Annual 10 Million Liter Brewery Equipment

Brew at Scale. Deliver Excellence. Your 10 Million Liter Brewery Starts Here!

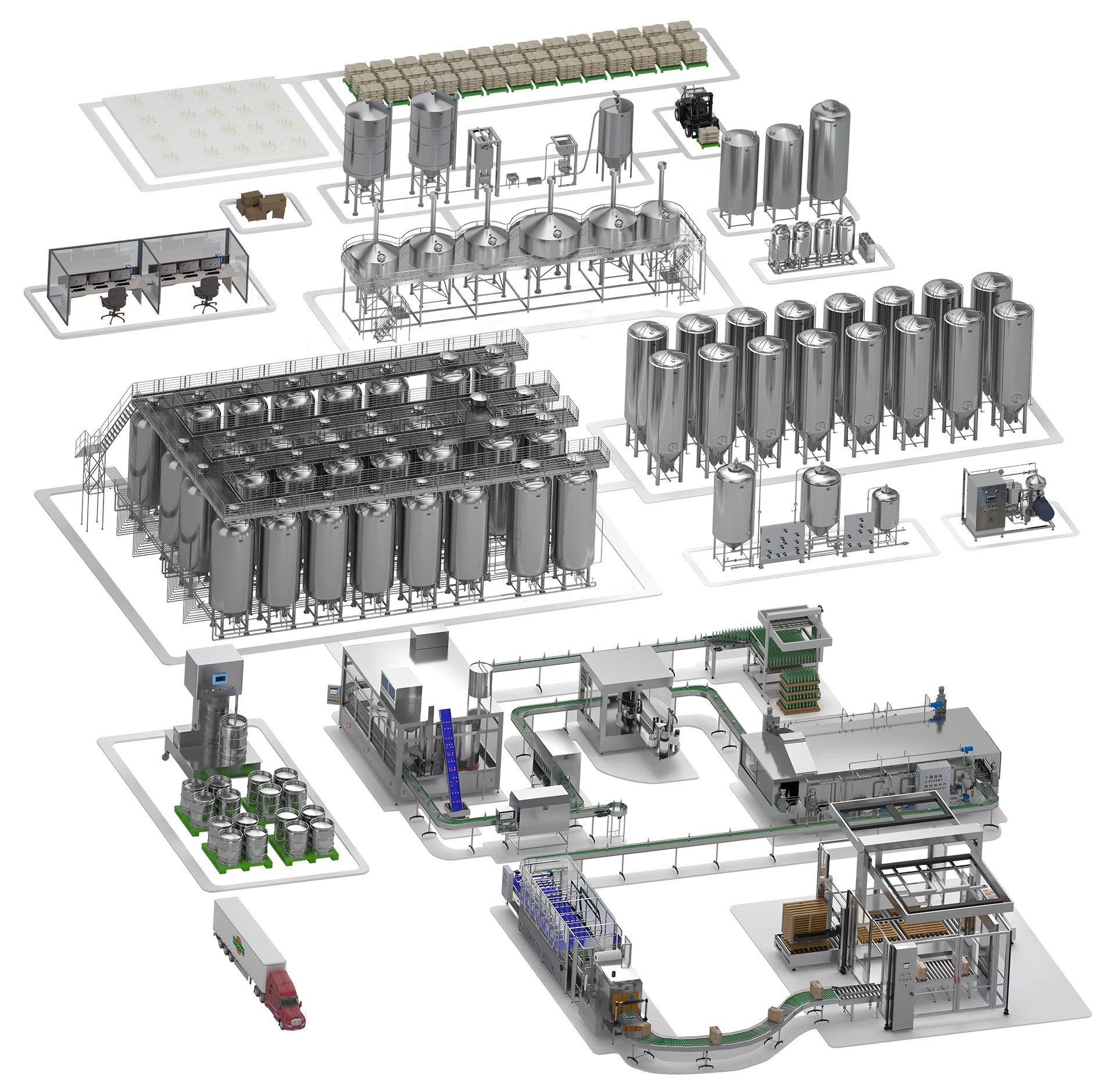

With the diversification and quality development of the global beer consumption structure, regional medium and large breweries have become the key force leading the market. In response to the growing market demand, TIANTAI has launched an overall solution for a brewery with an annual output of 10,000,000 liters (i.e. 10 million liters). The solution covers the entire process from process design, equipment configuration, plant layout to automation control and quality management. It is a highly integrated, replicable and implementable medium and large brewery construction plan.

