| General Specification for 30HL Brewery Equipment | ||||

| No. | Name | Components | Capacity | Parameter |

| 1 | Grain Milling Unit | Rolling Miller | 1000~1200kg/hr | Double roller Speed differential |

| Flexible Auger | 2500-3000kg/hr | Stainless steel screw PVC pipe |

||

| Grist Silo | 18HL | Milled malt holding, SUS304 | ||

| 2 | Brewhouse Unit | Mash tun | 30HL | Steam jacket on bottom and side Agitator inside Wort hydrator mounted top of mash tun |

| Lauter tun | 30HL | Grain rake with VFD Laser cutting V-wire False Bottom Easyclean and detachable sparging spray ring Multihole wort collect ring,Anti-rinser at the bottom |

||

| Kettle Tun | 30HL | Steam Jacket on bottom and side Steam vent with condensate ring for kettle stack |

||

| Whirlpool Tun | 30HL | Wort whirlpool, Tangential whirlpool inlet with reducing port |

||

| Hot water tank | 60HL | Hot water recycle from CLT and supply for mashing, sparging, cleaning | ||

| Heat exchanger | 30M2 | SUS304 plate, Single stage for cold water | ||

| Yeast Feeder | 50L | Inline yeast pitching for fermentable wort | ||

| Compelete Pipes & Fittings, Pumps | Pumps 10M3/H * 4sets, Non-slip Work Platform, Sanitary Piping, valves, Water Mixing Station, Wort Cooling Station Wort Aeration Station |

