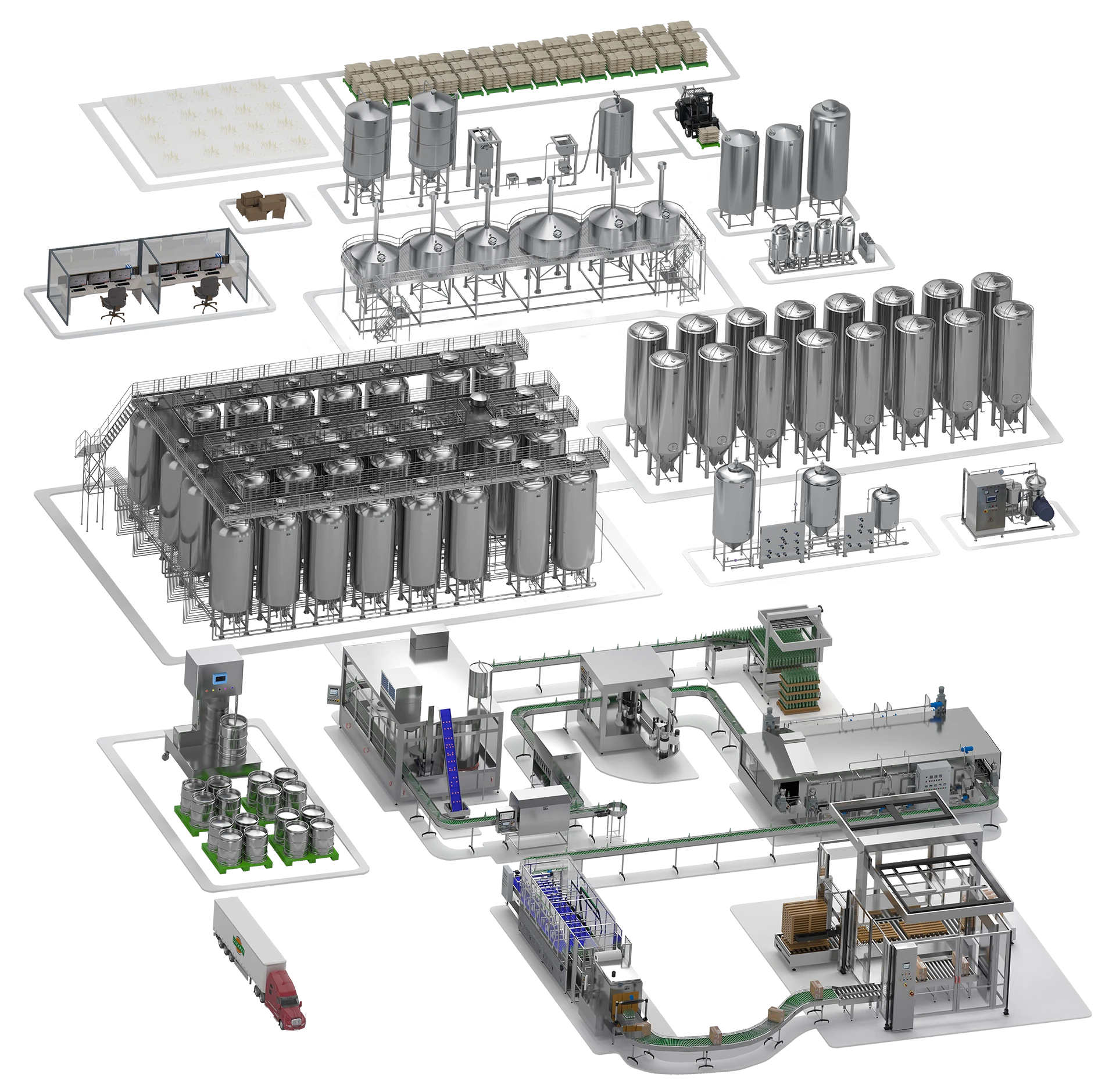

天泰ビール設備有限公司は、製粉機、醸造所、発酵槽、ブライトビールタンク、ビール瓶詰機、ビール缶詰機、ワイン、コンブチャ機器、蒸留器機器を含むビール醸造醸造設備システムを提供しています。

