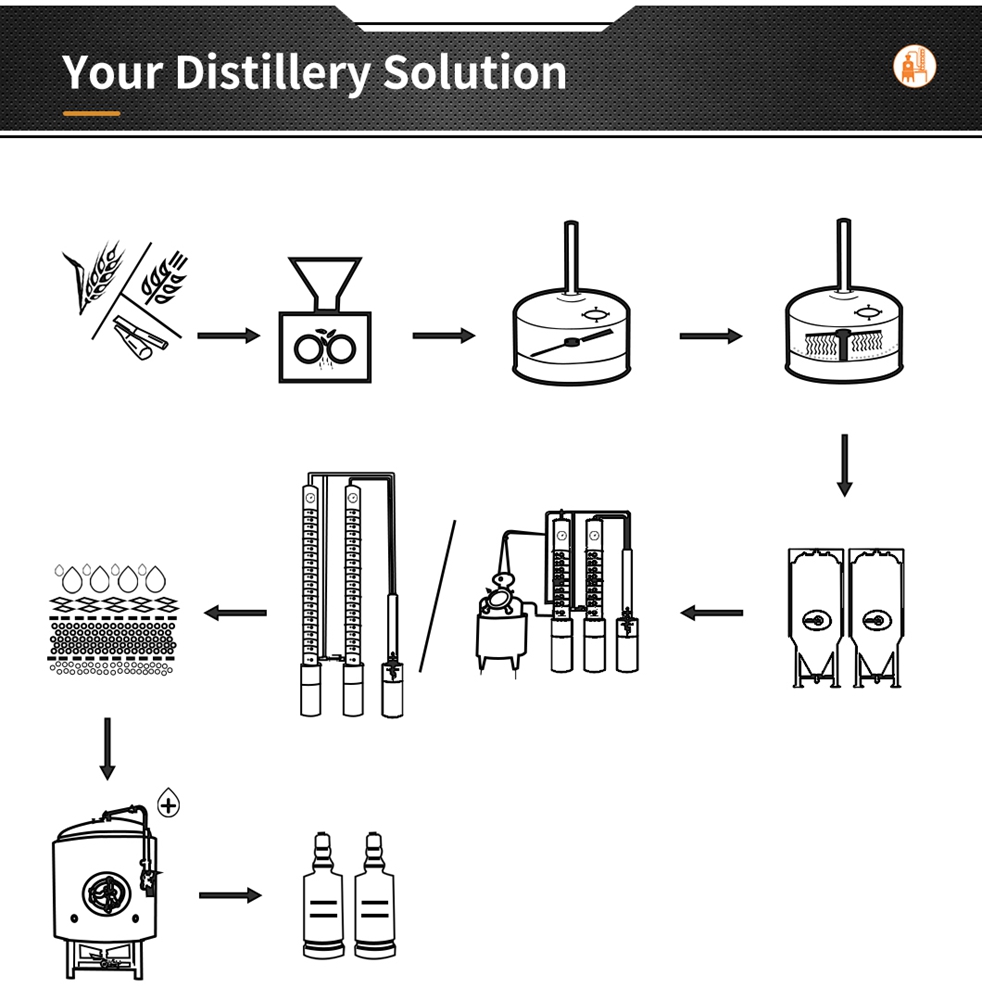

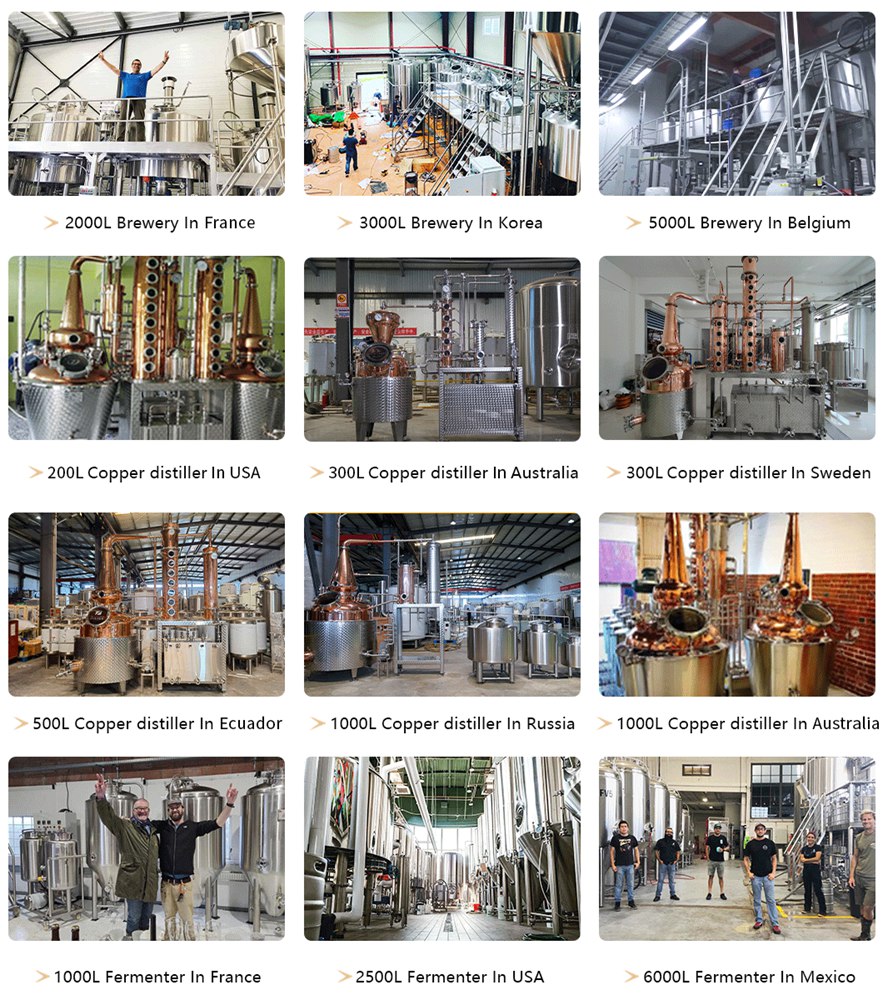

As the leader in beverage equipment, we wanted to bring you a new series of blogs that we think will be helpful for many startups, small distillery and craft brewery establishments that are thinking about getting into distilling craft spirits. Some of the initial questions we get at TIANTAI Equipment from those starting a distillery are about what we do and how our distillation equipment can help you be more profitable. We invite you to read through our blog series and hope that it makes the process of distilling alcohol a little bit more painless!

Recently there is a Russian customer who is looking for distillery system for Brandy at their winery. And they asked a question: Which Kind of Distillation System is Suitable for Distilling Brandy? So this blog helps you to learn more about Brandy, and the distillation system to still Brandy.

Let’s first understand what Brandy is.

Brandy, derived from the Dutch word brandewijn (“burnt wine”), is one of the oldest and most prestigious distilled spirits in the world. Traditionally produced by distilling wine or fermented fruit juice, brandy carries with it centuries of heritage, craftsmanship, and technical expertise. From the Cognac region in France to artisanal fruit brandies in Central Europe, the choice of distillation method plays a critical role in defining its flavor, aroma, and quality.

Selecting the right type of distillation is not only a matter of tradition but also of product design, market positioning, and operational efficiency. Unlike neutral spirits such as vodka—where the goal is high-purity alcohol with minimal flavor—brandy distillation aims to preserve and refine the delicate aromatic compounds derived from grapes or fruits. Thus, the choice between pot still distillation, column still distillation, or a hybrid method becomes central to the production philosophy.

This article explores in depth the distillation methods suitable for brandy, their advantages and disadvantages, and how modern producers balance tradition with innovation.

