In modern craft beverage production, the brite tank—also known as the “bright beer tank” or “BBT”—is the final, essential vessel that prepares beer, cider, seltzer, kombucha, and other beverages for packaging and service. While brewhouse systems, fermenters, and cellaring equipment often get most of the attention, it is the brite tank that determines the final clarity, carbonation level, stability, and presentation of the finished product.

A well-designed brite tank ensures that the brewer or beverage maker can confidently deliver a clean, clear, properly carbonated product with consistent quality. Whether a small brewpub or a large-scale beverage facility, understanding the design, function, and engineering behind brite tanks is critical for streamlining production and improving product outcomes.

This comprehensive guide covers everything you need to know about brite tank design—including structure, materials, pressure ratings, cooling systems, carbonation features, cleaning systems, and how they can be adapted for beer conditioning, cider fermenting, and multipurpose beverage storage.

Part 1. What Is a Brite Tank?

A brite tank is a stainless-steel vessel used after fermentation and maturation to clarify, condition, carbonate, and store the final beverage before packaging. The tank’s name comes from the “bright,” visibly clear beer traditionally produced within it after yeast and solids drop out.

While originally used exclusively for beer, today’s brite tanks are highly versatile, popular for:

Beer conditioning and carbonation, Cider clarification and fermentation (when designed as pressure-rated), Seltzer and ready-to-drink beverages, Cold storage before packaging, Direct-to-tap service in brewpubs, Stabilization and blending.

Because of their cleanable design, polished interiors, and pressure capabilities, brite tanks have become a universal finishing vessel across multiple beverage industries.

Part 2. Brite Tank vs. Fermenter→ Key Differences

Although fermenters and brite tanks share some similarities, especially in modern pressurized systems, each vessel is optimized for different stages.

Fermenter (Unitank): Conical bottom for yeast harvesting and trub collection, Designed for vigorous fermentation, Often higher pressure rating for spunding and fermentation control, Equipped with cooling jackets along the sides and cone.

Brite Tank: Dish-bottom or 3–5% sloped flat bottom; No cone—maximizes usable volume and simplifies cleaning; Optimized for clarification, carbonation, and cold storage; Larger top access and racking arm for bright, clear liquid transfer; Reduced number of penetrations to minimize contamination risk.

Some customers will ask:” when to use a brite tank instead of a unitank?”

Tiantai answers: If you want maximum volume for packaging runs and you need higher carbonation precision, a dedicated vessel for cold crashing and serving. You need product separation to prevent cross-contamination of yeast, you will need brite beer tank.

While many breweries now use unitanks for both fermentation and conditioning, BBTs remain the gold standard for clarity, stability, and precise carbonation control.

Part 3. Materials and Construction: What Makes a High-Quality Brite Tank?

High-quality brite tanks are constructed from SUS304 stainless steel. Breweries working with acidic beverages (cider, kombucha) may choose SUS316 for greater corrosion resistance.

Inner Surface Polishing. A good brite tank must have: CIP-level inner finish of Ra 0.4 μm or better; Smooth welds, fully TIG welded; Full passivation to prevent corrosion and improve cleaning.

This sanitary finishing ensures no contamination traps and improves flavor stability.

Part 4. Tank Geometry & Structural Design

|

Top Design

|

▪Dished top with manway for easy access

▪Pressure rating between 1–3 bar (15–45 psi) ▪Pressure relief valve (PRV) for safety ▪Sparging stone port for carbonation ▪CIP spray ball for automated cleaning |

|

Bottom Design |

▪Dished bottom for strength

▪Or shallow-slope flat bottom (for serving tanks) ▪Centrally located drain for complete emptying ▪Offset racking arm for clear beverage withdrawal

|

|

Sidewall Reinforcement |

▪Fully welded stiffening rings

▪ASME-compliant reinforcement around fittings ▪Burst-proof pressure design |

Part 5. Cooling & Temperature Control System

Temperature control is essential for maintaining cold storage and ensuring carbonation efficiency.

Cooling Jackets→Most brite tanks include: Dual-zone or full-side jacket coverage, Glycol inlet/outlet with butterfly valves, Insulated jackets for maximum efficiency.

