Vertical Brite Beer Tank vs Horizontal Brite Beer Tank, different Design Concepts and How to Choose the Right One for Your Brewery. In a modern brewery, the brite beer tank (BBT) plays a critical role between fermentation and packaging. It is where beer is clarified, carbonated, stabilized, and held under pressure before bottling, canning, or kegging. While brewers often focus on fermentation tanks and brewhouse design, the design of the brite tank can significantly influence beer quality, operational efficiency, and overall brewery layout.

Among the most common configurations, Vertical Brite Beer Tanks and Horizontal Brite Beer Tanks stand out as two fundamentally different design philosophies. Each has its own advantages, limitations, and ideal application scenarios.

This article explores both designs in depth and helps you decide which brite tank configuration best suits your brewery.

1.What Is a Brite Beer Tank?

A brite beer tank is a pressure-rated stainless steel vessel used to:

Clarify beer after fermentation→ Carbonate beer (force carbonation) → Hold finished beer before packaging →Maintain beer quality under cold, sanitary conditions

Typical brite tanks include:

| ♦Internal pressure rating (usually 2–3 bar) | ♦Cooling jacket(s) |

| ♦Carbonation stone | ♦CIP spray ball |

| ♦Pressure relief valve | ♦Sample valve and racking outlet |

The orientation of the tank—vertical or horizontal—affects how all these functions perform in real-world brewing operations.

2.Vertical Brite Beer Tank

Vertical brite beer tanks are tall, upright vessels, usually supported by legs or a skirt. They closely resemble vertical fermenters but are optimized for carbonation and storage rather than fermentation. They are the most widely used brite tank design worldwide, especially in commercial and craft breweries.

Key Advantages

2.1 Space Efficiency

Vertical brite tanks have a small footprint, making them ideal for breweries with limited floor space. In urban breweries or compact production facilities, vertical tanks allow higher capacity without expanding the building footprint.

2.2 Better CO₂ Stratification and Carbonation Control

Carbon dioxide naturally rises. In a vertical tank, this behavior supports:

More uniform carbonation→ Faster dissolution of CO₂→ Easier control of carbonation levels

Carbonation stones work especially efficiently in vertical tanks due to better liquid depth.

2.3 Easier Yeast and Sediment Management

Although brite tanks are not meant for active fermentation, some residual yeast and solids may still settle. The vertical design allows sediment to collect at the bottom cone or dish, making purging and cleaning easier.

2.4 Simplified CIP and Sanitation

Vertical geometry supports: Effective spray ball coverage→ Minimal shadow zones→ Shorter CIP cycles

This translates to lower water, chemical, and energy consumption over time.

2.5 Standardization and Scalability

Most equipment suppliers standardize vertical brite tanks. This means: Faster delivery→Lower cost per liter→Easier integration with automated systems→Limitations→Requires higher ceiling clearance→ May need platforms or catwalks for top access→ Less suitable for very low-ceiling buildings

3.Horizontal Brite Beer Tank

Horizontal brite beer tanks are laid on their side and supported by saddles. This design is less common for brite tanks but is sometimes used in low-height buildings or specific brewery layouts.

Key Advantages

3.1 Low Height Requirement

The most obvious advantage of horizontal brite tanks is their minimal height. They are ideal for: Basements→ Renovated industrial buildings→ Breweries with strict height limitations

3.2 Easy Visual Access

Valves, manways, and fittings are often positioned at ergonomic heights, allowing: Easier manual operation and Reduced need for ladders or platforms.

3.3 Suitable for Certain Lagering Applications

In some traditional brewing setups, horizontal tanks are favored for extended cold storage. The wide surface area can support stable temperature distribution during long holding periods.

Limitations

— Larger Footprint: Horizontal tanks occupy significantly more floor space. This can limit expansion and reduce the number of tanks you can install in the same area.

–Less Efficient Carbonation, Because of reduced liquid depth: CO₂ absorption is slower→Carbonation may be less uniform→ Longer carbonation times are often required

–More Complex CIP, Horizontal tanks are more challenging to clean: Spray coverage can be uneven→ Dead zones are more likely→ CIP cycles may be longer and more chemical-intensive

–Higher Customization Cost, Horizontal brite tanks are often custom-built, resulting in: Higher fabrication cost→ Longer delivery times→More complex installation

4.Vertical vs Horizontal: Direct Comparison

| Aspect | Vertical Brite Tank | Horizontal Brite Tank |

| Floor space | Small footprint | Large footprint |

| Ceiling height | Requires higher ceiling | Very low height required |

| Carbonation efficiency | Excellent | Moderate |

| CIP effectiveness | High | Medium |

| Installation cost | Lower (standardized) | Higher (custom) |

| Expansion flexibility | Easy | Limited |

| Common usage | Craft & industrial breweries | Low-ceiling or niche setups |

5.Which One Should You Choose?

