In the brewhouse lautering process, the management of wort flow is critical for efficiency, clarity, and protecting the grain bed. A seemingly simple piece of equipment—the wort grant—plays a major role in controlling the transfer of wort from the lauter tun to the wort kettle without damaging the grain bed or disrupting lautering. Although not every brewery uses a grant, understanding its function helps brewers optimize their lautering system.

This guide explains:

♦What a wort grant is?

♦Why it is used?

♦How it protects the lauter tun?

♦Key design features

♦Advantages & disadvantages

♦Alternatives (direct pump connection, flow meter systems, differential pressure design, VFD pump control, etc.)

1. What Is a Wort Grant?

A wort grant (also called a “grant vessel” or “underback”) is a small, open or semi-open tank positioned between the lauter tun and the wort pump.

Instead of pumping wort directly from the lauter tun, wort flows first into the grant by gravity. Then the pump pulls wort from the grant and transfers it to the kettle. This acts as a buffer between the lauter tun and the pump.

Because the vessel is not pressurized, it prevents the pump from creating suction directly on the grain bed.

2. Why a Wort Grant Is Necessary?

2.1. Protects the Grain Bed from Compaction

If a pump pulls directly from the bottom of the lauter tun, it can create negative pressure (“vacuum”) on the grain bed.

This causes: Compaction, Channeling, Slow run-off, Stuck mash

A wort grant eliminates this risk because the pump pulls from the grant, NOT from the grain bed.

2. 2. Allows Precise Control of Wort Flow Rate

The brewer can monitor: Runoff volume, Pump flow rate. Wort clarity.

This prevents pulling wort too quickly and disturbing the grain bed.

2. 3. Improves Vorlauf (Recirculation) Clarity

During vorlauf, cloudy wort recirculates until clear.

A grant helps by: Separating solids, Allowing easy recirculation, Ensuring consistent clarity before sending wort to the kettle

2. 4. Prevents Oxygen Ingress (if designed correctly)

Modern grants often include: CO₂ blankets, Closed or semi-closed lids, Outlet positioned to minimize splashing.

This prevents oxidation during lautering, especially important for lager breweries.

2. 5. Provides a “Surge Tank” for Pump Control

If flow increases or decreases, the grant absorbs the fluctuation.

This maintains a steady lautering flow, especially in automated systems.

3. How a Wort Grant Works (Step-by-Step)?

Step 1: Lauter tun drains wort via gravity

Wort flows through: false bottom, collection manifold, bottom outlet, grant inlet.

Step 2: Grant receives wort

The liquid level rises in the grant.

Step 3: Pump draws wort from the grant

Pump speed is controlled manually or via VFD (variable frequency drive).

Step 4: Pump transfers wort to the kettle

Holding a buffer level avoids: grain bed suction, pressure spikes, sudden flow changes

Some grants even have float switches that automatically adjust pump speed.

4. Grant Types and Modern Designs

| Features: | 장점: | 단점: | |

| Type A

– Open Grant (Traditional) |

Stainless steel box or cylinder | Simple | Higher risk of oxygen pickup |

| Visible wort flow | Inexpensive | Not ideal for lager breweries or large systems | |

| Easy to clean | Visual monitoring | ||

| Type B

– Closed or Semi-Closed Grant (Most Common Today) |

Sealed lid | Protects against oxidation | Slightly more expensive |

| CO₂ inlet | Ideal for craft breweries | ||

| Level sensors | Allows automation | ||

| 사이트 글라스 | |||

| Drain + pump connections | |||

| Type C

– Automated Grant with Level Control (Advanced) |

Float switches or pressure sensors | Fully consistent lautering | |

| PLC control | Protects grain bed automatically | ||

| Auto-adjust pump speed | Best for medium/large systems | ||

| Alarms for too high or low levels | |||

| This is often integrated in Tiantai’s advanced brewhouses. |

5. Alternative Lautering Designs (When a Grant Is Not Used)

Some breweries choose not to use a grant. Instead, they rely on controlled systems that prevent grain bed suction.

Here are the major alternatives:

Alternative A: Direct Pump Connection with VFD Control

Pump is connected directly to the lauter tun outlet.

To prevent suction, the pump uses: Low-speed VFD, Manual throttling, Brewer monitoring

Pros: Cheaper, and Simple.

Cons: Requires experienced operator; Risk of compaction if pump speed is wrong.

Usually acceptable for 3–10 bbl systems.

Alternative B: Differential Pressure Monitoring System

Modern breweries may skip the grant but install DP sensors.

DP sensors measure: Pressure above grain bed, Pressure below grain bed, The difference (ΔP)

When ΔP increases (sign of compaction), the controller slows the pump.

Pros: No grant needed, Automated safety, Very stable lautering.

Cons: Higher equipment cost, Requires PLC system.

Common in German brewhouses.

Alternative C: Manifold + Flow Meter System

A flow meter controls outgoing wort volume.

The brewer sets: Desired runoff rate, Target volume, PLC adjusts pump speed automatically.

Pros: Predictable lautering curves; Fast run-off.

Cons: Not as protective as a grant; Slight risk of bed disruption.

Alternative D: Gravity Lauter System (No Pump)

Used only in small brewpubs.