Insulation →Standard insulation is polyurethane foam, typically 80–100 mm thick.

Good insulation: Maintains stable internal temperature, Reduces glycol consumption, Prevents condensation

External Cladding→ The tank exterior typically features: Polished stainless steel, Diamond-plate or brushed finish, Protective bottom skirt.

Part 6. Carbonation System: Achieving Perfect CO₂ Levels

One of the most important functions of a brite tank is carbonation.

Carbonation Stone→A standard BBT includes:Microporous carbonation stone, usually 0.5–2 microns; Connected to a stone port on the tank wall; Used with precise CO₂ pressure regulation; Allows “force carbonation” to desired volumes.

Carbonation Process→ The brewer can: Chill the beverage to 0–2°C, Inject CO₂ through the stone, Allow the gas to dissolve uniformly, Measure levels using either head pressure or a dedicated carbonation tester

Proper carbonation design ensures: Faster carbonation + Finer bubble structure + Stable foam and mouthfeel.

Part 7. Tank Fittings and Accessories

A complete brite tank includes: Sanitary Connections, Tri-clamp fittings, CIP spray ball, Sample valve, Pressure gauge, Vacuum relief valve, Carbonation stone assembly, Racking arm, Dry-hop or sugar-addition port (optional).

Racking Arm→Critical for drawing off clear product, the racking arm: Rotates internally, Allows withdrawal above settled sediment, Preserves clarity.

Sight Glass (Optional)→Useful for brewpub serving tanks or high-end production monitoring.

Level Gauge (Optional)→Can be: Mechanical (sight tube), Electronic (pressure differential), Typical for larger tanks (>10 bbl / 12 hl).

Mobile and Horizontal Brite Tanks→Many breweries also choose: Portable serving tanks on wheels, Horizontal BBTs for lagering and space optimization.

Part 8. Pressure & Safety Systems

Because BBTs are pressurized vessels, they require: Pressure Rating with 1–3 bar, we also can customized the working pressure up to 4 bar or more for special beverages.

Safety Systems including PRV (pressure relief valve), Vacuum valve (for CIP and cooling cycles).

Explosion-proof manway (for high pressure), this ensures safe operation during carbonation and packaging.

Part 9. Cleaning and Sanitization Systems (CIP)

A brite tank must be easy to clean for safe beverage production.

CIP Spray Ball should be 360° coverage, fixed or rotating spray ball, designed to distribute flow evenly. It also can works with hot water, caustic, and sanitizer.

Drain & Slope→The tank must: Drain completely, Avoid “dead spots”, Have polished internal welds to prevent residue.

A poor CIP design leads to contamination risks—especially dangerous in cider and RTD production.

Part 10. Brite Tanks for Beer Conditioning

| Clarity and Brightness | Cold Crashing | Final Carbonation | パッケージング |

| When beer enters the brite tank:

Most yeast and hop particles drop out; Any remaining haze falls to the bottom; Racking arm pulls clear (“bright”) beer above sediment. |

Optimal temperature: 0–2°C;

Increases clarity; Improves carbonation absorption; Enhances stability.

|

Breweries use brite tanks to reach:

2.2–2.7 vols CO₂ (ales) 2.6–3.0 vols CO₂ (lagers and pilsners) 3.0–3.5 vols CO₂ (wheat beers) |

From BBT to:

Canning line ボトリングライン Kegs Direct-to-tap |

Part 11. Brite Tanks for Cider Fermenting & Storage

Cider has different requirements from beer.

Fermentation in Brite Tanks →Pressure-rated brite tanks allow: Slow, cold fermentation, Secondary fermentation, Carbonation under pressure, Blending and aging.

Because cider has higher acidity, SUS316 stainless steel may be preferred.

Clarification→Cold storage allows: Pectin settlement, Yeast drop-out; Clear, bright cider

Carbonation→ Most ciders require: 2.8–3.5 vols CO₂

A BBT provides precision and safety when carbonating.

Storage→ Low-temperature stability is crucial for cider shelf life, and brite tanks provide uniform, chilled conditions.

Part 12. Brite Tanks for Non-Beer Beverages

Seltzer & Hard Seltzer→Requires: High clarity, High carbonation (>3.0 vols), Flavor blending capability.

