Meet the Tiantai 1000 L Syrup Equipment—a high-quality stainless-steel system engineered for efficiency, hygiene, and versatility in beverage production, whether used for syrup formulations, brewing, distilling, or fermentation. Drawing from Tiantai’s extensive 24+ years of expertise in designing turnkey brewery and distillery systems, this 1000 L modular setup is customizable, robust, and backed by global support.

Key Features & Specifications

1. Capacity & Materials

Main tank capacity: 1000 L working volume with an additional ≥25% headspace

Construction: Inner tank crafted from food-grade stainless steel (SUS304 or SUS316L)

Wall Thickness: Typically, 2–3 mm for inner and outer shells; thicker insulation ranging from 60–80 mm.

2. Thermal Control & Insulation

Features dimpled glycol/steam jackets on sides and cone bottom, facilitating efficient heating/cooling processes

Rigorous testing protocols in place (jacket: 5 bar/1 hour; shell: 4 bar/1 hour; extended water tests up to 48 hours) .

Insulation: Often composed of rock wool or polyurethane (PU) foam, typically 80 mm thick, optimizing temperature control.

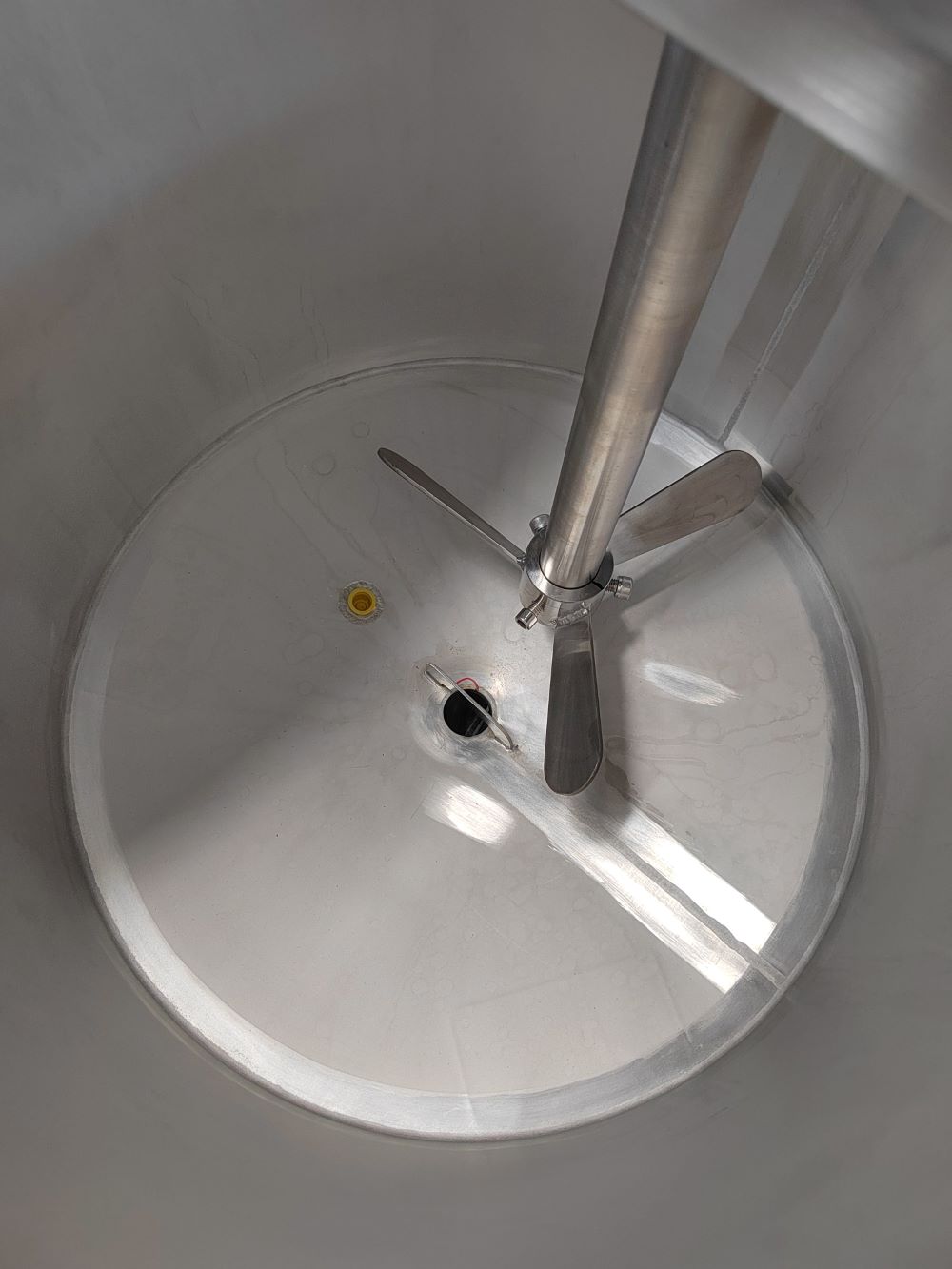

3. Sanitary Design & Finishing

Interior polished to 0.2–0.4 µm finish, ensuring sanitary conditions and minimizing dead zones.

Surface treatments include pickling, passivation, and optional mirror finishes like 8K gloss.

Welding: 100% TIG with argon shielding ensures seamless joints

4. Process Integration & Controls

Equipped with CIP spray balls, side manways, sampling ports, pressure-relief valves, and temperature sensors (PT100/thermowell) for full process control.

Optional PLC and PID control systems available, enabling semi- or fully automated process regulation.

5. Support & Compliance

Backed by a 5-year warranty on key components.

Certifications include ISO9001, CE, PED, ASME design validation, and factory audit approvals.

Advantages of Choosing the Tiantai 1000 L System

- Comprehensive Turnkey Capabilities: Tiantai offers full-system solutions—from mash tuns to distillation stills and spirit tanks—enabling integrated production setups for syrup, spirits, brews, or fermented beverages.

- Premium Build & Durability: Using top-grade materials, meticulous welding, and precision polishing, this system delivers both longevity and compliance with food safety standards.

- Versatility & Customization:The tank supports multiple heating modes (steam, electric, direct fire), various insulation options, and can be tailored with copper accents, custom branding, instrumentation, or layout configurations.