ビール醸造の世界では、黄金色の液体の一滴一滴が生まれるまでが精密な芸術的パフォーマンスである。大麦の発芽からマッシング、煮沸まで、すべての工程が最終製品の風味と品質に影響を与える。この一連の複雑な工程の中で、麦汁ろ過は一見単純だが非常に重要な工程であり、静かに技術革新が進んでいる。伝統的なフィルタータンクは、より効率的で精密な圧力ろ過装置へと徐々に移行しつつあり、品質と効率を向上させる現代の醸造所の秘密兵器となっている。

現在、大型の工業用醸造設備では、自動マッシュフィルタープレスがますます普及している。

従来のろ過の課題と限界

ビール醸造の歴史を振り返ると、麦汁ろ過は常にビールの透明度と純度を決定する重要なステップでした。伝統的なフィルタータンク方式は古典的なものですが、一貫性、効率性、資源利用という現代の醸造の厳しい要求に直面すると、次第にその限界が明らかになってきました。濾過速度が遅い、麦汁の損失率が高い、透明度を一貫してコントロールするのが難しい、特殊な穀物や複雑なレシピへの適応性に限界がある、などです。このような問題から、醸造業者はより高度な技術的解決策を求め続けている。

ろ過プレス技術:精密ろ過の現代的解釈

最新の麦汁フィルタープレスは、こうした課題に対する革新的な答えである。この装置では、横に並んだ一連のフィルタープレートを専用のろ布で挟み、複数のろ過ユニットを形成している。加圧下で麦汁がろ布を通過する一方、アフターバーナーは効果的に保持され、固液分離を正確に制御することができる。

従来の方法と比較して、ろ過プレス技術の核となる利点は、**制御可能な圧力システム**にあります。醸造者は麦汁の粘度やアフターバーナー層の厚さなどの要因に基づいて圧力パラメーターを正確に調整することができ、バッチごとに最適なろ過結果を確保することができます。この精密なコントロールは、濾過効率を向上させるだけでなく、製品品質の安定性を保証します。

技術革新:ろ過を超える包括的ソリューション

最新のフィルタープレスの技術革新は、基本的なろ過をはるかに超えています。大手機器メーカーは、いくつかのインテリジェント技術をシステム設計に組み込んでいます:

**インテリジェント・リンス・システム**は、ろ過後にろ布を自動的に洗浄するため、手作業を大幅に減らすと同時に、すべてのろ過が最適な衛生条件の下で行われるようにします。一部のハイエンドモデルでは、ろ布のセルフクリーニング技術も搭載しており、ろ布の寿命を大幅に延ばし、運転コストを削減します。

**省エネ設計**は、最新のフィルタープレスのもう一つの大きな目玉である。圧力曲線と回収システムを最適化することで、新世代の装置は30%以上のエネルギー消費を削減することができ、同時に水の消費量も削減し、世界のビール業界で高まる持続可能性のニーズに応えます。

**データ統合機能**は、フィルタープレスをインテリジェントな醸造エコシステムに真に統合します。濾過速度、濁度、圧力などの主要パラメーターをリアルタイムで監視し、中央制御システムとシームレスに統合することで、醸造メーカーは濾過プロセスを遠隔監視・調整することができ、真にインテリジェントな生産が実現します。

経済的メリット:目に見える投資利益率

経済的なメリットは、あらゆる経営判断に不可欠な要素です。最新のフィルタープレスは、この点においても同様に素晴らしいものです:

麦汁収量の増加はフィルタープレスの最も直接的な経済的利点である。より徹底した固液分離により、フィルタープレスは同量の原料から3~5%多くの麦汁を抽出することができ、大規模生産ではかなりのコスト削減につながる。

ろ過時間の短縮も大きなメリットをもたらします。従来の方法に比べ、フィルタープレスは濾過時間を30~50%短縮することができ、設備の稼働率を向上させるだけでなく、生産サイクル全体を加速させ、醸造所は市場の需要により柔軟に対応することができます。

