| General specification for 600L brewery equipment | ||||

| No. | Name | Components | Capacity | Specification |

| 1 | Grain Milling Unit | Rolling Miller | 300~500kg/hr | Double roller |

| Power:1.5Kw | ||||

| Noise:45±3db | ||||

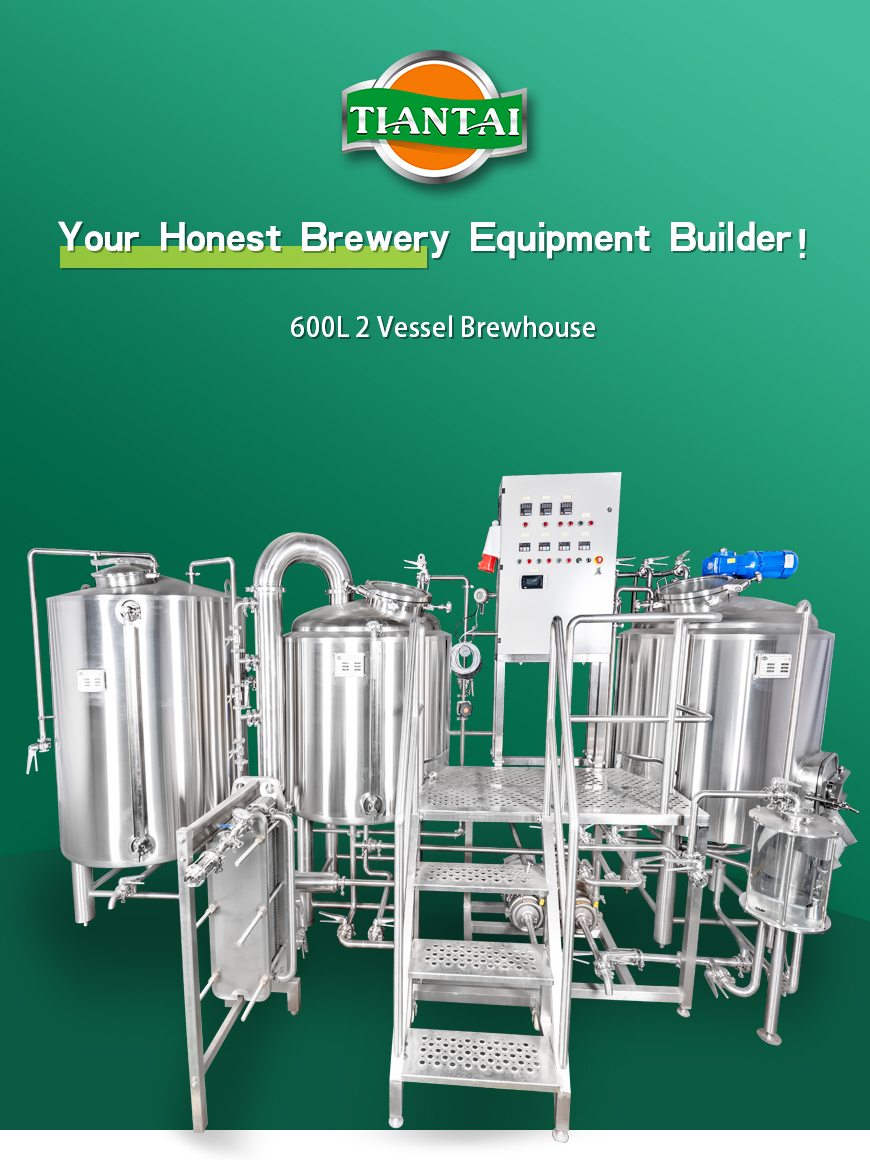

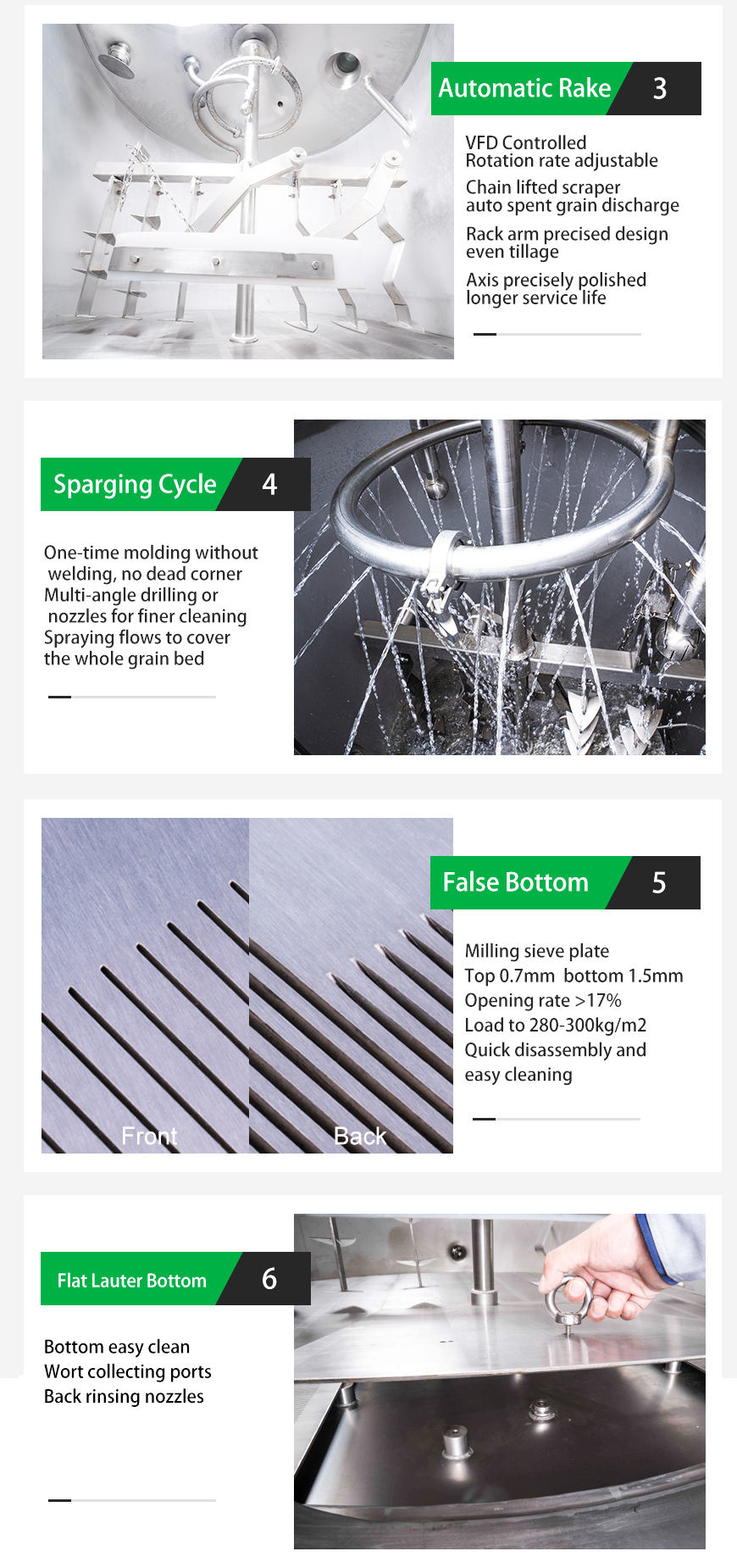

