The whole brewery system contains grain malts milling machine , brewhouse, beer conical fermenter, bright beer tank, brewery control unit, Glycol cooling Unit and CIP Cleaning System, as well as beer kegs, keg filling & washing machine, beer bottles filling and capping machine, canning machine etc.

1. Pilot Beer Brewing Equipment 100L brewing kit This is a portable brewing system, with two carts. One is brewhouse cart, anther is beer fermentation carts. All the pipes, fittings, controls are connected very well at factory, you only need to provide electric power to start brewing beer. This small pilot beer brewing system are very popular for micro brewery, large industry brewery or home brewers for hobby.

| Item: | TIANTAI 100L Pilot Brewing System |

| Model: | TT-100L PBS |

| Capacity: | 100 liters beer per batch |

| Brewhouse Cart: |

100L Mash/Lauter Tun, 100L Kettle/Whirlpool Tun, complete pipes, valves, fitting, Heat Exchanger, Pump, Brewhouse Control Cabinet |

| More Option: | 100L Hot water Tank |

| Heating Method: | Electric heated (Steam or direct fire for option) |

| Fermenter Cart: |

100L Beer conical fermenter *2 sets, Glycol Chiller, Glycol water pipes, fittings and valves, Fermenter control cabinet. |

| Votalge: | 3phase 380V 50Hz (customized accordingly) |

The following image is 100L Brewhouse Cart

The following image is 100L beer fermenter cart

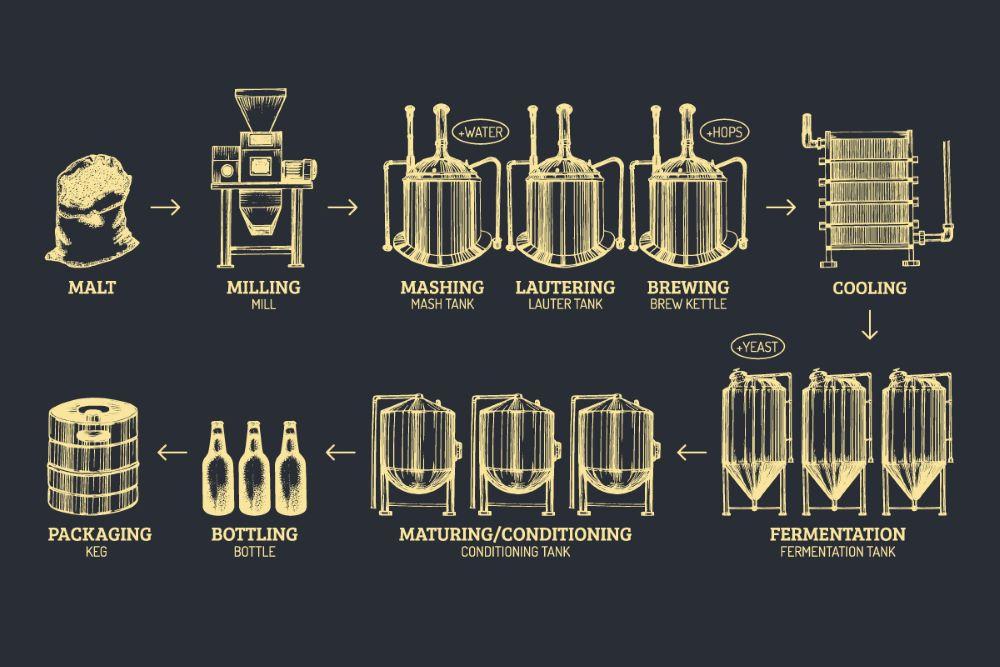

2.Beer Brewing Process:

The mashing process and the wort filtration process are completed by Mash/ lauter Tun; The boiling and whirlpool processes are completed in Kettle/whirlpool Tun.All the temperature is automatic controlled, after you setup the required temperature through the control cabinet, the heating or cooling process will be controlled automatically to reach the setup temperature.

If you want to design more automatic control, welcome your proposal ,we can customize it accordingly.

3.The Feature of TIANTAI Beer Brewing System:

> Two/Three/Four vessels with hot water,first batch takes about 8 hours, and two batches of 14 hours are allowed;> All certificated 304 stainless steel, easy to clean; Copper cladding for special environments such as brewpubs, restaurant, taproom;

> Steam heated, high thermal efficiency, gentle for wort; Electric or direct fire heating available;

> The wort cooled by tap water and -5 ºC ice water to cool in two stages, Single stage available;

> Mashing heating and fermentation cooling automatically controlled, and manual control switched at any time;

> Manual valve control, humanized operation, low equipment investment cost, high cost performance; PLC automatic control for upgrade;

.jpg)

4.Advantages of TIANTAI Brewery Equipment :

> With ISO TUV SGS, the product meets the GB/CE/PED/ASME standard> Local service in EUROPE, AUSTRALIA ETC

> 5 Years Warranty for tanks

> 0 trade risk verified by more than 1100 breweries

> 20 Years Manufacture and Management Experience

> Installed More than 1100 breweries in 76 Countries

.jpg)

TIANTAI beer equipment company can provide you different brewing system for option. 200L Pilot Brewing Equipment, 300L Brewing Cart, 400L Brewing Cart, 500L Brewpub Brewing System, 600L Restaurant Brewery System, 7BBL/800L Brewery System, 1000L Micor brewery Equipment......based on high quality and reasonable price TIANTAI has more and more customers all over the world, you can check Brewery Cases to learn more. If you are interesting any beer brewing equipment, please let me know.

Edited By Daisy Cai

Email Box: [email protected]

.jpg)

.jpg)

Get In Touch