More and more breweries are choosing to install distillery systems alongside their brewhouses in order to diversify their product portfolios. Spirits production allows breweries to maximize facility utilization, create higher-margin products, and offer customers a wider range of flavors and experiences.

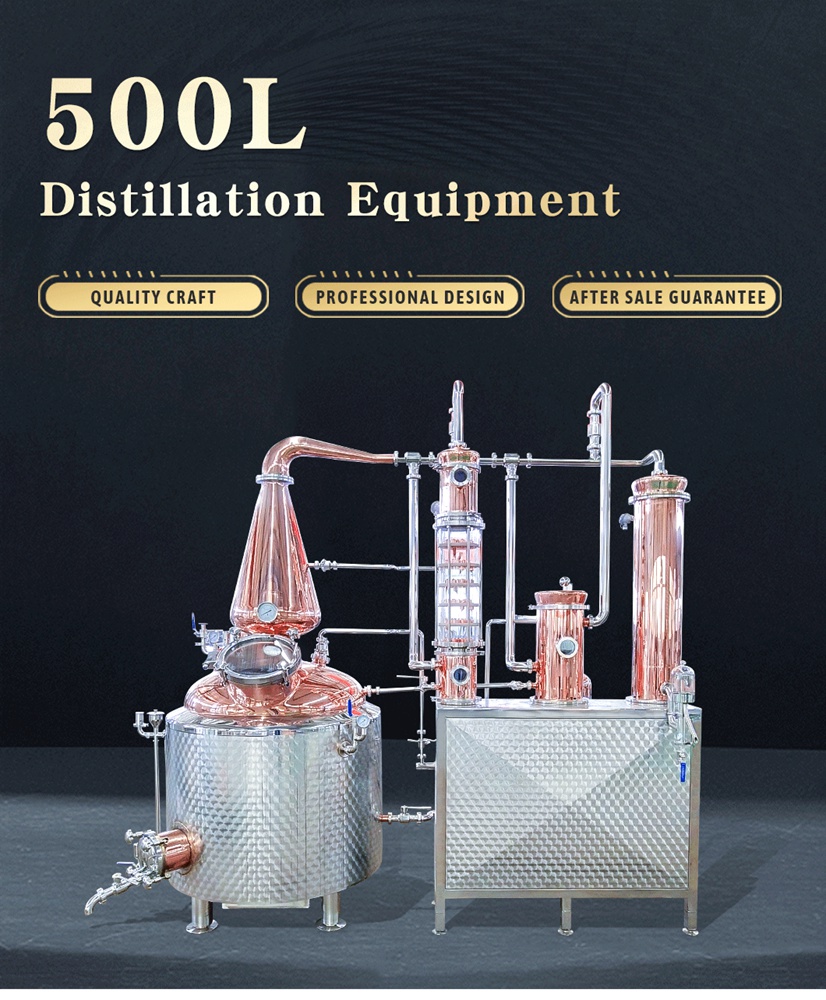

If you’ve decided to take up distilling—and you’re a whiskey enthusiast—there’s a good chance you’ve chosen to work with a pot still to produce the most authentic flavor profile possible. Pot stills have the oldest pedigree in the distilling world, and pot-stilled whiskies, rums, and brandies remain some of the most sought-after spirits on the planet.

That said, pot stills do come with certain limitations—especially when production efficiency and throughput are important considerations.

The Limitations of Pot Stills

A traditional pot still is not the most efficient distillation tool when speed and alcohol recovery are critical factors. With a single distillation, a pot still typically produces an aggregate alcohol strength of only 35–45% ABV from an 8–10% fermented beer or wash.

In addition, because of the pot still’s inherent inefficiency, the distillate from a single pass often contains a wide range of high- and low-boiling-point compounds. These congeners can impart harsh or undesirable characteristics to the spirit if not carefully managed.

