What’s the Ingredients to brew cider?

1.Apples or Apple Juice

Fresh apples (sweet and tart varieties for balance) or 100% preservative-free apple juice.

Common cider apples include Kingston Black, Dabinett, and Yarlington Mill.

2.Yeast:Champagne yeast, cider yeast, or wild yeast.

Specific cider yeast strains can enhance fruity esters and maintain clarity.

3.Sugar (Optional):White sugar, brown sugar, honey, or maple syrup for increasing alcohol content.

4.Yeast Nutrients:Helps yeast perform efficiently and avoids fermentation issues.

5.Sulfites (Optional):Campden tablets to kill wild bacteria or natural yeasts before controlled fermentation.

6.Acid Blend and Tannins (Optional):Adjusts flavor balance by enhancing acidity or astringency.

7.Pectic Enzyme (Optional):Helps break down pectin for improved clarity.

.jpg)

What’s the Brewing Process?

Step 1: Preparing the Juice

If using fresh apples, wash, crush, and press them to extract juice.

If using store-bought juice, ensure it's free of preservatives like potassium sorbate.

Test sugar levels using a hydrometer; adjust with sugar if needed.

Add pectic enzyme (if used) and let sit for 12 hours to break down pectin.

Step 2: Sanitization

Sanitize all equipment that will come in contact with the cider.

If desired, add Campden tablets to kill wild yeast and bacteria, waiting 24 hours before pitching yeast.

Step 3: Fermentation

Pitch yeast into the juice.

Add yeast nutrient to ensure proper fermentation.

Seal with an airlock and place in a cool, dark location (60–75°F or 15–24°C).

Fermentation typically lasts 1–3 weeks, depending on yeast strain and temperature.

Use a hydrometer to monitor fermentation progress.

Step 4: Secondary Fermentation (Optional)

After primary fermentation, siphon cider into a clean carboy, leaving sediment behind.

Let it age for several weeks to months for improved clarity and taste.

Step 5: Bottling and Carbonation

If still cider is preferred, bottle directly.

For carbonated cider, add priming sugar before bottling.

Seal bottles and let them condition for 2–4 weeks.

Kegging is an alternative option for force-carbonation.

Step 6: Enjoying Your Cider

Chill cider before serving.

Experiment with aging for enhanced flavor complexity.

Brewing cider is a rewarding process that allows for creativity and experimentation. With the right equipment and ingredients, you can produce high-quality cider tailored to your taste. Whether crafting a crisp, dry cider or a sweet, sparkling variation, mastering these steps will help ensure success in every batch.