Lauter tun is elevated above the kettle and wort runs down via gravity.

Pros: Zero risk of suction; Very gentle lautering.

Cons: Height requirement; Slow runoff; Not suitable for modern compact breweries.

6. Should Every Modern Brewhouse Use a Wort Grant?

| Small Systems (≤10 bbl) | Medium Systems (10–30 bbl) | Large Systems (30–200 bbl) |

| Not mandatory. | Highly recommended. | Essential. |

| A properly controlled pump is enough. | Protects grain bed and improves consistency. | Flow fluctuations are too large without a grant. |

High-end lager or German-style brewhouses Always use a wort grant for:

Low oxygen brewing (LODO)

Gentle wort handling

Precise control

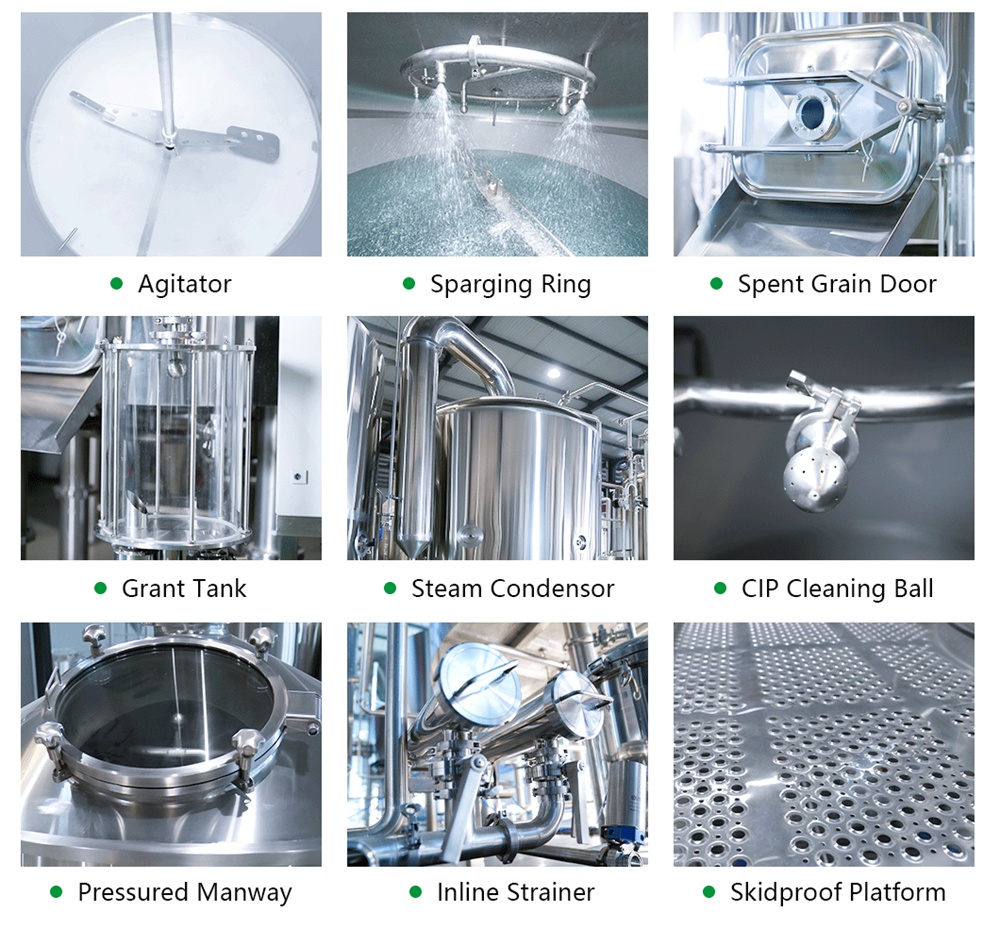

7. Key Design Features of a Good Wort Grant

A well-designed wort grant should include: Stainless steel 304/316, Sanitary, durable. Smooth internal polish (Ra < 0.6 µm), Easy to clean, no contamination traps. Sight glass, To observe wort clarity and level. CO₂ inlet for oxygen-free lautering (optional for craft, essential for lager breweries); Level sensors, High-level alarm, Low-level alarm, Automatic pump control; Separate drains for wort & CIP, Ensures hygiene. Tri-clamp connections, Easy maintenance.

8. What Happens If the Brewery Does NOT Use a Grant?

Possible issues: Grain bed compaction, Stuck mash, Reduced lautering efficiency, Turbid wort, Oxidation pickup, Inconsistent runoff, Higher beer color (from oxygen), Stress on the lauter tun false bottom.

A grant is inexpensive compared to the problems it prevents.

9. Tiantai’s Grant Design Options

Generally, Tiantai offers you : Open manual grant (small systems), Closed semi-automatic grant (10–20 bbl), Fully automated oxygen-free grant with PLC control (20–200 bbl systems), Optional low oxygen brewing configuration.

A wort grant is one of the simplest yet most important components of the wort lautering system. It protects the grain bed, stabilizes flow, improves clarity, and prevents oxygen exposure. Even though some modern breweries use alternative designs—like differential pressure sensors or advanced pump controls—the wort grant remains a highly effective and economical tool, especially in medium and large brewhouses.

편집자: 데이지

[email protected]