tank *1 unit

– Supporting pumps, valves, sanitary stainless steel pipes, various sensors, etc.

– Brewing water tank *1 unit

– Supporting pumps, valves, sanitary stainless steel pipes, various sensors, etc.

– Chiller *1 unit

– Glycol water tank *1 unit

– Supporting pumps, valves, sanitary stainless steel pipes, various sensors, etc.

– Raw water tank *1 unit

– RO water treatment machine *1 unit

– Supporting pumps, valves, sanitary stainless steel pipes, various sensors, etc.

– Steam boiler *1 unit

– Distributor *several set

– Steam pipes, valves, etc

– Oil-free air compressors *2 sets

– Air buffer tank *1 sets

– Air dryer *1 sets

– Several filters

– Supporting pumps, valves, etc.

– Power cables

– Signal communication cables

– Cable bridge

– Bridge bracket

– Conduit

– Depalletizer *1 set

– Rinsing machine *1 unit

– Filling machine *1 unit

– Capper machine *1 unit

– Tunnel pasteurizer *1 unit

– Drying Machine *1 unit

– Labelling Machine *1 unit

– Inspection Machine *1 unit

– Packaging Line *1 set

– Palletizer *1 set

Brewhouse

- 3000L three vessel brewhouse: mash tun + lauter tun + kettle/whirlpool tun

- Hot water tank and cold water tank for brewing water supply

- Sanitary welded thermowell for high accuracy temperature sensor

- Brewhouse tanks insulation layer is aluminum silicate fiber for excellent heat resistance

- Overall acid washing and passivation, inside polishing to 0.2~0.4μm with no dead corner

- Glass hydrator with pneumatic flat valve for auto malt feeding

- Auto lifted grain rake and dozer for easy spent grain discharging

- Wort collection ring and back pressure flushing device at bottom

- Inner heater calandria in kettle tun, increase heat exchange area, ensure efficient mixing.

- Whirlpool tun tangential inlet pipe bend radius ≥200mm, less resistance, 3-5m/s entrance velocity

