Temperature control is one of the most important factors in fermentation, directly impacting yeast performance, flavor development, and product stability. To manage temperature effectively, breweries, wineries, and kombucha producers rely on cooling systems integrated into their fermentation tanks. Two of the most common designs are dimple jackets and coil jackets. Each has its own advantages, applications, and cost considerations. Here’s a clear breakdown to help you choose the right option for your production needs.

Understanding the Basics

Both dimple jackets and coil jackets circulate chilled glycol or water around the tank to maintain desired fermentation temperatures. However, the design and heat transfer efficiency differ.

1.What is a Dimple Jacket?

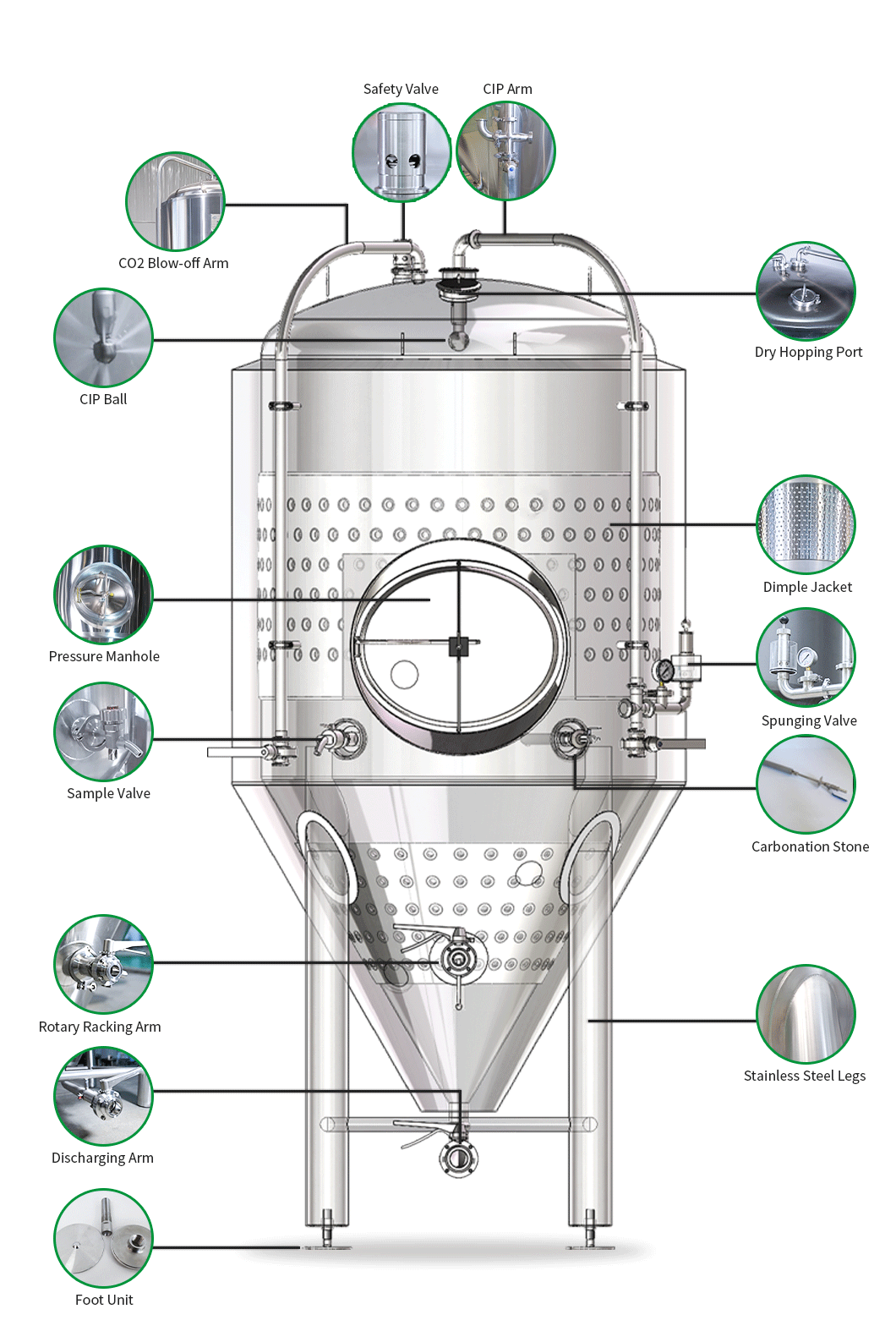

A dimple jacket is a thin layer of metal embossed with small concave “dimples,” welded onto the exterior of a tank. This creates channels for coolant to flow evenly across the surface.

メリット

Excellent heat transfer efficiency due to uniform coolant distribution

Durable and pressure-resistant, suitable for large tanks

Smooth interior tank wall, making cleaning easy

Aesthetic and compact, creating a clean professional look

Ideal for:

Large fermentation tanks, jacketed brite tanks, wine tanks, and high-impact cooling applications.

2.What is a Coil Jacket?

A coil jacket (sometimes called external cooling coils) uses welded stainless steel tubes wrapped or mounted around the tank. Coolant flows through these coils to absorb heat from fermentation.

メリット

More economical—lower cost compared to dimple jackets

Easy to repair or replace, as coils are external

Flexible installation, suitable for smaller tanks or retrofitting

Localized cooling—coils can be positioned based on tank height

Ideal for:

Small fermentation tanks, kombucha tanks, pilot systems, and budget-conscious projects.

3.Key Differences at a Glance

Feature Dimple Jacket Coil Jacket

Cost Higher Lower

Cooling efficiency Excellent, uniform Good, localized

Durability Very high Moderate to high

Space usage Compact Can extend outwards

Cleaning Easy (smooth walls) No impact on interior cleaning

Tank size suitability Medium to large tanks Small to medium tanks

4.Which One Should You Choose?

Your choice depends on budget, tank size, and fermentation style.

Choose a Dimple Jacket if:

You operate medium to large fermentation tanks (1,000–10,000+ L)

You need precise, uniform temperature control

Energy efficiency is a priority

You want a sleek, professional tank design

Your fermentation generates intense heat (beer, wine, kombucha, cider)

Dimple jackets deliver consistency and durability, making them a long-term investment for serious production facilities.

Choose a Coil Jacket if:

You’re working with smaller tanks (100–1,000 L)

You need a cost-effective cooling solution

You have limited glycol capacity

You want easy maintenance and replacement

You’re building a pilot system or starting a small brewery or kombucha operation

Coil jackets are practical, affordable, and flexible for early-stage or small-scale setups.

5.Hybrid Systems: The Best of Both Worlds

Some manufacturers combine lower-level dimple jackets with upper coil zones for improved cost control and heat management. Hybrid designs let you tailor the cooling system to your fermentation profile and budget.

Both dimple and coil jackets offer effective temperature control—but they serve different needs. Dimple jackets excel in performance and durability for commercial-scale operations, while coil jackets provide flexibility and cost savings for smaller systems. By understanding your production goals, tank size, and cooling capacity, you can choose the right jacket type to ensure stable, efficient, and high-quality fermentation.

The right temperature control system isn’t just equipment—it’s key to producing great beer, wine, kombucha, or spirits. Cheers to better fermentation!

Tiantai company can provide you various fermenter range from 50L to 50,000L, if you interest any beer equipment, feel free to contact us for a quote.

ありがとう。

ヘレン