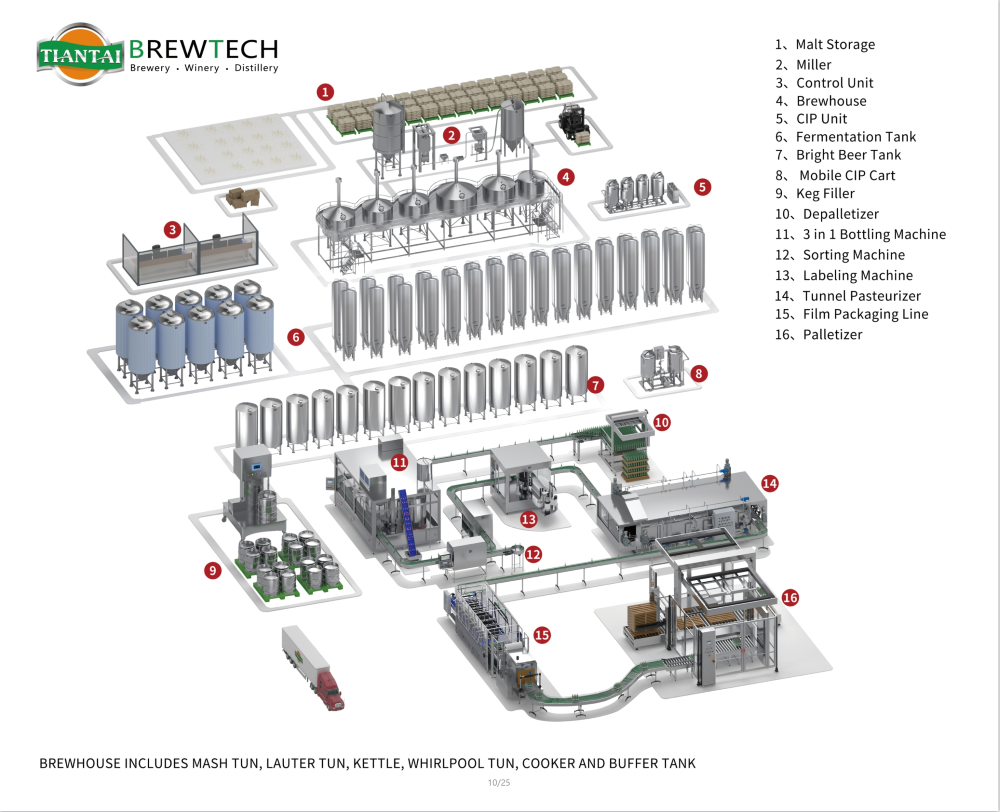

For factory-scale cider production, you will need industrial-grade brewing equipment to handle large volumes efficiently while maintaining quality. Here’s a list of essential equipment:

1.Apple Processing Equipment

Industrial Apple Crusher and Press – For high-capacity juice extraction.

Sorting and Washing Machines – To clean and remove debris from apples.

2.Fermentation Equipment

Large-Scale Fermenters – Stainless steel tanks with temperature control for consistent fermentation.

Glycol Cooling System – Regulates fermentation temperature.

Yeast Propagation Tanks – Helps cultivate yeast for large-scale fermentation.

Oxygenation System – Ensures proper yeast health and fermentation efficiency.

3.Filtration & Clarification

Plate or Membrane Filters – Removes sediment and clarifies the cider.

Centrifuge (Optional) – Speeds up clarification and removes impurities.

4.Packaging Equipment: Automated Bottling & Canning Lines – High-speed machines for efficient filling and sealing.

5.Kegging System – Industrial keg fillers for draft cider.

6.Pasteurization & Stabilization: Flash or Tunnel Pasteurizers – Extends shelf life and ensures microbial stability.

7.Carbonation System – If producing sparkling cider.

8.Quality Control & Testing

Laboratory Equipment – pH meters, refractometers, and microbiological testing for quality assurance.

9.Cleaning & Sanitization: CIP (Clean-in-Place) System – Ensures hygiene and prevents contamination.

.jpg)

Using TIANTAI cider brewing equipment offers several advantages, especially for large-scale cider production. Here’s why TIANTAI stands out:

1. High-Quality Stainless Steel Equipment: TIANTAI provides food grade 304/316 stainless steel fermentation tanks and processing equipment, ensuring durability, corrosion resistance, and hygiene compliance.

2. Customizable Solutions: TIANTAI design tailor-made brewing systems based on production capacity, space availability, and specific cider styles.

3. Advanced Temperature Control: TIANTAI fermenters come with glycol cooling jackets, ensuring precise fermentation control, which is crucial for cider quality.

4. Efficient Juice Extraction & Clarification: TIANTAI offers industrial apple crushers and presses, ensuring maximum juice yield with minimal oxidation.

5. Automated Processing for Efficiency: TIANTAI integrate CIP (Clean-in-Place) systems, automated bottling/canning/kegging lines, and filtration units for seamless operations.

6. Cost-Effective & Reliable: Compared to European or American brands, TIANTAI offers affordable yet high-performance equipment, making it ideal for both startups and expanding cider factories.

7. Global Support & Installation: TIANTAI provide on-site installation, technical guidance, and after-sales service worldwide.

.jpg)

Would you like help in selecting specific TIANTAI equipment for your cider production needs? We warmly welcome your proposal! Let’s provide you a specific brewing solution to build your cider brewery project.

Edited By Daisy Cai

[email protected]

.jpg)

.jpg)

.jpg)

Get In Touch