Hybrid distillery is a multi function distillery to do all kinds of spririts like Rum, vodka and Gin etc.

1) Introduciton of the Hybrid distillery

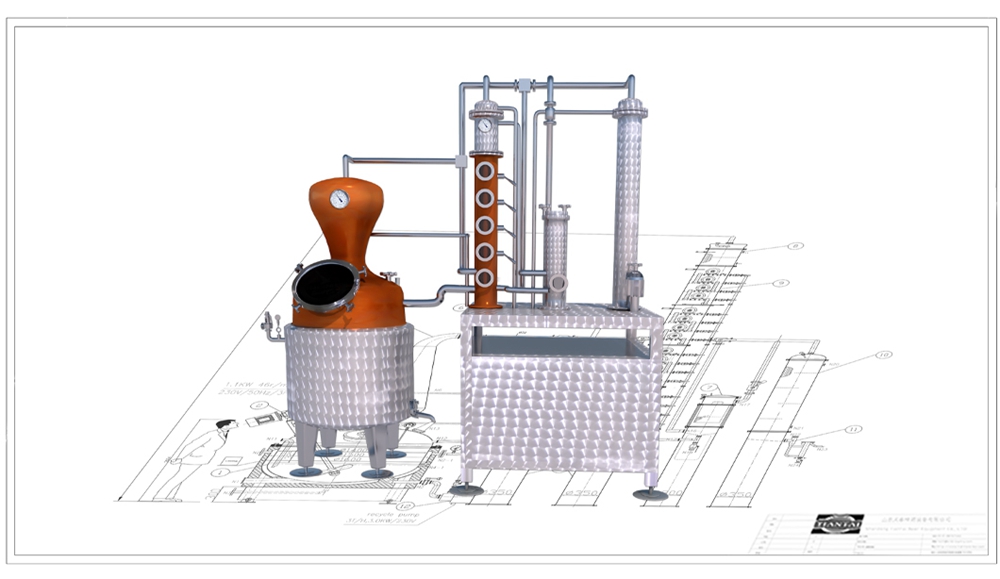

1. Hybrid Distillation Technology

The hybrid distillery system utilizes both pot still and column still technologies. The pot stills provide a traditional method of distillation, ideal for producing rich, flavorful spirits like Rum and Gin, where a more hands-on, artisanal process is desired. The column stills, on the other hand, offer continuous distillation, which is more suited for high-purity spirits like Vodka. This dual system enables distillers to have the flexibility to produce a wide variety of spirits using the most appropriate method for each type of spirit.

2. 100L-5000L 용량

The 100L-5000L capacity refers to the total volume of liquid that can be processed during each distillation cycle. This large capacity ensures high throughput, allowing the distillery to produce significant volumes of spirits, while maintaining quality control. This size is ideal for medium-scale production, serving both small craft distilleries and larger producers who need to meet market demand efficiently.

3. Copper Pot Still for Rum and Gin

One of the standout features of this hybrid system is the copper pot still, which is a key element in the production of Rum and Gin. Copper is widely regarded as one of the best materials for distilling, as it reacts with sulfur compounds in the wash, removing undesirable flavors and impurities, resulting in a smoother and cleaner distillate. The copper pot still allows distillers to carefully monitor the distillation process, ensuring that the final product retains its rich flavors and aromas.

4. Stainless Steel Construction for Durability and Efficiency

The main body inside is copper and outside is constructed from high-quality stainless steel. Stainless steel is chosen for its durability, corrosion resistance, and ease of cleaning. These properties are essential for maintaining hygiene in a distillery, as well as ensuring the system’s longevity. The high-grade material also improves the efficiency of heat transfer during the distillation process, ensuring energy is used efficiently, reducing operational costs.

5. Precise Temperature and Pressure Control

The distillation process requires precise control over temperature and pressure to ensure the desired separation of components from the wash. The 4000L hybrid distillery is equipped with advanced temperature and pressure regulation systems, which allow operators to control the process with great accuracy. This level of control ensures consistent production, with minimal variation in quality between batches.

6. Versatility in Production

This hybrid distillery is designed to be highly versatile, capable of producing a wide variety of spirits. For example: Vodka, Rum, Whisky, Gin, Rum etc.