This solution is not only suitable for new projects, but also for the expansion and upgrading of existing medium-sized breweries. It deeply integrates modern brewing technology with intelligent management systems to achieve the goal of high-efficiency, high-quality and low-energy industrial-grade beer production. It is particularly suitable for layout in regional consumption centers or export-oriented markets, taking into account scale and flexibility.

Annual production of 10 million liters of beer is equivalent to 100,000 hectoliters, about 85,470 barrels (US BBL), or equivalent to 280,000 standard boxes (355ml × 24 bottles). This production capacity is between traditional industrial breweries and craft breweries, which can achieve economies of scale and have certain market flexibility, suitable for serving a country or a regional market.

This capacity matching plan generally recommends a brewing system with 3-6 batches per day and 5000 lts per batch, combined with 20-30 fermentation tanks for multi-batch rotation fermentation, which can ensure stable annual production capacity output and have 10-20% growth redundancy space.

| Capacity/Batch: | 5000 lts |

| Brew Batch / Day: | 6 Batches |

| Annual Working Time: | 300 Days |

| Fermentation Tank: | 30000lts Fermenter * 10sets 20000lts Fermenter *12sets |

Layout and Process

Beer factory space planning: Reasonably distribute production areas, power areas, storage areas, and office/living areas based on the principles of efficiency, safety, environmental protection, and sustainability;

Brewery Equipment

Pallets *8-10 sets

Dry mills *1 unit

- Mash tun *1 unit

- Lauter tun *1 unit

- Brew kettle *1 unit

- Whirlpool tank *1 unit

- Plate and frame heat exchanger *1 unit

- Wort aeration system *1 set

- Yeast pitching system *1 set

- Supporting pumps, valves, sanitary stainless steel pipes, various sensors, operating platforms, etc.

- 20HL fermenter *12 units

- 40HL fermenter *14 units

- Supporting pumps, valves, sanitary stainless steel pipes, various sensors, operating platforms, etc.

– Kieselguhr adding tank *1 unit

– Front buffer tank *1 unit

– Kieselguhr mixing tank *1 unit

– Candle filter *1 unit

– Rear buffer tank *1 unit

– Bag trap *1 unit

– Other adding systems are equipped according to the process

– Supporting pumps, valves, sanitary stainless steel pipes, various sensors, operating platforms, etc.

– 40HL bright beer tank *1 unit

– Supporting pumps, valves, sanitary stainless steel pipes, various sensors, operating platforms, etc.

– Flash pasteurizer *1 unit

– Buffer tank *1 unit

– Supporting pumps, valves, sanitary stainless steel pipes, various sensors, operating platforms, etc.

PLC cabinet *1 set

– Hot alkali tank *1 unit

– Hot water tank (sterile water tank) *1 unit

– Supporting pumps, valves, sanitary stainless steel pipes, various sensors, etc.

– Hot liquor tank *1unit

– Supporting pumps, valves, sanitary stainless steel pipes, various sensors, etc.

– Cold liquor tank *1 unit

– Supporting pumps, valves, sanitary stainless steel pipes, various sensors, etc.

– Brewing water tank *1 unit

– Supporting pumps, valves, sanitary stainless steel pipes, various sensors, etc.

– Chiller *1 unit

– Glycol water tank *1 unit

– Supporting pumps, valves, sanitary stainless steel pipes, various sensors, etc.