1. The Goals of Brandy Distillation

Before analyzing the different distillation technologies, it is crucial to understand the goals of distilling brandy:

Preserve Aromatic Complexity – Brandy derives its character from the grapes or fruits used. The distillation must retain esters, higher alcohols, and congeners that provide floral, fruity, and spicy notes.

Remove Harsh Compounds – Methanol, fusel oils, and excessive volatile acidity must be carefully separated during distillation.

Achieve Balance – Unlike neutral spirits, brandy is not distilled to very high ABV. Most brandies are collected between 60–72% ABV, allowing congeners to remain but still refining the spirit.

Enhance Maturation Potential – Distillation creates a spirit that will interact with oak casks during aging. A too-clean distillate lacks body for long aging, while a too-heavy one may taste harsh.

These goals explain why batch distillation using pot stills has historically been favored, but other technologies can also be applied depending on style.

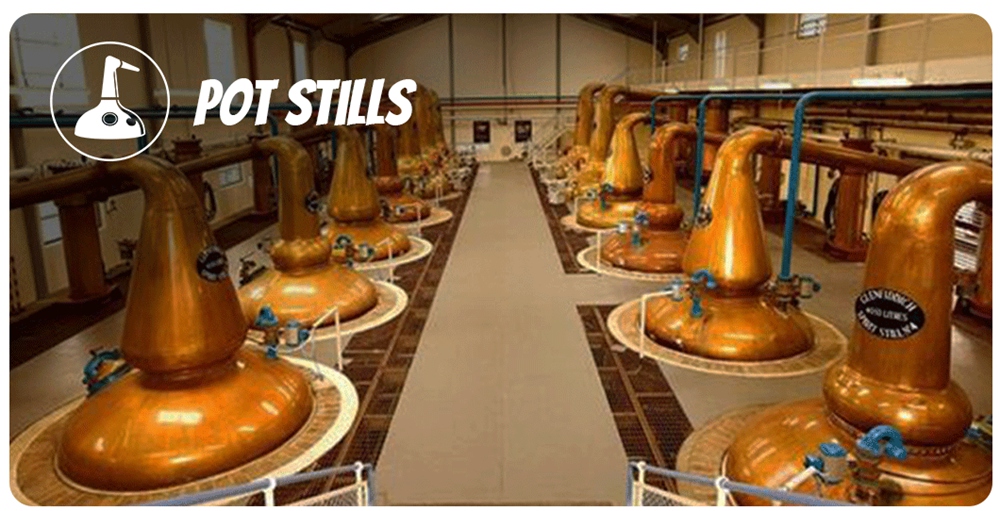

2. Traditional Method: Pot Still Distillation

2.1 Overview

The pot still is the oldest form of distillation and remains the most iconic for brandy. A pot still consists of a copper kettle where the wine or fruit mash is heated, a swan neck, and a condenser. Distillation occurs in batches, and the distiller makes precise cuts between heads, hearts, and tails.

For brandy, pot stills are typically made of copper, which plays a chemical role in removing sulfur compounds, enhancing smoothness, and enriching flavor.

2.2 Double Distillation

The Cognac method requires double distillation:

First distillation: Produces brouillis (~28–32% ABV).

Second distillation: Yields eau-de-vie (~68–72% ABV).

This two-stage process allows precise control over aroma retention and removal of unwanted fractions.

2.3 Advantages

Rich, complex flavor: Retains esters and congeners essential for brandy character.

Traditional authenticity: Required by law in Cognac and Armagnac.

Copper benefits: Improves smoothness and aroma quality.

Aging synergy: Produces a spirit with good body for maturation in oak barrels.

2.4 Limitations

Low efficiency: Batch process requires more time and energy.

Lower yield: Compared to column stills.

Labor-intensive: Requires skilled distillers to manage cuts.

Despite limitations, pot still distillation remains the gold standard for high-quality, premium brandy.

