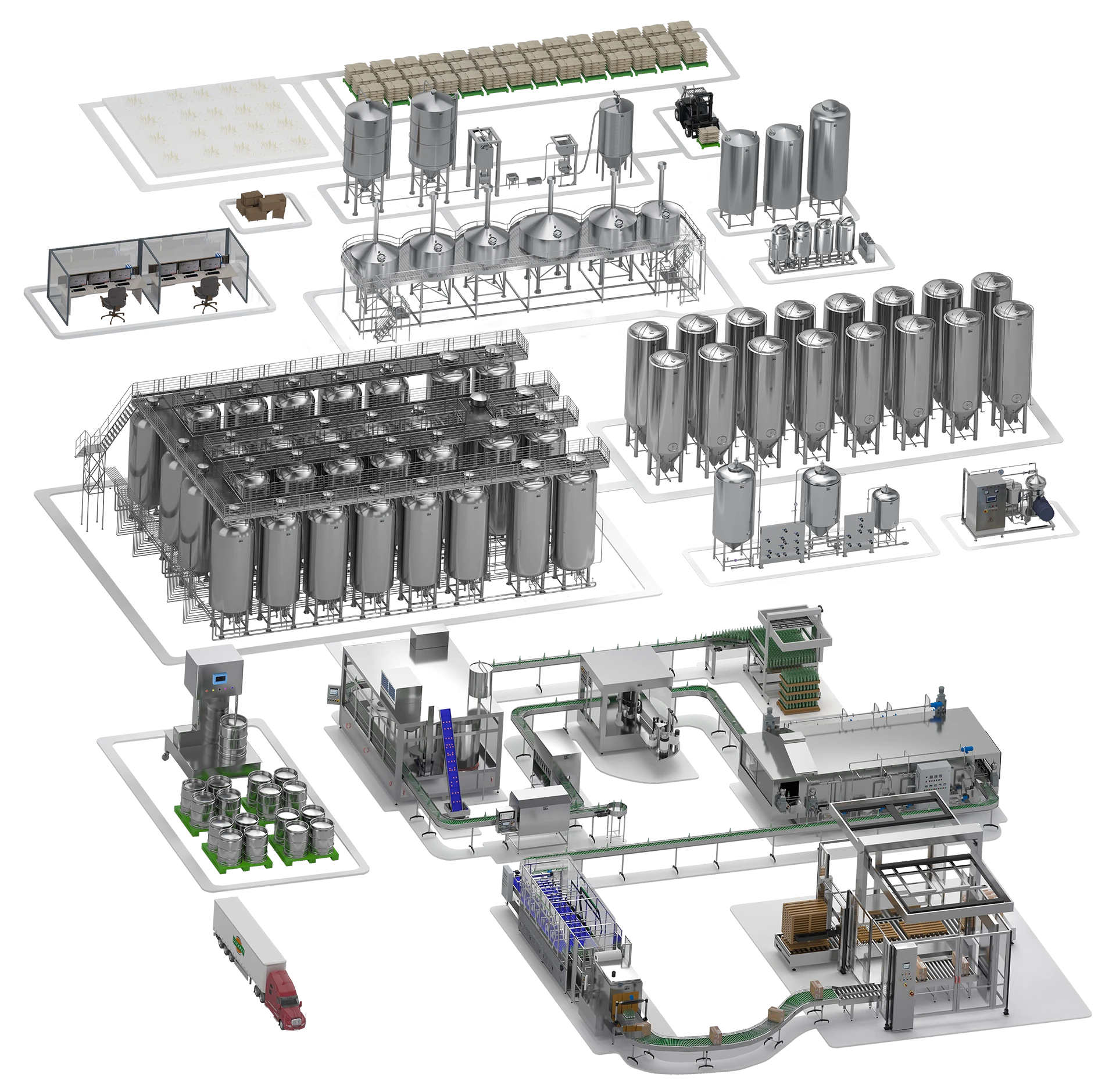

| General specification for Annual Output 30000 ton/3 Million Beer Brewing Line | ||||

| No. | Name | Components | Capacity | Parameter |

| 1 | Grain & Milling Unit | Malt metering bin | 15m³ | Stainless steel tank, store for malts |

| Rice metering bin | 5m³ | Stainless steel tank, store for rice | ||

| Convey for malts, rice | Bucket elevator, Stoning machine Permanent magnetic drum, weighing sensor |

|||

| Malt wet grinding machine | 12 ton /hr | Automatic control | ||

| Rice Miller Machine | 5Ton/Hr | Stainless steel machine, Roll spacing adjustment and automatic centering function, Feed water mixing and water temperature regulation system |

||

| Mash Transfer | Stainless steel pipes | |||

| 2 | Brewhouse Unit | Cooker Tun | 80HL | Cooking rice, Steam jacket on bottom and side Agitator inside |

| Mash tun | 150HL | Steam jacket on bottom and side Agitator inside Wort hydrator mounted top of mash tun |

||

| Lauter tun | 150HL | Grain rake with VFD Laser cutting V-wire False Bottom Easyclean and detachable sparging spray ring Multihole wort collect ring & Anti-rinser(optional) |

||

| Buffer Tun | 150HL | Store wort, Steam heating, insulation thickness 150mm |

||

| Kettle Tun | 150HL | Built-in circulating heating Steam vent with condensate ring for kettle stack |

||

| Whirlpool Tun | 150HL | Wort whirlpool, Tangential whirlpool inlet with reducing port |

||

| Hot water tank | 1000HL | Hot water recycle from CLT and supply for mashing, sparging, cleaning | ||