– Raw water tank *1 unit

– RO water treatment machine *1 unit

– Supporting pumps, valves, sanitary stainless steel pipes, various sensors, etc.

– Steam boiler *1 unit

– Distributor *several set

– Steam pipes, valves, etc

– Oil-free air compressors *2 sets

– Air buffer tank *1 sets

– Air dryer *1 sets

– Several filters

– Supporting pumps, valves, etc.

– Power cables

– Signal communication cables

– Cable bridge

– Bridge bracket

– Conduit

– Depalletizer *1 set

– Rinsing machine *1 unit

– Filling machine *1 unit

– Capper machine *1 unit

– Tunnel pasteurizer *1 unit

– Drying Machine *1 unit

– Labelling Machine *1 unit

– Inspection Machine *1 unit

– Packaging Line *1 set

– Palletizer *1 set

Brewhouse

It is recommended to use a four-vessel brewshouse system, including a Mash Tun, a Lauter Tun, a Kettle Tun, and a Whirlpool Tun, with an efficient heat recovery system and fully automatic valve control to achieve efficient coordination of mashing, filtration, boiling, and wort whirlpooling.

- Material 304 or 316L stainless steel, with a double-layer jacket structure

- All tanks inside polishing to 0.2~0.4 μm without dead corner

- The heat recovery system can save more than 20% of energy consumption

- The PLC or SCADA system can realize one-button control and remote monitoring of the entire saccharification process.

- Automatic water mixing station and wort cooling station

- High-efficiency Plate Heat Exchanger

- High quality sanitary centrifugal pumps

- Completely 304 stainless steel setup work platform, design by safety standard

- Complete pipes and fittings, all pipes inside polished to sanitary grade, the pipes connection without dead corner

Fermentation System

Beer fermentation tanks are key equipment for primary fermentation and post-aging (storage) in the beer brewing process, and are responsible for the core biochemical process of converting wort into beer. This equipment not only affects the fermentation efficiency and taste quality of beer, but is also an important part of the process flow of modern breweries to achieve automated and standardized production.

- Tank Inner Material: food grade stainless steel SUS304 or SUS316L

- Polishing: inner wall Ra≤0.4μm, ensuring easy cleaning and anti-pollution

- Jacket (cooling zone): Multi-stage distributed cooling jacket, commonly found on the side wall and cone bottom of the tank

- Use ethylene glycol ice water or alcohol solution for cooling control

- Insulation layer: With low thermal conductivity PU, thickness 50-100mm, to ensure constant temperature fermentation

- Shell:Stainless steel brushed or mirrored, beautiful and durable

- Top cover: Equipped with sight glass, CIP spray ball, safety valve, pressure gauge, CO2 inlet, etc.

- Cone bottom:Generally 60°-70° cone angle, which is conducive to yeast precipitation and recovery

- Discharge port/sampling port: The yeast port, middle sampling port and bottom drainage port are set on the side for easy operation and monitoring

- CIP system interface:Realizes on-site cleaning (Clean In Place), can be linked with CIP station

Filling and Packaging System

An efficient, intelligent and diversified brewery packaging line system is an indispensable core link of a modern beer factory. It not only determines the packaging beauty and stability of the products leaving the factory, but also relates to the protection of beer quality and the establishment of corporate brand image.TIANTAI can provide customers with a full set of customized packaging line solutions from bottles, cans to kegs, helping you build beer production capabilities for the future market.