Cold Brew Coffee→Needs: Oxygen-free storage, Stable temperature, Easy transfer to packaging lines.

Kombucha →Requires: Higher acidity tolerance, Optional pressurization, Safe carbonation

RTD Beverages→Brite tanks support: Blending, Pasteurization prep, Stabilization, Nitrogen or CO₂ dosing.

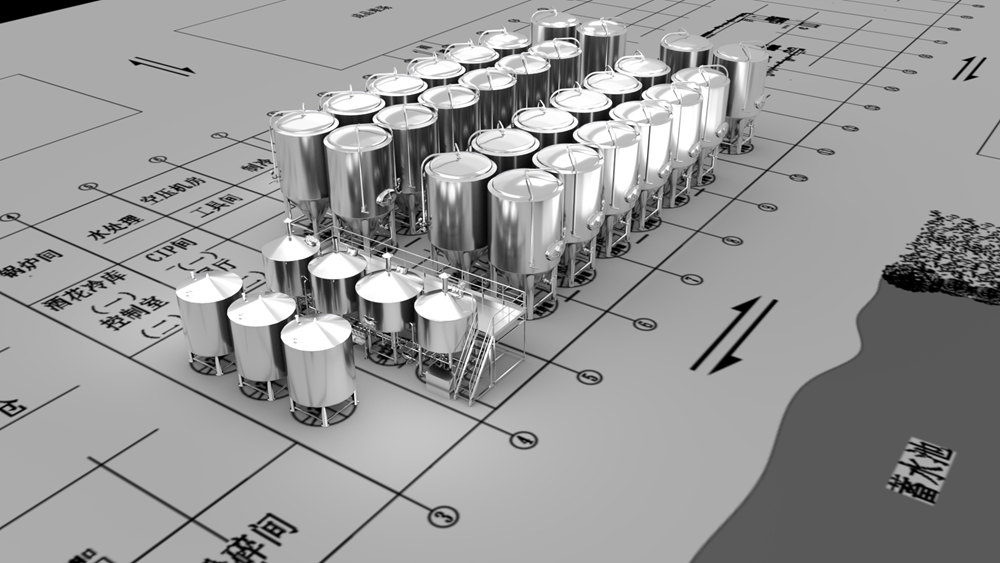

Part 13. Capacity Options & Customization

Brite tanks come in a wide range, including:

1–3 bbl brewpub tanks

5–30 bbl production tanks

60–200 bbl large-scale tanks

Fully custom engineered options

Common Customizations: Horizontal design for lagering

Vertical serving tanks with bagged liner

Stackable BBTs for small spaces

High-pressure design

Integrated carbonation system

Sight glass and level indicator

CO₂ recirculation loop

Portable service tanks on wheels

Part 14. Why Invest in a High-Quality Brite Tank?

A well-designed BBT improves: Product clarity, Flavor stability, Packaging consistency, Carbonation precision, Operational efficiency, Safety.

Because it is the final step before customers enjoy the product, poor brite tank design can result in: Over-carbonation, Under-carbonation, Haze issues, Yeasty flavor, Contamination, Packaging downtime.

Your brite tank is the last line of defense for beverage quality.

Part 15. Why Tiantai Brite Tanks?

Tiantai brite tanks are engineered for: True sanitary design with mirror-polished welding, Precise temperature control with efficient glycol jackets, High carbonation efficiency, Safe pressurization and long-term durability, With full customization options, Tiantai supports breweries, cider factories, and beverage plants of all sizes.

A brite tank is far more than a storage vessel—it is a precision-engineered tool responsible for the clarity, carbonation, stability, and final quality of your beverage. Whether conditioning beer, fermenting cider, storing seltzer or kombucha, or preparing RTD beverages, a well-designed brite tank ensures consistent results, efficient operation, and premium product presentation.

Understanding the complete design—from geometry, pressure rating, and insulation to carbonation systems, fittings, and cleaning capabilities—allows producers to select equipment that meets their needs today while scaling for tomorrow. Tiantai beer equipment company can provide you high quality and professional brite tank, and customize the diameter accordingly to the site ceiling height. If you are looking for brite tank, please feel free to ask us.

編集者:デイジー

[email protected]