|||

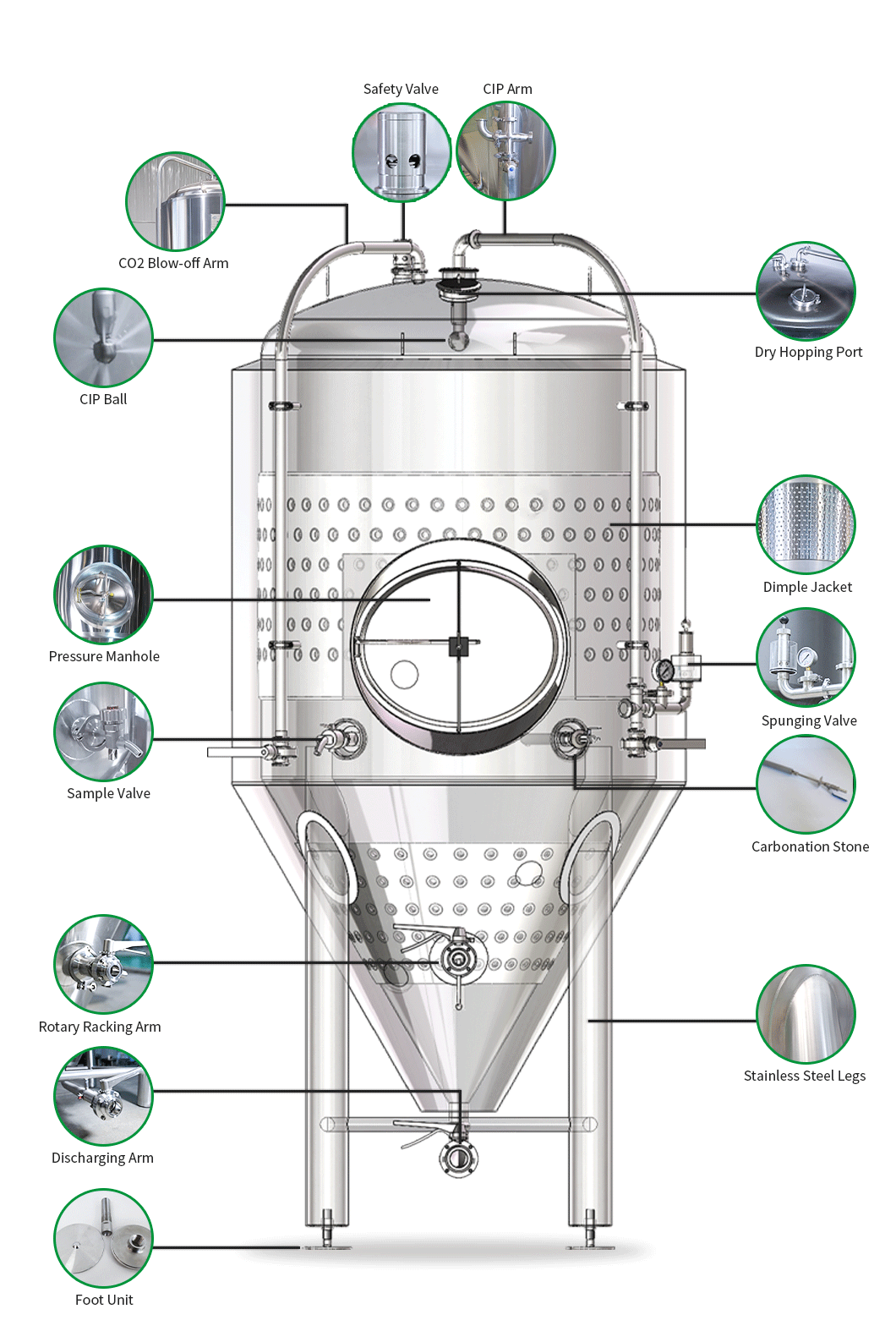

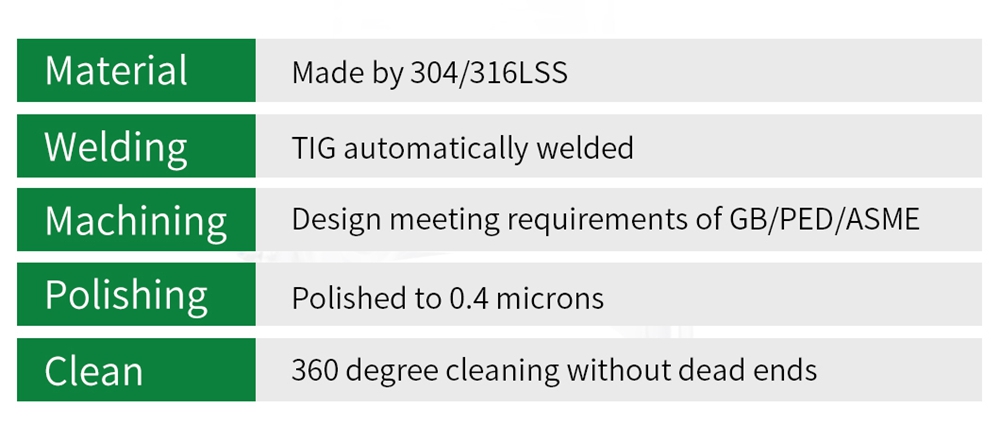

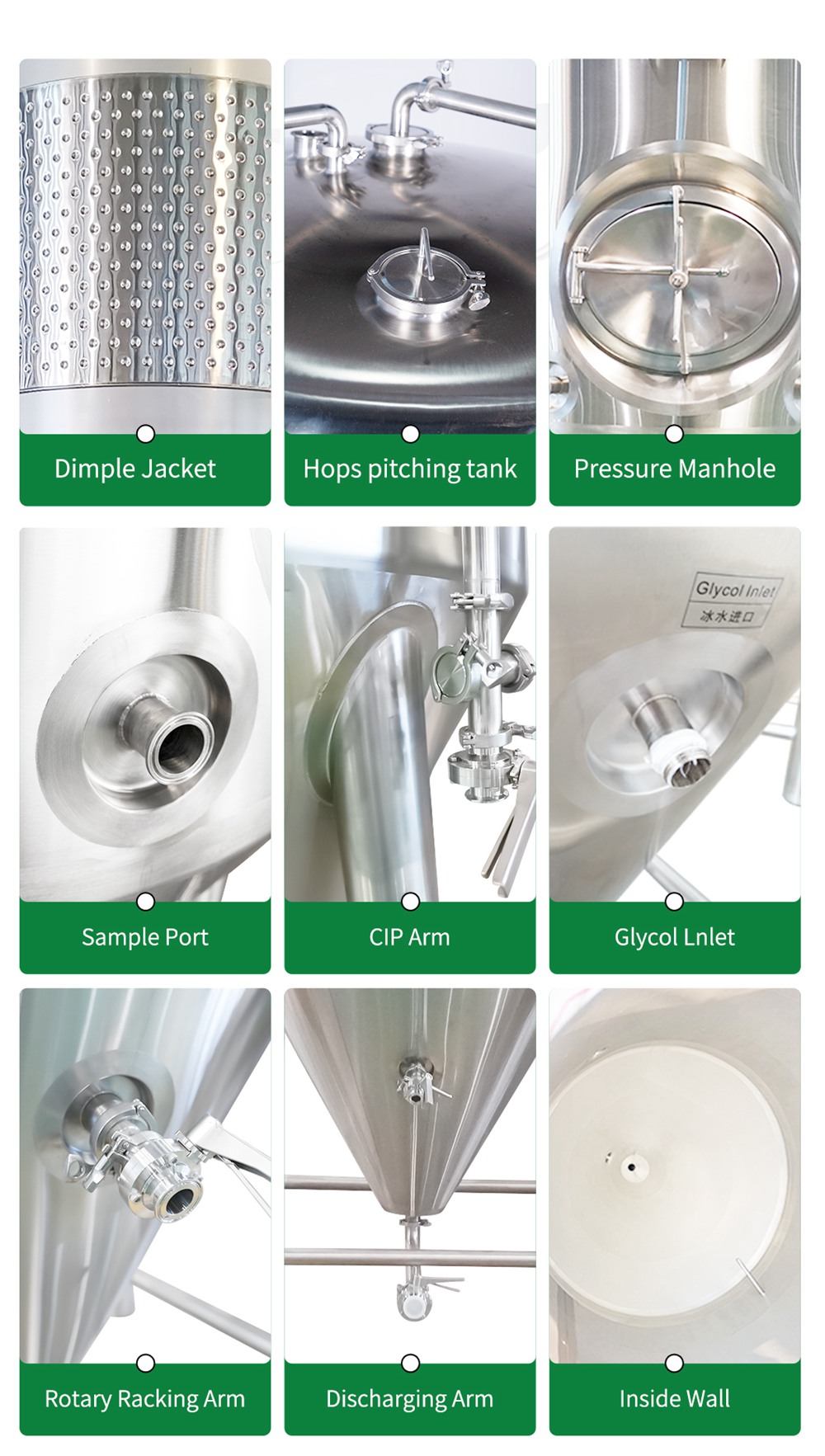

| 3 | Fermentation unit | Fermenter | 30HL or 60HL or 90HL or 120HL | Glyco cooling jacket Conical Bottom with 60° Side or top manway CIP arm and CO2 blow off arm Mechanical relief valve Shockproof pressure gauge Rotating racking arm Dry hopping port |

| Bright beer tank | 30HL or 60HL or 90HL or 120HL | Glyco cooling jacket Side or top manway CIP arm Mechanical relief valve Shockproof pressure gauge Carbonation stone Sight level |

||

| 4 | Filtration unit(optional) | Kieselguhr Filter | 1500kg/hr | Pressured candle type DE filter |

| 5 | Glycol Chilling Unit | Glycol Water Tank | 30HL | Insulated conical top and sloped bottom |

| Cold Water Tank | 60HL | Cold water supply for wort cooling | ||

| Chiller | 12HP x 2PCS | Cooling Capacity/Chiller: 18000W/15500Kcal/h | ||

| 6 | Control unit | Brewhouse controlling | PLC control with touch screen for special | |

| Fermentation Controling | PLC control with touch screen for special | |||

| 7 | CIP | Caustic Tank | 300L | electric heating element inside, 12KW |

| Sterilization Tank | 300L | |||

| Transfer&Control | 3M3/Hr Pump, VFD Control | |||

| 8 | Others | Option | 2-Station Keg Filler | |

| 2-Station 3-Tank Auto Keg Rinser | ||||

| Automatic Bottling Line [14-12-4 heads] | ||||

| 1500kg/hr Candle DE Filter | ||||

| 800L Oil-free Air Compressor | ||||

| 2000L/Hr RO Water system | ||||

| 300kg/hr Steam Boiler | ||||