- Equipped with PLC + touch screen operating systems and integrate:

- Keep beer fresh, hygienic, and free of oxidation pollution, while achieving high efficiency, low loss, and high consistency output

- OEE equipment efficiency analysis system

- Bottle/can tracking system (barcode/RFID)

- Quality traceability system (filling data is associated with product number)

- Remote diagnosis and data backup function

- Can connect upstream filling plans and downstream warehousing systems to form a closed-loop supply chain control system

Packaged Form | Size | Capacity |

Glass Bottles | 330ml / 500ml | 6000-12000 bottles/hour |

Cans | 330ml / 500ml | 5000-8000 cans/hour |

Beer Kegs | 20L / 30L / 50L(Euro Standard) | 60–200 Kegs/hr |

PET Bottles | 500ml / 1L | 1000–6000 bottles/hour |

The packaging line can be configured as a mixed production line of single or multiple packaging formats according to product strategy | ||

Brewery Automation Control System

As the beer industry moves from traditional manufacturing to digital factories, automated control systems are no longer an option, but one of the core competitive advantages of brewery construction. TIANTAI can tailor automation solutions from basic PLC control to complete MES system integration based on the size, budget, development stage and technical personnel capabilities of the customer’s brewery.

- Improve production efficiency: reduce manual operations and optimize process flow

- Ensure beer quality: achieve stable fermentation and filling through precise control

- Reduce energy consumption and loss: intelligently schedule energy and material use

- Achieve information traceability: fully record production data for easy supervision and optimization

- Assist digital transformation: provide data interface for brewery management system (ERP/MES/SCADA)

- Brewhouse Automation Control: Control the temperature curve, pump speed, and stirring time of the mash tun; Precisely control the timing of boiling and adding hops; Fully automatic wort transfer and cooling management; Achieve “one-click saccharification” or automatic switching of production modes.

- Fermentation & Maturation Automation Control: Automatic temperature control system (with alarm); CO₂pressure control and safety valve monitoring; Precise control of yeast dosage, automatic sampling device; Intelligent yeast drainage/cleaning/water replenishment system; Unmanned operation and data recording of the entire fermentation process.

- Cleaning in Place: Automatically switch the cleaning cycle path;Full monitoring of cleaning medium concentration, temperature, and flow; Timed start/linkage with equipment shutdown for cleaning; Water saving, energy saving, and hygiene and safety assurance

- Packaging Automation: Filling level control, sealing pressure/speed adjustment; Empty bottle identification, abnormal rejection; Automatic labeling/inkjet control, linkage detection system; Coordinated operation with the back-end palletizing system;Whole line linkage start/stop/fault alarm interlock.

- Utility Automation: Centralized control of chillers, steam boilers, air compressors and other equipment; Statistical analysis of refrigerant, water and electricity usage;Real-time energy consumption warning and optimized scheduling.

Customers Say...

Hear directly from those who use Tiantai equipment every day.

Good liquid brewing

We also purchased equipment from Shandong Tiantai for 2 different breweries. The customer service is great and we are happy with the quality of the equipment. We highly recommend Shandong Tiantai for all your brewery equipment.

Ballistic Beer

The reason we chose Tiantai over the other companies were:They had good technical knowledge.They had very competitive pricing.Their salesman wasn’t just a“yes”man, he worked hard to understand all of the specifics we had requested.They were happy to custom build any piece of equipment that I wanted and would indulge my personal preferences for certain items.

Wilddog - Tiemann Beer

We have won a Silver medal at the Africa Beer cup with our Shempa Ale in the Alternative beer category.Very happy about this and we are getting used to our Tiantai Brewery.Have also done our first can conditioning which looks promising.

Cerveza fauna

We are very happy to be your costumers. I had recommended you several times.We really liked you and your company, and please know that we will tell everyone what a great person you are.

XS Brewing Room

l was surprised again because of the stainless steel, finish, and the high-quality finish.People will come to see the breweries around me this weekend, already some brewer checked our equipment yesterday. Thanks for your hard work.

Malandar Brewing

We have already the equipment at home!!!

lt is sooooo nice!l! Please congratulations for all your team and for the workers that have done it. Amazing job !!

Shimoda Brewing

Everything is installed, and everything looks really good. We Brew 1 knocking out now.Thanks to you Helen and all Team Tiantai.We were pretty impressed with the brew system overall.

Brasserie de Puyricard

That is a very good news.

l always give very good feed back for Tiantai because l appreciate our relationship and your products. So now I know that you have more and more Clients in France, congratulations.