How to brew Ginger beer? Below is a step-by-step guide for both versions.

1. Ingredients for Ginger Beer

Basic Ingredients: Fresh Ginger Root (200-500g per gallon, depending on taste)

Sugar (White, brown, or honey—500g to 1kg per gallon)

Water (Filtered or spring water)

Yeast (Brewer’s yeast, champagne yeast, or wild fermentation)

Lemon Juice (Optional, for acidity balance)

Additional Ingredients for Flavor: Spices (Cinnamon, cloves, cardamom)

Fruit Juices (Pineapple, lime, or orange)

2. Brewing Process

Step 1: Prepare the Ginger Wort

Grate or finely chop the ginger. More surface area extracts more flavor.

Boil water in a brewing kettle. Use 1 gallon of water for a small batch.

Add the ginger and sugar to the boiling water. Stir well to dissolve the sugar.

Simmer for 20-30 minutes. This extracts the ginger’s spiciness.

Add any additional flavors. Lemon juice, cinnamon, or cloves can be added.

Cool the mixture to room temperature. Do not add yeast while hot, as heat kills yeast.

Step 2: Fermentation (Alcoholic vs. Non-Alcoholic)

A. Alcoholic Ginger Beer (1-6% ABV)

Transfer the cooled wort to a sanitized fermenter.

Add yeast (1g per gallon). Use champagne yeast for a dry finish, or ale yeast for a sweeter taste.

Seal with an airlock and ferment for 3-7 days at 18-24°C (65-75°F).

Check fermentation activity. Bubbling in the airlock indicates active fermentation.

Once fermentation is complete, siphon the ginger beer to bottles or kegs.

Carbonation Options: Bottle conditioning: Add priming sugar (5g per liter) before sealing bottles. Store for 3-7 days.

Forced carbonation: If kegging, use CO₂ to carbonate.

B. Non-Alcoholic Ginger Beer (Mild Fermentation for Fizz)

Use wild fermentation (ginger bug) or a small amount of yeast.

Ferment for only 24-48 hours to develop natural fizz.

Refrigerate immediately to stop fermentation.

Strain and bottle carefully. Use pressure-rated bottles to avoid explosions.

Which Equipment for Brewing Ginger Beer?

Ginger beer is a fermented beverage made from ginger, sugar, water, and yeast. It can be alcoholic or non-alcoholic, depending on the brewing process. Whether you're brewing at home or in a commercial setting, choosing the right equipment is essential for achieving high-quality results.

This guide explores the essential brewing equipment, ranging from small-scale home setups to large-scale commercial operations.

1. Essential Equipment for Homebrewing Ginger Beer

For homebrewers, the process is relatively simple and requires minimal equipment.

Here’s what you’ll need:

1.1 Fermentation Vessel

Glass Carboy or Plastic Fermenter: A 1-gallon or 5-gallon fermenter with an airlock is sufficient for small-batch brewing.

Food-Grade Bucket: Some brewers use a bucket with a tight-sealing lid and an airlock.

1.2 Brewing Kettle

Stainless Steel or Enamel Pot: A 5-10 gallon brewing kettle is ideal for boiling ingredients, including ginger, sugar, and spices.

1.3 Airlock and Bung

Fermentation Airlock: Ensures that carbon dioxide escapes while preventing contaminants from entering the fermenter.

Bung or Stopper: Used to seal the fermentation vessel and hold the airlock in place.

1.4 Straining and Filtering Equipment

Fine Mesh Strainer or Cheesecloth: Helps remove ginger solids and other particles after boiling.

Siphoning Tube: Transfers the liquid from the fermenter to bottles without disturbing sediment.

1.5 Bottling Equipment

Flip-Top Glass Bottles or PET Bottles: Ideal for carbonating and storing ginger beer.

Bottle Capper and Caps: If using standard glass bottles, a capper is needed.

1.6 Sanitizing Equipment

Sanitizer (e.g., Star San or Iodophor): Ensures all brewing tools are free of contaminants.

2. Equipment for Commercial Ginger Beer Production

Commercial brewing requires larger and more specialized equipment to ensure consistency, efficiency, and scalability.

2.1 Commercial Brewing Kettle

Steam-Jacketed Kettle: Allows precise temperature control, ensuring optimal extraction of ginger flavors.

Size: Typically ranges from 50 to 500 liters, depending on production volume.

2.2 Mash Tun (Optional for Some Recipes)

If using grains or complex sugar sources, a mash tun with a false bottom is necessary for starch conversion.

2.3 Commercial Fermentation Tanks

Conical Fermenters: Allow for easier yeast collection and sediment removal.

Size: Ranges from 50 to 1000 liters.

2.4 Filtration System

Plate and Frame Filter: Ensures a clean, sediment-free final product.

Carbon Filter: Removes unwanted flavors or impurities.

2.5 Carbonation System

Forced Carbonation Tanks (Bright Tanks): Used for controlled carbonation before packaging.

Carbonation Stones: Help dissolve CO₂ into the liquid efficiently.

2.6 Bottling and Kegging Equipment

Bottling Line: Automates the filling and sealing process for mass production.

Kegs (Cornelius or Sankey Kegs): Used for draft ginger beer dispensing.

2.7 Cooling and Temperature Control

Glycol Chiller: Keeps fermentation temperatures stable.

Cold Storage: Essential for maintaining product quality.