| Heat exchanger | 110m2 | SUS304 plate | ||

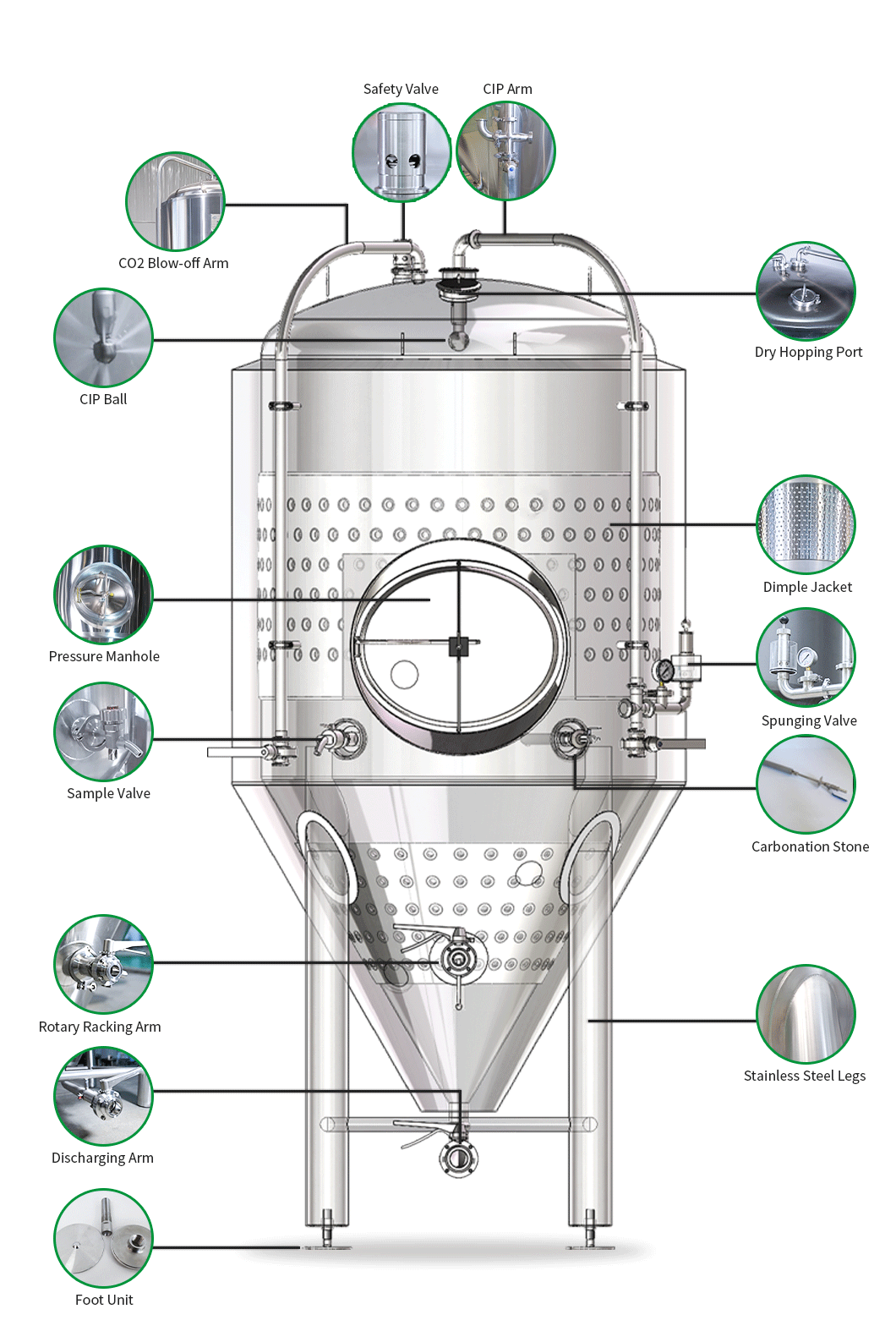

| 3 | Fermentation unit | Fermenter | 150HL *4sets | Glyco cooling jacket on cone and bottom Side or top manway CIP arm and CO2 blow off arm Mechanical relief valve Shockproof pressure gauge Rotating racking arm Dry hopping port Carbonation stone |

| 300HL * 6sets | ||||

| 600HL*24sets | ||||

| 4 | Filtration unit(optional) | Kieselguhr Filter | 5000kg/hr | Pressured candle type DE filter |

| Disk Centrifugal Separator | 5000-8000 L/hr | Centrifugal wine loss rate: ≤ 3% | ||

| 5 | Bright beer tank | Bright beer tank | 300HL * 2sets | Glyco cooling jacket on cone and bottom Side or top manway CIP arm Mechanical relief valve Shockproof pressure gauge Carbonation stone Sight level sensor |

| 600HL*2sets | ||||

| 6 | Glycol Chilling Unit | Glycol Water Tank | 1000HL | Insulated conical top and sloped bottom |

| Cold Water Tank | 1000HL | Dimple plate on side wall | ||

| Chiller | 2sets | Cooling capacity: 300×103 kCal/h, Power 140KW, Cooling water flow rate: 61 m³/h |

||

| Transfer | 1unit | Complete Pipes, Fitting, Pumps | ||

| 7 | Control unit | Brewhouse controlling | Automatic PLC control with touch screen | |

| Fermentation Controling | Automatic PLC control with touch screen | |||

| 8 | CIP | Brewhouse CIP Cleaning System | 6m3 | Five tanks, automatic control |

| Brewhouse CIP Cleaning System | 6m3 | Four tanks, automatic control | ||

| 9 | Others | Option | Can be Customized | Yeast expansion system and recovery system |

| Deoxygenated water and post-dilution | ||||

| Spent grains treatment system | ||||

| RO Water treatment system | ||||

| Steam supply system | ||||

| Beer Bottling Line | ||||

| Beer Canning Line | ||||

| Beer Kegs Line | ||||

| Air Compressor System | ||||