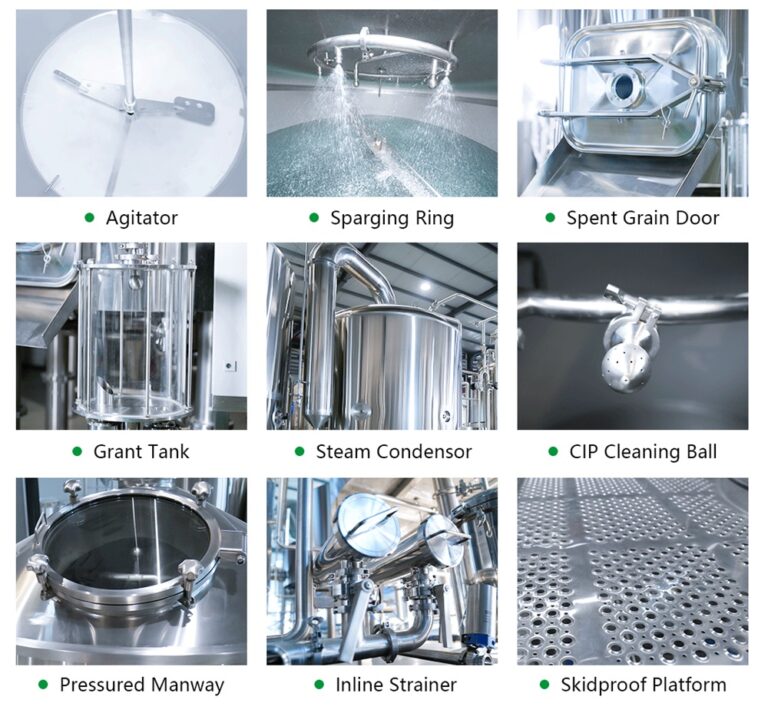

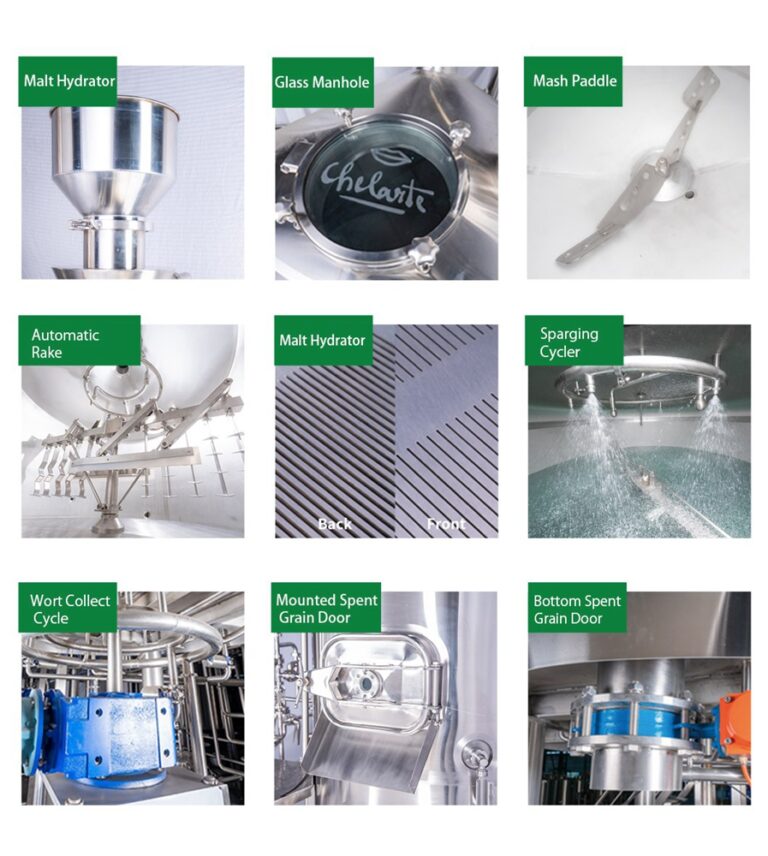

| 2 | Brewhouse Unit | Mash/Lauter | 600L (total 750L) | Side mounted grain outdoor with grain chute |