3. Alternative Method: Column Still Distillation

3.1 Overview

Column stills (also called continuous stills or Coffey stills) operate in a continuous process, with fermented wine fed into a series of perforated plates. Steam rises, stripping alcohol, and multiple rectification stages occur simultaneously.

This allows production of spirits at higher ABV (up to 95%), though lower-strength distillates can also be drawn depending on design.

3.2 Application in Brandy

Some industrial-scale brandy producers—particularly outside Europe—use column stills for efficiency and cost reduction. These are common in large-scale production in South America, South Africa, and parts of Asia.

3.3 Advantages

High efficiency: Continuous process saves energy and time.

Large capacity: Suitable for industrial-scale operations.

Flexibility: Can produce various distillate strengths.

Cost-effective: Lower labor and production costs.

3.4 Limitations

Loss of aromatic complexity: Higher rectification removes congeners, leading to a cleaner but less characterful spirit.

Lack of tradition: Not compliant with regulations in Cognac and Armagnac.

Maturation issues: A too-neutral spirit may not develop depth in aging.

Column still distillation is more suitable for value-oriented brandies, blending, or base spirits used in liqueurs, rather than premium artisanal expressions.

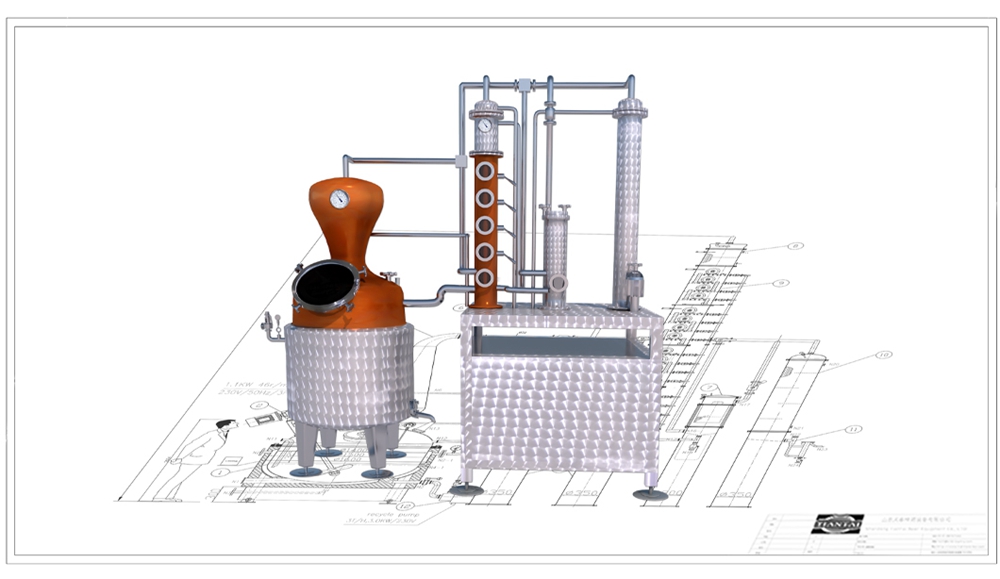

4. Hybrid Distillation: Bridging Tradition and Efficiency

4.1 What Is a Hybrid Still?

A hybrid still combines a pot still with a short rectifying column attached to the neck. The column may have 3–6 plates, allowing partial rectification while maintaining aromatic character.

4.2 Why Use Hybrid Stills for Brandy?

Hybrid stills offer flexibility:

The operator can bypass the column for traditional pot-style distillation.Or engage plates to refine the spirit more than a classic pot still. This is useful for craft distillers seeking balance between tradition and efficiency.

4.3 Advantages

Flavor preservation with some refinement.

Versatility: Can switch between brandy, gin, rum, or whiskey production.

Energy savings compared to pure pot still.

Customization: Producers can fine-tune aromatic retention.

4.4 Limitations

Not always accepted by traditional laws (e.g., Cognac AOC).