ビールロスの削減も大きな利点です。クローズドループフィルタープレスシステムは、酸化のリスクを大幅に低減し、精密なコントロールは麦汁の残留を減らし、その結果、従来の方法と比較して全体的に2~4ポイントのビールロスの削減を実現します。

風味保護:ろ過技術の品質へのこだわり

効率や経済的な利点だけでなく、フィルタープレス技術によるビールの風味の保持も同様に注目に値する。密閉された濾過環境は麦汁と酸素の接触を効果的に減少させ、酸化のリスクを下げ、ホップと麦芽のデリケートなアロマを保護します。同時に、均一なろ過圧力がタンニンなどの好ましくない物質の過剰抽出を防ぎ、純粋なビールの味を保証します。

革新的な風味を追求するクラフトビール醸造所にとって、フィルタープレスはレシピの自由度を高めます。小麦の比率が高かろうが、オーツ麦やライ麦のような特殊な穀物を使おうが、フィルタープレスはそれを安定的に処理することができ、醸造家がより複雑で多様な風味コンセプトを実現するのに役立ちます。

アプリケーションの実践大規模ビール醸造所からクラフトビール醸造所まで

フィルタープレス技術は適用範囲が広く、1日に数千リットルを生産する大規模な醸造所から少量生産のクラフトビール醸造所まで、あらゆる醸造所に適したソリューションを提供します。大規模な醸造所ではフィルタープレスによってスケールメリットと安定した品質を実現し、クラフトビール醸造所ではその柔軟性と特殊な配合への適応性を活用してユニークな製品を生み出しています。

特筆すべきは、最新のフィルタープレスの設計が使いやすさを優先していることである。モジュラー設計により、さまざまな生産能力のニーズに対応することができ、直感的なユーザーインターフェースにより、経験の浅いオペレーターでもすぐに使いこなすことができます。

持続可能な醸造:フィルタープレス技術の環境貢献

環境への意識が高まる今日、フィルタープレス技術もまた、環境に優しい価値を発揮している。効率的な水のリサイクルシステムは水の消費量を大幅に削減し、最適化されたエネルギー消費設計は電力消費量を削減し、濾過後に得られる乾燥麦汁は含水率が低いため輸送重量を減らし、家畜飼料としての価値を高め、資源循環のクローズドループを形成する。

将来の展望インテリジェント・フィルトレーションと醸造イノベーション

IoT、ビッグデータ、AI技術の絶え間ない発展により、ろ過装置はより高度なインテリジェンスへと進化している。将来的には、原料の特性に基づいてろ過パラメーターを自動的に最適化する自己学習機能を備えたろ過システム、予期せぬダウンタイムを最小限に抑える予知保全機能、ろ過と糖化や発酵などのプロセスとの間に緊密な相乗効果を生み出し、ビール製造プロセス全体の最適化を推進する醸造データのより深い統合などが期待される。

結論

麦汁フィルタープレスは、もはや単なるろ過装置ではなく、精密工学、インテリジェント制御、醸造技術を統合した現代のビール醸造における包括的なソリューションです。伝統的なビール醸造の品質追求はそのままに、現代技術の効率と精度を取り入れ、ビールの長い伝統と革新的な未来をつなぐ重要な架け橋となっています。

澄み切った鮮やかなビールグラスの奥には、静かに作動するフィルタープレスがあり、純粋な風味を一滴一滴丁寧に濾過し、ビール本来の特徴を保っているのかもしれません。卓越性を追求する醸造業者にとって、高度な圧力ろ過技術を選択することは、効率を向上させるだけでなく、ビール文化を尊重し、保存することでもあります。

技術革新が醸造の芸術と出会うとき、濾過された麦汁の一滴一滴が完璧な風味を約束します-これは現代の圧力濾過技術がビールの世界に提供する最も貴重な贈り物です。自動マッシュフィルタープレスは、産業醸造分野で効率的なろ過を行うには本当に良い選択です。