7. Efficient Energy Use

The distillery system is designed to be energy-efficient, utilizing heat exchangers and other technologies to minimize energy consumption. This is crucial for maintaining low operating costs, as distillation can be an energy-intensive process. The heat exchange systems help recover and recycle heat from the distillation process, reducing the need for additional energy input.

8. Easy-to-Use Control Panel

The distillery is equipped with a user-friendly control panel that allows operators to easily monitor and adjust key parameters such as temperature, pressure, flow rates, and more. The intuitive interface simplifies the operation of the system, reducing the potential for errors and improving overall efficiency. Additionally, advanced sensors provide real-time data, allowing for prompt adjustments when necessary to ensure the highest quality distillation.

9. Cleaning and Maintenance

Routine cleaning and maintenance are essential in any distillery to ensure product quality and equipment longevity. The 4000L hybrid distillery system has been designed with ease of cleaning in mind. The stainless steel components are resistant to contamination and can be easily sanitized, while the layout allows for straightforward maintenance access, minimizing downtime.

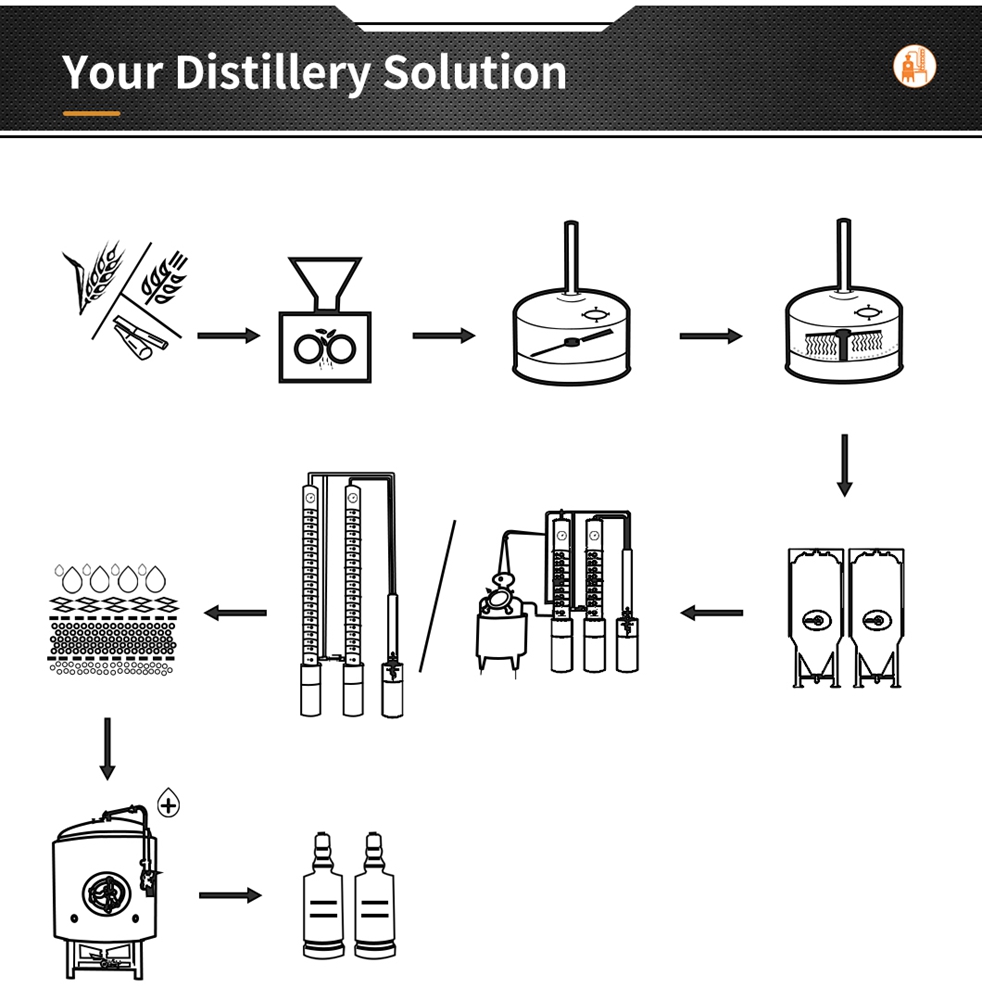

2) Applications in Spirit Production

This hybrid distillery system is perfect for producing a variety of distilled spirits, each with its own unique requirements and flavor profiles. Some of the most common applications include:

Vodka Production

Vodka is a neutral spirit, typically distilled to a high proof and then diluted to the desired alcohol content. This system can be used for continuous distillation, producing the purest form of Vodka. The distillery’s temperature control ensures that the ethanol is distilled without impurities, achieving the smooth, clean flavor profile that Vodka is known for.