Learning curve for precise operation.

Expensive equipment compared to standard pot stills.

For modern distilleries outside strict regional regulations, hybrid stills represent a highly suitable option for brandy.

Distillation Methods for Brandy

| Feature | Pot Still Distillation | Column Still Distillation | Hybrid Still Distillation |

| Process Type | Batch (double distillation traditional) | Continuous | Batch or semi-continuous (flexible) |

| Alcohol Strength | 60–72% ABV | Up to 95% ABV (can adjust) | 65–80% ABV (depending on plates used) |

| Flavor Profile | Rich, complex, aromatic; retains congeners | Cleaner, lighter, sometimes neutral | Balanced: preserves aroma but more refined |

| Efficiency | Low – time & energy intensive | High – continuous and cost-effective | Medium – more efficient than pot, less than column |

| Tradition/Regulations | Required for Cognac, preferred for premium artisanal brandy | Rare in traditional brandy, common in mass production | Not allowed in Cognac/Armagnac AOC, but used in modern craft distilleries |

| Best Use | Premium brandy (Cognac, high-quality fruit brandy) | Large-scale, value or blending brandy | Craft brandy, experimental styles, versatile operations |

| Equipment Cost | Moderate to high | High (industrial-scale) | High (due to versatility and customization) |

| Maturation Suitability | Excellent – develops depth in oak | Weaker – lighter spirit may lack body for aging | Good – can tailor spirit for aging potential |

5. Regional Perspectives

5.1 Cognac (France)

Mandated by law: Copper pot stills with double distillation.

Strict tradition ensures consistent quality and heritage.

5.2 Armagnac (France)

Traditionally distilled in a continuous alembic still, a type of column still with fewer plates, producing richer, heavier spirits.

Shows how modified column technology can suit brandy styles.

5.3 Spain, South Africa, and South America

Use both pot stills and column stills.

Blends often combine characterful pot distillates with lighter column distillates to achieve balance and consistency.

5.4 Modern Craft Distilleries Worldwide

Increasing use of hybrid stills for flexibility.

Producers value the ability to adjust character and create unique brandy expressions.

6. Choosing the Right Distillation for Your Brandy Project

The choice of distillation method depends on:

Product Positioning

Premium artisanal brandy → Pot still distillation.

Mass-market brandy → Column still for efficiency.

Mid-tier/craft innovation → Hybrid still.

Raw Material Quality

High-quality grapes or fruit → Pot still to showcase aroma.

Bulk wine or surplus → Column still for neutral blending spirit.

Regulations

If producing under Cognac or Armagnac AOC → Must follow traditional methods.

If outside Europe → More flexibility.

Operational Goals

Small-scale craft → Pot or hybrid.

Industrial-scale → Column or combined system.

7. Future Trends in Brandy Distillation

Sustainability: Energy-efficient stills and waste-heat recovery systems.

Innovation: More hybrid stills with modular design.

Terroir-driven spirits: Small producers emphasizing pot still authenticity.

Globalization: Non-traditional regions experimenting with new methods.

Finally, Brandy is a spirit defined by its raw material and shaped by its distillation. The question of which distillation method is suitable for brandy does not have a single answer—it depends on tradition, style, and production goals.

For premium brandies such as Cognac, copper pot still double distillation remains the benchmark, delivering depth, complexity, and authenticity.

For large-scale, cost-effective production, column stills provide efficiency, though often at the expense of character.

For modern craft producers, hybrid stills offer flexibility, allowing the distiller to balance tradition with innovation.

Ultimately, the most suitable distillation method for brandy is the one that best aligns with the producer’s vision of flavor, heritage, and market positioning. Whether preserving centuries-old methods or embracing modern efficiency, distillation remains the heart of brandy craftsmanship. TIANTAI Company can customize any distillation system from mini 50 liters distill kit to commercial large distillery project. Welcome your proposal!

Edited By Daisy Cai

Email: [email protected]