| Laser cutting V-wire False Bottom | ||||

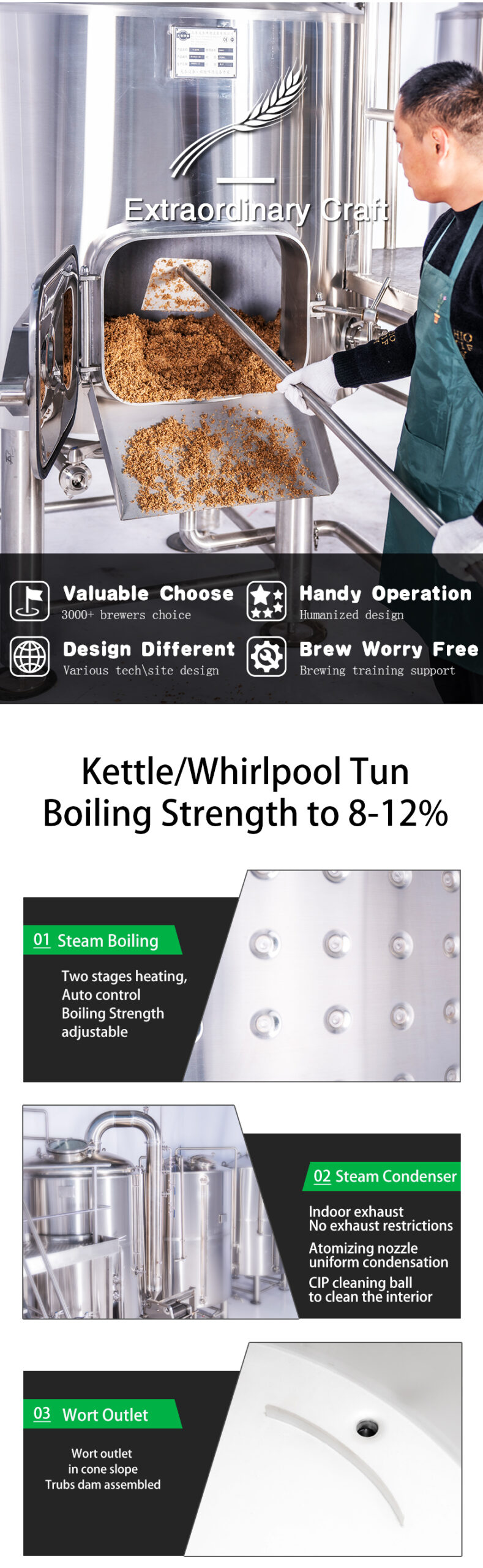

| Kettle/ Whirlpool tun Tun | 600L (total 780L) | Steam heating | ||

| Tangential whirlpool inlet | ||||

| Sanitary leveling sight glass | ||||

| Hot Water Tank | 600L or 1200L | Supply hot water for mashing, sparing | ||

| Yeast feeder | 10L | Tri clamp aeration port with ball valve | ||

| Heat exchanger | 6M2(Effective area) | Completely 304 SS Corrugated plates | ||