Choose a Vertical Brite Beer Tank If:

- You want efficient carbonation

- Floor space is limited but ceiling height is available

- You plan to scale production in the future

- You want standardized, cost-effective equipment

- Automation and CIP efficiency matter

This is the default and recommended choice for most modern breweries.

Choose a Horizontal Brite Beer Tank If:

- Building height is severely restricted

- You are retrofitting an existing facility

- You prioritize manual access and visual inspection

- Your production scale is fixed and unlikely to expand

Horizontal brite tanks are often a solution to architectural constraints, not a first-choice design.

The choice between vertical and horizontal brite beer tanks is not just about aesthetics—it directly impacts beer quality, operational efficiency, cleaning performance, and long-term brewery growth.

In most commercial brewing environments, vertical brite tanks clearly outperform horizontal designs in terms of carbonation efficiency, space utilization, and scalability. Horizontal brite tanks, while useful in specific situations, are best viewed as a practical compromise when height limitations cannot be avoided. When designing or expanding a brewery, always evaluate:

Building dimensions, Production targets, Carbonation requirements, Cleaning and labor efficiency

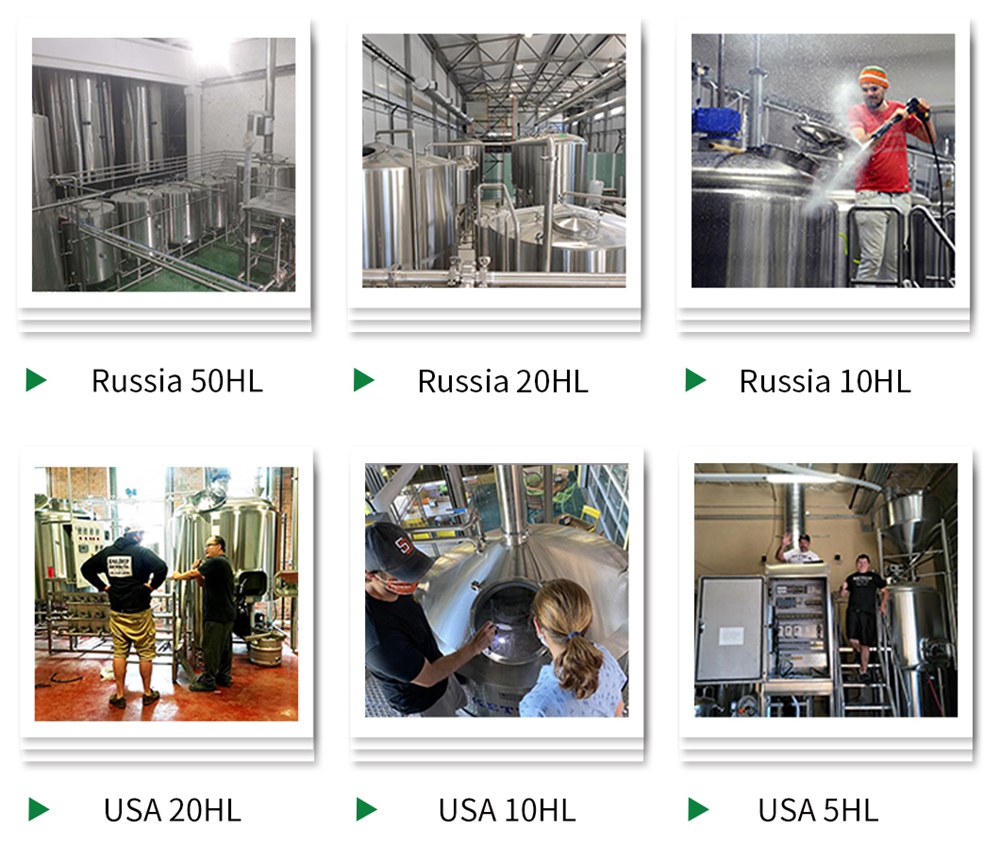

Future expansion plans. A well-chosen brite tank design will quietly but reliably support every great beer you send to the market. If you are interesting in TIANTAI brite beer tank, fermentation tanks, please feel free to ask us.

Edited By Daisy : [email protected]