Non-alcoholic beers are no longer just an add-on, they’ve become an essential part of the core lineup. More and more customers ask TIANTAI Non-Alcoholic Beer Brewing System–Engineering the Future of Flavor Without Alcohol.

1.Introduction: The Rise of Non-Alcoholic Beer

The global beer market is undergoing a quiet revolution. While traditional beer consumption is stabilizing or even declining in some regions, non-alcoholic and low-alcohol beer (≤0.5% ABV) is one of the fastest-growing segments in the beverage industry. Driven by health awareness, lifestyle changes, stricter drinking-and-driving laws, and demand for functional beverages, consumers are increasingly seeking beer flavor without alcohol.

However, producing high-quality non-alcoholic beer is far more complex than simply “removing alcohol.” It requires precise process control, specialized equipment, and deep brewing know-how to preserve aroma, mouthfeel, and balance.

TIANTAI, with decades of experience in brewing and fermentation equipment, has developed advanced non-alcoholic beer brewing systems designed for craft breweries, regional producers, and industrial-scale operations—delivering authentic beer character with minimal or zero alcohol.

2.Understanding Non-Alcoholic Beer: Technical Challenges

Non-alcoholic beer production presents several key challenges:

–Flavor Loss

Alcohol acts as a carrier for aroma compounds. Removing or limiting alcohol often strips away esters, hop oils, and body.

–Microbiological Stability

Lower alcohol levels reduce beer’s natural microbial protection.

–Process Complexity

Brewing must carefully balance yeast activity, sugar conversion, and thermal stress.

–Regulatory Compliance

Alcohol thresholds vary by country (0.0%, 0.05%, or 0.5% ABV).

TIANTAI’s non-alcoholic beer systems are designed to address these challenges through multiple production pathways, allowing brewers to choose the most suitable method for their market and brand strategy.

3.TIANTAI Non-Alcoholic Beer Production Approaches

TIANTAI supports three main technical routes for non-alcoholic beer production, each with dedicated system configurations.

3.1 Limited Fermentation Brewing (Biological Method)

Concept: Alcohol formation is minimized during fermentation by controlling yeast behavior and wort composition.

Key Techniques:

Special low-attenuation yeast strains→Low fermentable sugar wort design → Low-temperature fermentation (8–12°C) → Early fermentation arrest

TIANTAI System Design Features:

Precision mash temperature control (multi-step infusion) → Highly accurate wort oxygenation system → Fermenters with advanced glycol zoning for tight temperature control → Automated fermentation stop logic (cooling + pressure control)

Advantages:

Natural brewing process → Lower investment cost →Suitable for craft and small-scale breweries

Limitations:

Alcohol typically around 0.3–0.5% ABV →Flavor profile requires careful recipe development

3.2 Dealcoholization After Fermentation (Physical Removal)

Concept:

Beer is brewed normally, then alcohol is selectively removed while preserving flavor compounds.

a) Vacuum Distillation System

TIANTAI integrates low-temperature vacuum evaporation systems, allowing alcohol removal at temperatures as low as 35–45°C, minimizing thermal damage.

System Components:

Vacuum evaporation column

Aroma recovery unit

Condensate alcohol separator

CIP-integrated closed-loop design

Advantages:

Full beer flavor development before alcohol removal

Suitable for premium non-alcoholic beer

b) Membrane Filtration (Optional Integration)

For advanced projects, TIANTAI can integrate:

Reverse osmosis (RO)

Nanofiltration (NF)

These systems separate alcohol and water from beer, then reconstitute the product.

Advantages:

Excellent flavor retention → Precise ABV control (down to 0.0%)

Considerations:

Higher capital investment→ Requires skilled operation’

3.3 Hybrid Brewing Solutions (TIANTAI Specialty)

TIANTAI’s strength lies in hybrid system design, combining:

Controlled fermentation

Gentle dealcoholization

Aroma recovery and reintegration

This approach allows breweries to: Optimize flavor → Reduce thermal stress→Improve energy efficiency

4.TIANTAI Non-Alcoholic Beer Brewing System Configuration

A typical TIANTAI non-alcoholic beer brewhouse and cellar includes:

4.1 Brewhouse Section

Malt handling & milling system

Mash tun with precise temperature ramping

Lauter tun with optimized false bottom design

Kettle with internal calandria (energy-efficient boiling)

Whirlpool for trub separation

4.2Cold Side & Fermentation

Plate heat exchanger (high-accuracy wort cooling)

Yeast propagation system

Cylindroconical fermenters (SS304 / SS316L)

Multi-zone glycol cooling jackets

Automated pressure & temperature control

4.3 Dealcoholization Module (Optional)

Vacuum distillation unit

Aroma recovery column

Alcohol collection tank

4.4 Post-Processing

Beer stabilization (pasteurizer or sterile filtration)

Carbonation system

Bright beer tanks

Packaging line integration (bottle / can / keg)

5. Automation & Control System

TIANTAI non-alcoholic beer systems are equipped with PLC + HMI automation, enabling:

Recipe management

Fermentation curve tracking

Alcohol level monitoring

CIP process automation

Remote troubleshooting capability

This ensures repeatability, consistency, and regulatory compliance, which are critical in non-alcoholic beer production.

