Kegging beer is one of the most important steps in a modern brewery’s production process. Whether you are a small craft brewery, a regional production brewery, or a contract brewer, the way you handle kegging has a direct impact on beer quality, shelf life, labor efficiency, and overall profitability.

Unlike bottling or canning, kegging is often perceived as “simpler.” However, professional kegging at a brewery requires a well-designed system of equipment that ensures sanitation, oxygen control, carbonation accuracy, and consistent filling. Poor kegging practices can quickly undo months of careful brewing work.

In this in-depth blog, we will walk through all the essential equipment you need to keg beer at a brewery, explain why each piece matters, and discuss best practices for building an efficient, scalable kegging operation. This guide is written for professional brewers and brewery owners and goes far beyond basic homebrewing setups.

1. Beer Kegs: The Foundation of the System

Beer kegs are the vessels that store, transport, and dispense your finished beer. In a brewery environment, they must be durable, standardized, and easy to clean.

Common Types of Beer Kegs

|

Stainless Steel Kegs (Most Common)

|

▪Sizes: 20L, 30L, 50L (EU), 1/2 bbl, 1/6 bbl (US)

▪Long lifespan (20–30 years) ▪Fully recyclable ▪Excellent pressure resistance and hygiene |

|

Slim Kegs |

▪Same volume as standard kegs but taller and narrower

▪Useful for space optimization |

|

One-Way (Disposable) Kegs |

▪Used for export or long-distance logistics

▪No return logistics required ▪Higher per-unit cost |

Why Keg Quality Matters?

TIANTAI answer: Low-quality kegs can: Leak CO₂ and beer, Harbor microorganisms in damaged interiors, Fail under pressure, Increase product loss and safety risks.

Professional breweries almost always rely on certified stainless steel kegs that meet international pressure vessel standards.

2. Keg Cleaning and Washing System (Non-Negotiable)

If there is one piece of equipment you should never compromise on, it is the keg washer. Kegs are reused hundreds of times, and every refill must start with a perfectly clean and sanitized container.

Types of Keg Washers

| Manual or Semi-Automatic Keg Washers | 1–2 heads |

| Lower upfront cost | |

| Higher labor input | |

| Suitable for small breweries | |

| Automatic Keg Washers | 2–6 heads or more |

| Fully automated cleaning cycles | |

| Higher throughput | |

| Consistent sanitation | |

| Rotary or High-Speed Keg Washers | Large-scale production |

| Integrated with filling lines | |

| Minimal labor |

What’s the Keg Washing Steps?

Typical Keg Washing Steps, it is Pre-rinse (removes residual beer) → Caustic wash (removes organic material) → Intermediate rinse → Acid wash (removes beer stone) → Final rinse → Steam or chemical sanitization → CO₂ purge → Finished

A well-designed keg washer should ensures: Microbiological stability, Reduced off-flavors, Longer shelf life, Compliance with food safety regulations.

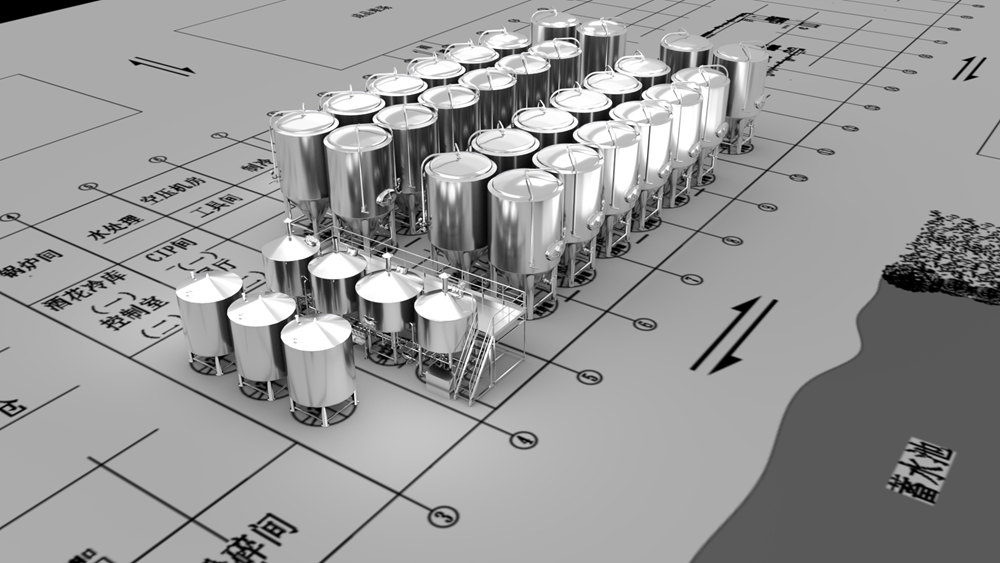

3. Bright Beer Tanks (BBTs)

Bright beer tanks are where beer is held after fermentation and filtration and before packaging. They play a critical role in kegging operations.