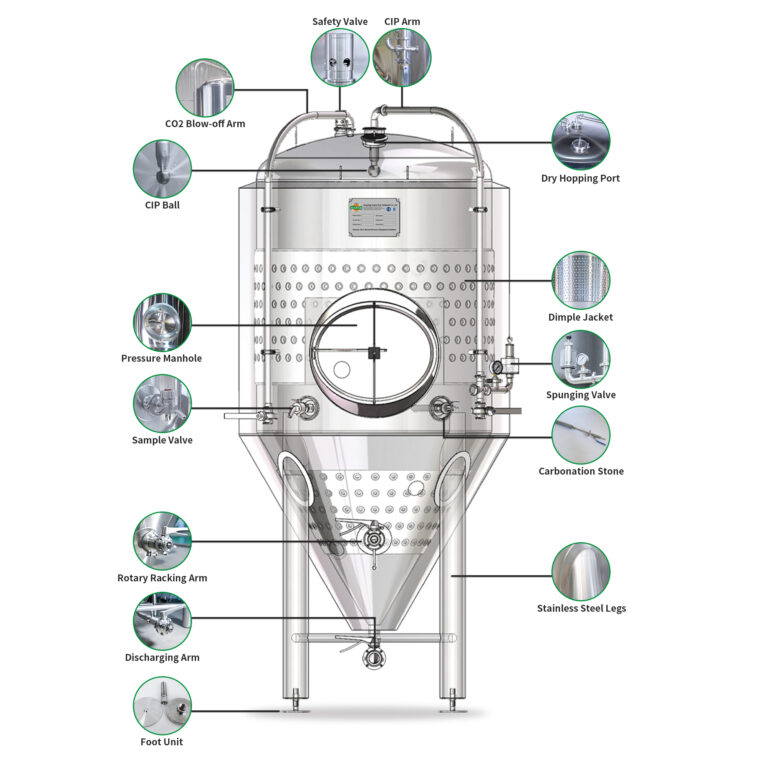

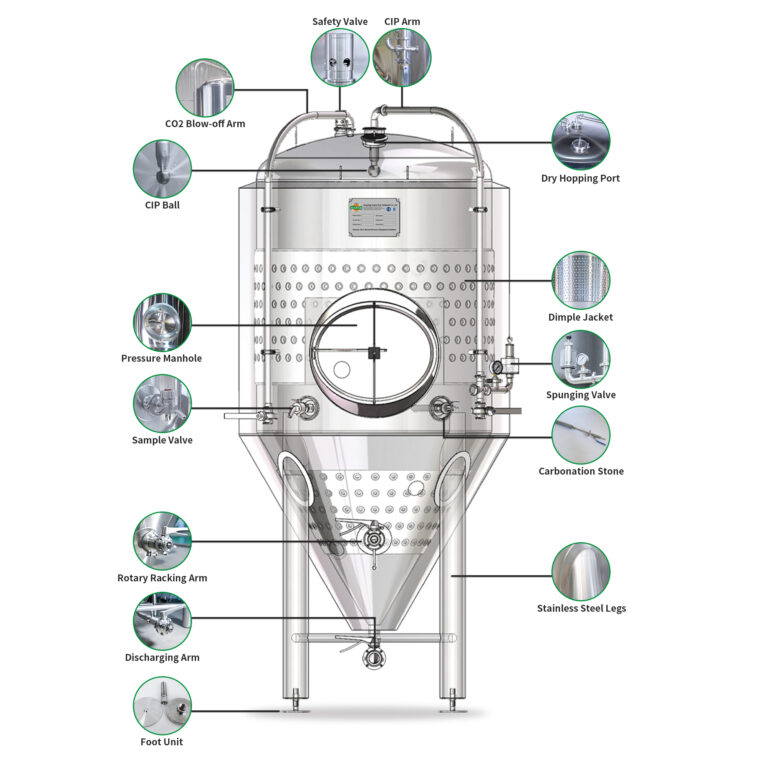

Fermentation System

- Wort fermentation or maturation

- 100% TIG welding with pure argon gas shield

- Interior Finish: Sanitary 2B finish, Pickled and Passivated

- Exterior Finish: Oil brushed finish

- Interior full polished to 0.2~0.4 μm without dead corner

- Insulation: TH=100mm with low thermal conductivity PU

- Cooling Jacket: Dimple plate on bottom and side wall, welded without over burning

- Tank Working Pressure: ≦ 2bar/30psi

- Top mounted double clamp 360° rotary CIP spraying ball and port, 1pc

- Mechanical safe valve PVRV 2bar/30psi on top

- Full sanitary sampling valve with EPDM seal

- Hydraulic shock pressure gauge on CIP arm

- Horizontal mounted rotating racking arm with butterfly valve

- Discharge arm with butterfly valve, removable and easy to clean

- Dry hopping port 4” with solid end cap

Filling and Packaging System

- Depalletizer

- Rinsing machine

- Filling machine

- Capping machine

- Tunnel pasteurizer or flash pasteurizer

- Drying machine

- Labeling machine

- Date printer machine

- Level detection machine

- Automatic carton packing machine

- Carton date printer machine

- Automatic PE film shrink packing machine

- Palletizer

- Belt conveyor

Packaged Style | Size | Capacity |

Glass Bottles | 330ml / 500ml | 2000-3000 bottles/hour |

Cans | 330ml / 500ml | 2000-3000 cans/hour |

Beer Kegs | 20L / 30L / 50L | 60–100 kegs/hour |

PET Bottles | 500ml / 1L | 2000-3000 bottles/hour |

The packaging line can be configured as a mixed production line of single or multiple packaging formats according to product strategy | ||

Automation

- SIEMENS S7-1200/S7-1500 program and touch screen

- Automatic water mixing station

- Automatic wort cooling station

- Mashing stage temperature control and curve storage

- Recipe data storage procedure

- Pressure transmitter for liquid level monitoring

- Proximity switch on the manhole

- Empty level sensor to protect the wort pump

- Foam sensor to control the boiling process

- Automatic rising-lowering rake in the lauter tun

- Pressurized dynamic boiling in the kettle tun

- PH online detection sensor on the mashing water pipeline

Product Details

We are confident in our ability to deliver high-quality products and services to our customers.

Customers Say...

Hear directly from those who use Tiantai equipment every day.

Good liquid brewing

We also purchased equipment from Shandong Tiantai for 2 different breweries. The customer service is great and we are happy with the quality of the equipment. We highly recommend Shandong Tiantai for all your brewery equipment.

Ballistic Beer

The reason we chose Tiantai over the other companies were:They had good technical knowledge.They had very competitive pricing.Their salesman wasn’t just a“yes”man, he worked hard to understand all of the specifics we had requested.They were happy to custom build any piece of equipment that I wanted and would indulge my personal preferences for certain items.

Wilddog - Tiemann Beer

We have won a Silver medal at the Africa Beer cup with our Shempa Ale in the Alternative beer category.Very happy about this and we are getting used to our Tiantai Brewery.Have also done our first can conditioning which looks promising.

Cerveza fauna

We are very happy to be your costumers. I had recommended you several times.We really liked you and your company, and please know that we will tell everyone what a great person you are.

XS Brewing Room

l was surprised again because of the stainless steel, finish, and the high-quality finish.People will come to see the breweries around me this weekend, already some brewer checked our equipment yesterday. Thanks for your hard work.

Malandar Brewing

We have already the equipment at home!!!

lt is sooooo nice!l! Please congratulations for all your team and for the workers that have done it. Amazing job !!

Shimoda Brewing

Everything is installed, and everything looks really good. We Brew 1 knocking out now.Thanks to you Helen and all Team Tiantai.We were pretty impressed with the brew system overall.

Brasserie de Puyricard

That is a very good news.

l always give very good feed back for Tiantai because l appreciate our relationship and your products. So now I know that you have more and more Clients in France, congratulations.