Rum Production

Rum production involves the distillation of fermented sugarcane juice or molasses. The copper pot still in this system is perfect for this application, as it helps impart the characteristic richness and complexity to the rum. The distillery can be adjusted to create different styles of rum, from light and clean to dark and complex.

Gin Production

Gin is a versatile spirit that is typically made by infusing a neutral base spirit with a blend of botanicals. The pot stills in the 4000L hybrid distillery provide a perfect method for distilling and infusing these botanicals, allowing for the creation of a wide range of Gin styles, from classic London Dry to contemporary variations with exotic botanicals.

Whiskey Production

Though not initially intended for whiskey, the hybrid system’s versatility makes it suitable for whiskey production as well. With adjustments to the distillation process, this system can produce single malt, bourbon, or blended whiskey, depending on the distillation and maturation methods employed.

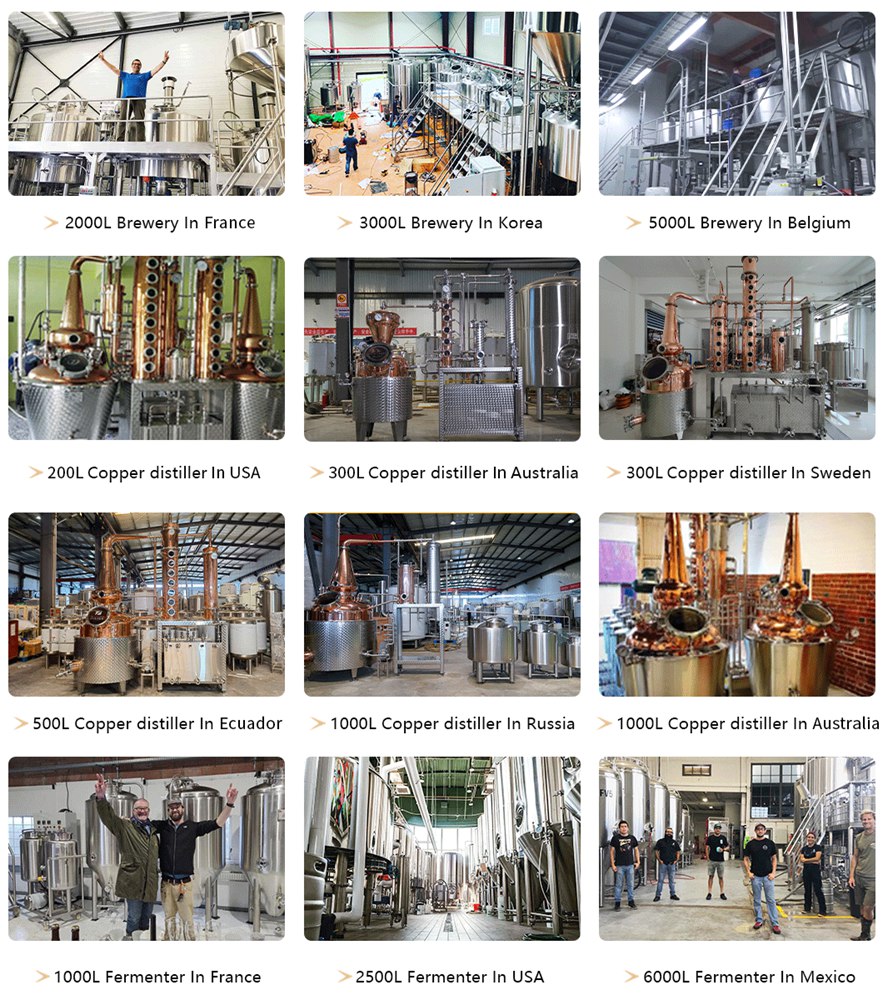

If you are interested in any beer brewery equipment or distillery, please feel free to contact us:

아이비 량(영업 이사)

이메일: [email protected]