- Global Reliability & After-sales Support: Tiantai’s global footprint—including serviced installations across Europe, North America, and Asia—ensures strong local presence and prompt technical support.

- Excellent Value Proposition: Factory-direct pricing, coupled with high build quality and extensive warranty, make this equipment highly competitive for commercial ventures.

Real-World Insights

Several operators on brewing and distilling forums report positive experiences with Tiantai equipment:

“I’ve bought from them too… mine is top notch… they’re improving big time.”

— Fine Brewing System Owner Reddit

“I have a Tiantai system as well… I have loved it so far… customer service has been good.”

— Positive user review after 1.5 years Reddit

That said, a few advise ensuring compliance for control panels (UL/CSA certifications) and customizing to site standards:

“Make sure you also specify that you need your control panels to be code… you’ll probably still have to do a little rewiring.”

— Satisfied buyer who customized electronics Reddit

Comprehensive System Breakdown

| Component | Description & Benefits |

| Main Tank (1000 L) | Robust, insulated stainless steel structure with sanitary finish and options for copper |

| Heating / Cooling Jackets | Efficient thermal management with dimpled plates and rigorous pressure testing |

| Instrumentation | CIP system, manways, pressure/temperature sensors, sampling—all hygienically designed |

| Process Controls | Available automation (PLC/PID) or manual control tailored to your operational needs |

| Support & Compliance | Comprehensive warranties, global service, and international certifications |

Applications Across Industries

This 1000 Liter Tiantai system fits a wide range of applications, including:

Syrup Manufacturing – Precise temperature control for clarity and stability.

Craft Distilleries – Compatible with hybrid distillation setups for gin, vodka, brandy.

Micro-Wineries & Brewpubs – Ideal for batch fermentation with strict hygiene needs.

Hard Seltzer/Cider Production – Equipped for pressurized fermentation and cold stabilization.

Tiantai 1000 Liter Syrup Equipment is a top-tier, versatile, and customizable solution that blends excellent build quality with operational flexibility. Whether you’re launching a craft distillery, expanding a microbrewery, or scaling a syrup production line, Tiantai’s 1000 Liter system delivers precision engineering, efficiency, and solid global support.

Edited By Daisy Cai

Email: [email protected]