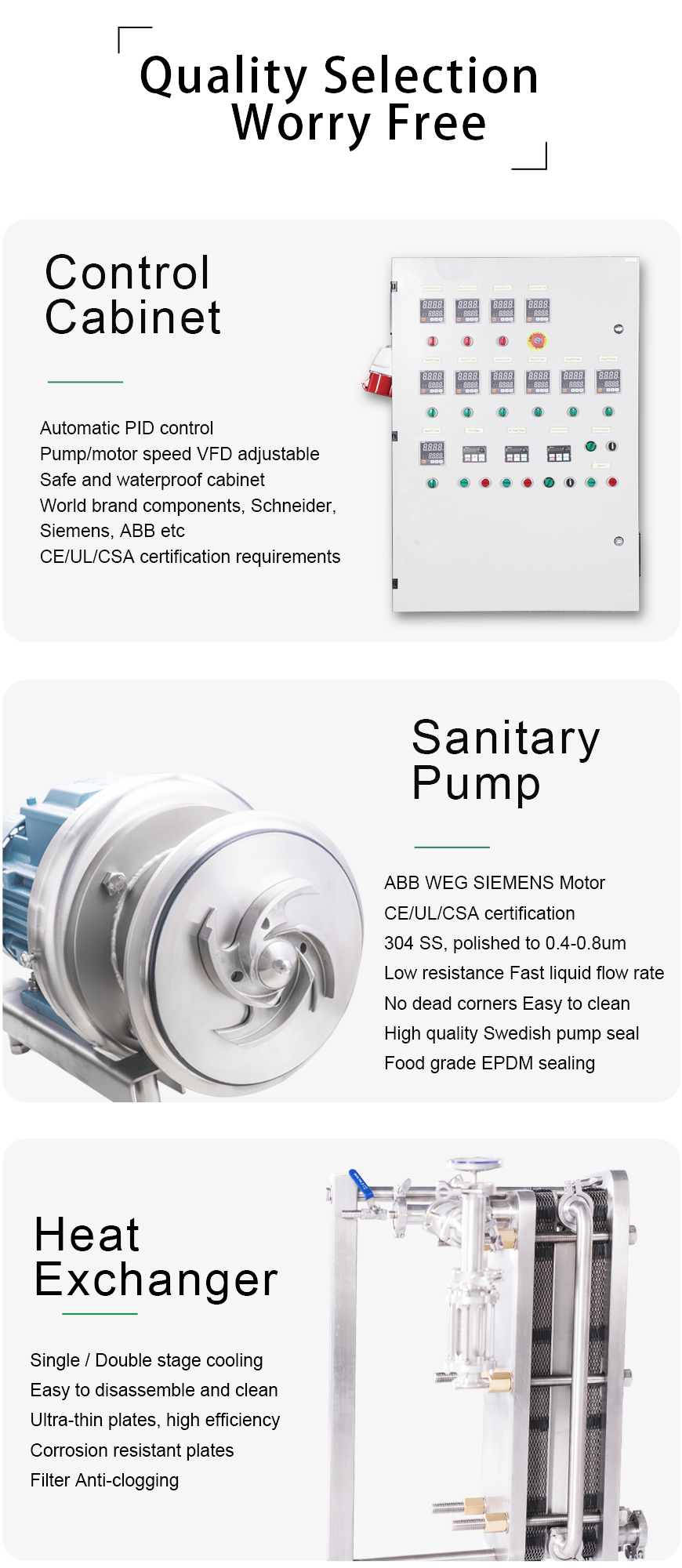

| Pump | 3M3 | ABB, Sanitary SUS304, VFD control | ||

| Pipe and fittings | As design | completely SS304, Work Platform is included | ||

| 3 | Fermentation unit | Fermenter | 600L or 1200L foroption | Dimple cooling jacket on cone and bottom |

| Side manway or top manway for option | ||||

| 60 degree cone bottom | ||||

| Tri clamp CIP ball | ||||

| Perlick style full sanitary sampling valve | ||||

| Carbonation port and level tube for special request | ||||

| 4 | Filtration unit(optional) | Plate-frame Filter | Max Flow: 1.5T/h | Power: 1.1kw |

| Cloth type, 10 layer | ||||

| Different material will be different for the flow | ||||

| 5 | Bright beer tank | Bright beer tank | 600L or 1200L foroption | Dimple cooling jacket on cone and bottom |

| Level tube for checking | ||||

| Tri clamp CIP ball | ||||

| Top manway or Side manway for option | ||||

| Perlick style full sanitary sampling valve | ||||

| Carbonation port with tri clmap carbonation stone | ||||

| 6 | Glycol Chilling Unit | Glycol Water Tank | 1200L | Insulated conical top and sloped bottom |

| Chiller | 8HPx1PCS | Cooling Capacity: 15400Kcal/8HP | ||

| Installed Power:7.6kw | ||||

| Refrigerant: Freon R404A ,R410A | ||||

| Noise:70-80db | ||||

| Coperland compressor | ||||

| PPR pipe | As designed | Solenoid valves for glycol inlet to tanks are included | ||

| Glycol water pump | 3M3 | Sanitary SUS304, VFD control | ||

| 7 | Control unit | Brewing and fermetation process Controlling | Floor type | PLC control with touch screen for special |

| PC or mobile remote control for special request | ||||

| 8 | CIP | Caustic Tank | 100L | electric heating element inside, With bimetal thermometer |

| Sterilization Tank | 100L | H2O2 | ||

| Pump | 3M3 | Sanitory, VFD control | ||

| 9 | Keg cleaning | 2 head | 20-30kegs/hr | Heating: Electric, Power: 15kw |

| 10 | Keg filling | A coupler | Manual | Coupler for filling beer |

| 11 | Bottling line | 4 head | 160-180 bottles/hr | Manual |

| 12 | Others | Option | Can be Customized | Auger System |

| Grain Case | ||||

| Grist Hydrator | ||||

| Piping flow panel for Brewhouse | ||||

| Brewhouse Separate PLC Controller | ||||