6.Flavor Preservation: A Core Design Philosophy

TIANTAI places strong emphasis on sensory quality, incorporating:

Low-shear pumps

Gentle heat transfer surfaces

CO₂ blanketing throughout the process

Closed-loop aroma recovery

The result is a non-alcoholic beer with:

Authentic malt backbone

Clean bitterness

Balanced mouthfeel

Fresh hop aroma

7.Energy Efficiency & Sustainability

Non-alcoholic beer production can be energy-intensive. TIANTAI addresses this with:

Internal calandria kettles (lower steam consumption)

Heat recovery from wort cooling and dealcoholization

Optimized CIP water reuse systems

Insulated vessels to minimize thermal loss

These measures reduce operating costs and align with global sustainability goals.

8.Applications & Target Customers

TIANTAI non-alcoholic beer brewing systems are ideal for:

Craft breweries expanding product portfolios

Industrial breweries entering the 0.0% beer market

Beverage companies producing functional or wellness drinks

Export-focused brands needing strict ABV compliance

System capacities range from 5 HL pilot systems to 200 HL industrial brewhouses.

9.Why Choose TIANTAI?

Proven experience in brewing & fermentation equipment

Flexible system design tailored to local regulations

Strong focus on flavor integrity

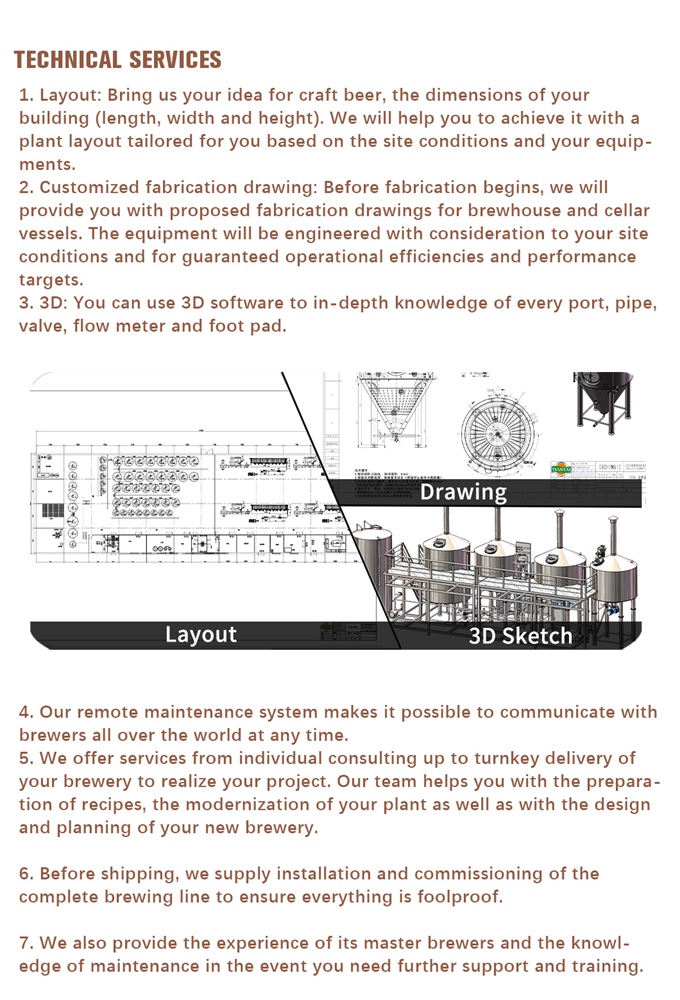

Full turnkey solutions (design → manufacture → installation)

Global project experience

TIANTAI does not just supply equipment — we engineer complete non-alcoholic beer solutions.

Brewing Without Alcohol, Not Without Character

Non-alcoholic beer is no longer a compromise. With the right technology and process design, it can deliver complexity, balance, and true beer identity.

The TIANTAI Non-Alcoholic Beer Brewing System empowers brewers to confidently enter this fast-growing market, offering flexibility, precision, and scalability — all while preserving what matters most: flavor.

If you are planning a non-alcoholic beer project, TIANTAI is ready to support you from concept to commercial success.

Edited By Daisy: [email protected]