What’s the Functions of Bright Beer Tanks?

It can be Carbonation adjustment, Clarification and polishing, Cold storage, Stable pressure environment for filling

The Key Features for Brite Tank are Pressure-rated stainless steel construction, Cooling jackets, Carbonation stone, CIP spray ball, Sample valve, Level indicators, Pressure and safety valves.

Most breweries keg directly from bright beer tanks to maintain closed, oxygen-free transfer, which is essential for beer freshness.

4. CO₂ and Gas Management System

Carbon dioxide (CO₂) is essential throughout the kegging process. Without proper gas control, beer quality will suffer.

Core CO₂ Equipment, including Bulk CO₂ tank or cylinder manifold, Pressure regulators, Gas distribution lines, Gas shut-off valves, Check valves (to prevent backflow).

Why Gas Control Is Critical?

Purging oxygen from kegs, Carbonating beer, Maintaining tank pressure during filling, Preventing foaming.

Many breweries also use nitrogen (N₂) or beer gas (CO₂/N₂ blends) for certain styles like stouts or nitro beers.

5. Keg Filling Equipment

The actual filling of beer into kegs must be precise, gentle, and oxygen-free.

Common Keg Filling Methods: Gravity Filling (rare in modern breweries) and Pressure Filling (Most Common).

For Pressure Filling, Keg is pressurized with CO₂, Beer is pushed in under equal pressure, Minimal foaming and oxygen pickup.

Keg Filling Configurations: Standalone keg fillers, Integrated keg washer + filler systems, Fully automated kegging lines.

Advanced systems include: Automatic fill level detection, Weight-based filling, Foam detection, Inline oxygen monitoring.

6. Beer Transfer Lines and Fittings

Beer never touches only one piece of equipment—it flows through a network of hoses, pipes, and fittings.

Essential Components, including Food-grade hoses (EPDM, silicone, or PTFE-lined), Stainless steel hard piping, Tri-clamp fittings, Butterfly or diaphragm valves, Flow meters (optional)

Best Practices: Keep hose lengths as short as possible, Use dedicated hoses for beer only, Perform CIP after every kegging run, Replace hoses regularly.

Even the best kegging system can be ruined by poorly maintained hoses.

7. Cleaning-In-Place (CIP) System

A CIP system allows you to clean tanks, pipes, and fillers without disassembly.

Typical CIP Components, including CIP tank(s) for caustic and acid, Heating system, CIP pump, Return lines, Control valves.

CIP systems ensure: Consistent cleaning, Reduced labor, Improved safety, Better hygiene control.

For breweries kegging regularly, a dedicated CIP system is essential.

8. Oxygen Control and Quality Monitoring

Oxygen is the enemy of finished beer. Even small amounts can dramatically reduce shelf life.

Oxygen Control Tools

CO₂ purging systems, including Dissolved oxygen (DO) meter, Inline oxygen analyzers, Closed-transfer connections.

Professional breweries aim for dissolved oxygen levels below 30 ppb during kegging.

9. Cold Storage and Logistics Equipment

Once beer is kegged, it must remain cold and protected.

Supporting Equipment, including Cold room or refrigerated warehouse, Pallet racks, Keg dollies and lifters, Forklifts or pallet jacks, Keg tracking systems (RFID or barcodes).

Proper cold storage ensures beer stability and reduces foam and pressure issues.

10. Safety and Compliance Equipment

Kegging involves pressure, chemicals, and heavy lifting.

Essential Safety Equipment, including Pressure relief valves, Safety cages for CO₂ tanks, PPE (gloves, goggles, aprons), Emergency gas detectors, Drainage systems.

Compliance with local food safety and workplace regulations is critical for brewery operations.

Kegging beer at a brewery is not just about filling containers—it is about process control, hygiene, and quality preservation. A professional kegging setup includes: High-quality stainless steel kegs, Reliable keg washers, Bright beer tanks, Gas management systems, Precision filling equipment, Robust CIP systems, Strict oxygen control.

Investing in the right equipment from the beginning saves money in the long run by reducing beer loss, labor costs, and quality issues.

Whether you are expanding an existing brewery or designing a new one, a well-planned kegging system will support consistent beer quality, improve operational efficiency, and help your brewery grow sustainably.

If you would like, we can help you to design a complete kegging line layout, recommend equipment based on brewery size and output, compare manual vs automatic kegging systems

Building an Efficient Kegging System is also very important at brewery. Just let me know how deep you want to go.

Edited By Daisy Cai

[email protected]