2.8 Cleaning and Sanitization System

CIP (Clean-in-Place) System: Automates the cleaning process of tanks and pipes.

3. Choosing the Right Equipment Based on Scale

| Scale | Equipment Needs |

| Homebrewing (1-10 gallons) | Glass carboy, brewing kettle, airlock, strainer, bottles, sanitizer. |

| Microbrewery (50-500 liters) | Steam-jacketed kettle, conical fermenter, carbonation system, filtration. |

| Commercial Brewery (500+ liters) | Large fermentation tanks, automated bottling, glycol chilling, CIP system. |

The choice of equipment depends on your production goals. Homebrewers can start with basic fermenters and kettles, while commercial producers need advanced systems for consistency and quality control. Proper sanitation, temperature control, and carbonation management are key factors in making great ginger beer.

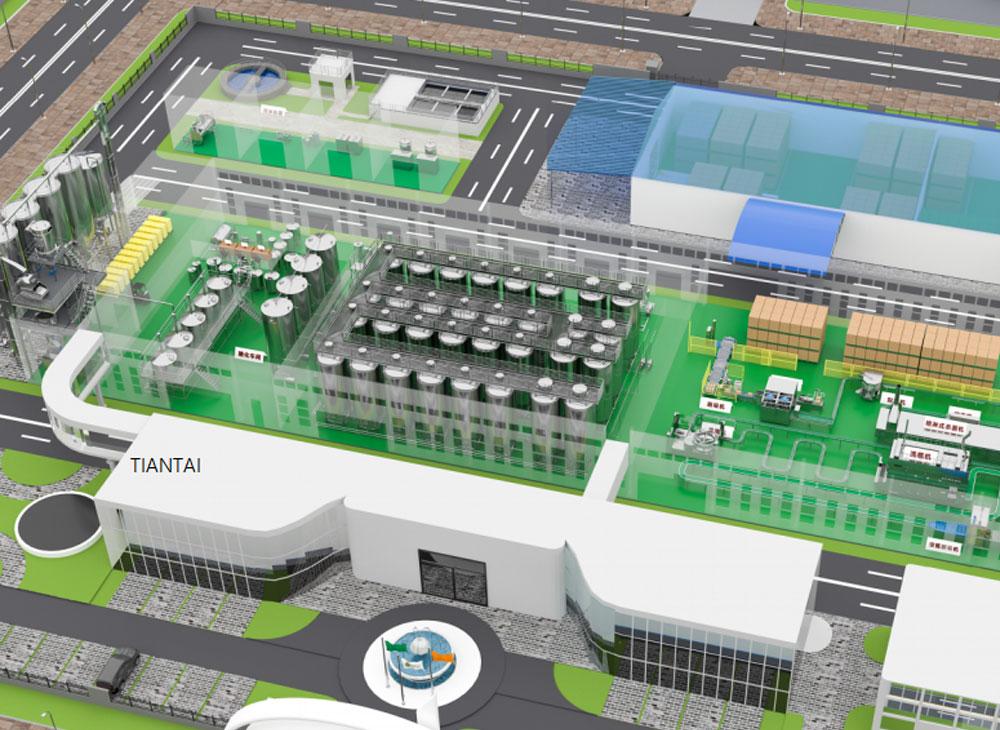

Why you choice TIANTAI brewing equipment?

Choosing TIANTAI Brewing Equipment for brewing operations—whether for craft beer or specialized beverages like ginger beer—offers several advantages.

1. High-Quality Manufacturing Standards: TIANTAI uses food grade 304 and 316 stainless steel, ensuring durability and resistance to corrosion. Precision welding and polishing help maintain hygiene and ease of cleaning.

2. Customization for Different Brewing Needs: We provide customized fermenters, brewhouses, and bright tanks tailored to different batch sizes.

Our equipment can be optimized for ginger beer brewing, including specialized fermenters with pressure control for carbonation.

3. Cost-Effective and Competitive Pricing: Compared to European or American manufacturers, TIANTAI offers a more affordable price without compromising on quality. Ideal for breweries looking to scale production without exceeding budget constraints.

4. Reliable After-Sales Service and Support: Technical support for installation and brewing process guidance. Spare parts availability ensures minimal downtime in case of repairs.

5. International Reputation and Proven Performance: Many craft breweries worldwide use TIANTAI equipment. Positive customer feedback highlights efficiency, durability, and cost-effectiveness.

6. Turnkey Solutions for Breweries: TIANTAI offers a full set of brewing solutions, including mash tuns, fermentation tanks, glycol chillers, and kegging systems. Suitable for startups, microbreweries, and large-scale production.

7. Energy Efficiency and Modern Technology: Steam and electric heating options allow energy-efficient brewing. Automated controls improve consistency and ease of operation.

Why Choose TIANTAI for Ginger Beer Production?

Custom Fermenters: Options for high-pressure fermenters for carbonated ginger beer.

Temperature Control: Essential for both alcoholic and non-alcoholic fermentation.

Efficient Cleaning (CIP Systems): Prevents contamination and off-flavors.

Scalability: Allows easy expansion from small to large production volumes.

Would you like help selecting specific TIANTAI equipment for your brewing setup? We warmly welcome your proposal!

Edited By Daisy Cai

[email protected]

.jpg)

.jpg)

.jpg)

Get In Touch