For this reason, most distillers choose to redistill the spirit to improve purity, balance, and drinkability. While effective, this approach significantly increases resource consumption:

▪More heating energy

▪More cooling water

▪More cleaning time

▪More labor hours

Over time, these factors add up to higher operating costs.

What Is a Thumper?

A thumper—also known as a retort—is essentially a secondary kettle connected to the primary distilling kettle. It is heated indirectly by the vapor coming from the main still, making use of energy that would otherwise be lost.

The thumper gets its name from the distinctive “thumping” sound it makes as hot vapor bubbles through the liquid inside during operation.

Thumper or No Thumper?

Using a thumper allows the distiller to achieve a secondary distillation within a single run, eliminating the need to redistill the collected spirit.

Depending on the design, a thumper system may require more BTUs than running a single kettle alone, but it typically consumes less total energy than performing two completely separate distillation runs. Because the thumper contains liquid that facilitates an additional phase-change cycle, internal heat exchange can also reduce the overall cooling demand of the system.

While energy savings are important, the most significant advantage is often the reduction in labor hours, resulting in a more desirable finished spirit with less time and effort.

Charging the Thumper for Flavor and Complexity

One of the most powerful advantages of a thumper is its flexibility. The operator can charge the thumper with:

*Water

*Low wines or high wines

*Finished alcohol

*Additional flavoring components

Charging the thumper with specific liquids can promote the formation of carboxylic acids, which add depth and complexity to the finished spirit.

For gin production, botanicals can be added directly to the thumper. This approach prevents botanical oils from contaminating the primary kettle, which is typically larger and more time-consuming to clean.

Enter the Double Thumper (Double Retort)

Beyond a single thumper, a double thumper, also known as a double retort system, can further enhance distillation efficiency and spirit quality. This configuration provides additional ABV enrichment while stabilizing the alcohol strength of the collected distillate.

One of the most well-known applications of a double retort system is found in traditional Jamaican-style rum production. In this setup:

*The primary kettle is charged with rum wash (beer)

*One retort is charged with low wines

*The second retort is charged with high wines

This arrangement boosts ABV, increases ester formation, and enhances the development of desirable carboxylic acids—resulting in greater aromatic complexity and a more stable collection strength. Simply put, it adds more “rummyness” to the rum.

A More Flexible Double Thumper System

Modern double thumper systems take this concept even further by offering maximum operational flexibility.

The vapor manifold (lyne arm) can be equipped with three-way valves at each retort, allowing the operator to:

*Bypass one retort

*Bypass both retorts

*Run a simple stripping pass

*Redirect vapor to a separate distillation apparatus

This means the system is not limited to operating only as a double retort still.

Each retort is also commonly fitted with:

*Independent heat input

*A conventional column attachment point

This allows either retort to function as a standalone small pot still, ideal for pilot batches, specialty products, or R&D work.

Ultimate Versatility in a Single System

Additional custom features can be incorporated to expand capabilities even further. These may include:

*Multiple product condensers

*Vapor infusion hardware

*Rectifying columns

*Advanced vapor path control via valved manifolds

A well-designed system can seamlessly transition between:

*Traditional pot still operation

*Single or double thumper distillation

*A small column for bright, clean mouthfeel in flavored spirits

*A full rectifying column for neutral spirits

In some configurations, a dedicated product condenser is installed to reduce cleaning requirements on the rectifier side. Advanced valve manifolds can even allow the primary kettle and retorts to operate independently, enabling the production of multiple different spirits at the same time.

For breweries expanding into distillation, flexibility is everything. A thoughtfully designed pot still system—enhanced with single or double thumpers—offers the ability to produce a wide range of spirits without sacrificing efficiency or flavor integrity.

By combining traditional distillation principles with modern engineering, today’s hybrid brewery-distillery can achieve maximum creativity, efficiency, and return on investment. If you are interesting in any distillery system, please feel free to ask us.

Edited By Daisy

[email protected]