The brewery could be with steam heating, or direct fire heating, two/three or four vessels brewhouse.

The system contains milling, brewhouse, fermenter, bright beer tank, control unit, Glycol cooling Unit and CIP Cleaning System, as well as kegging and Bottling system.

The mashing process and the wort filtration process are completed by Mash tun/ lauter tank; The boiling and whirlpool processes are completed by one tank.

This system usually brews two or three batches a day. According to different fermentation cycles of brewed beer, 6pcs double batches fermenters or 12pcs single batch fermentors can usually be configured.

The system also needs to be equipped with a complete automatic or manual control system, malt milling system, CIP system, cooling system, steam heating system, air system, etc.

.jpg)

2.Our Advantage

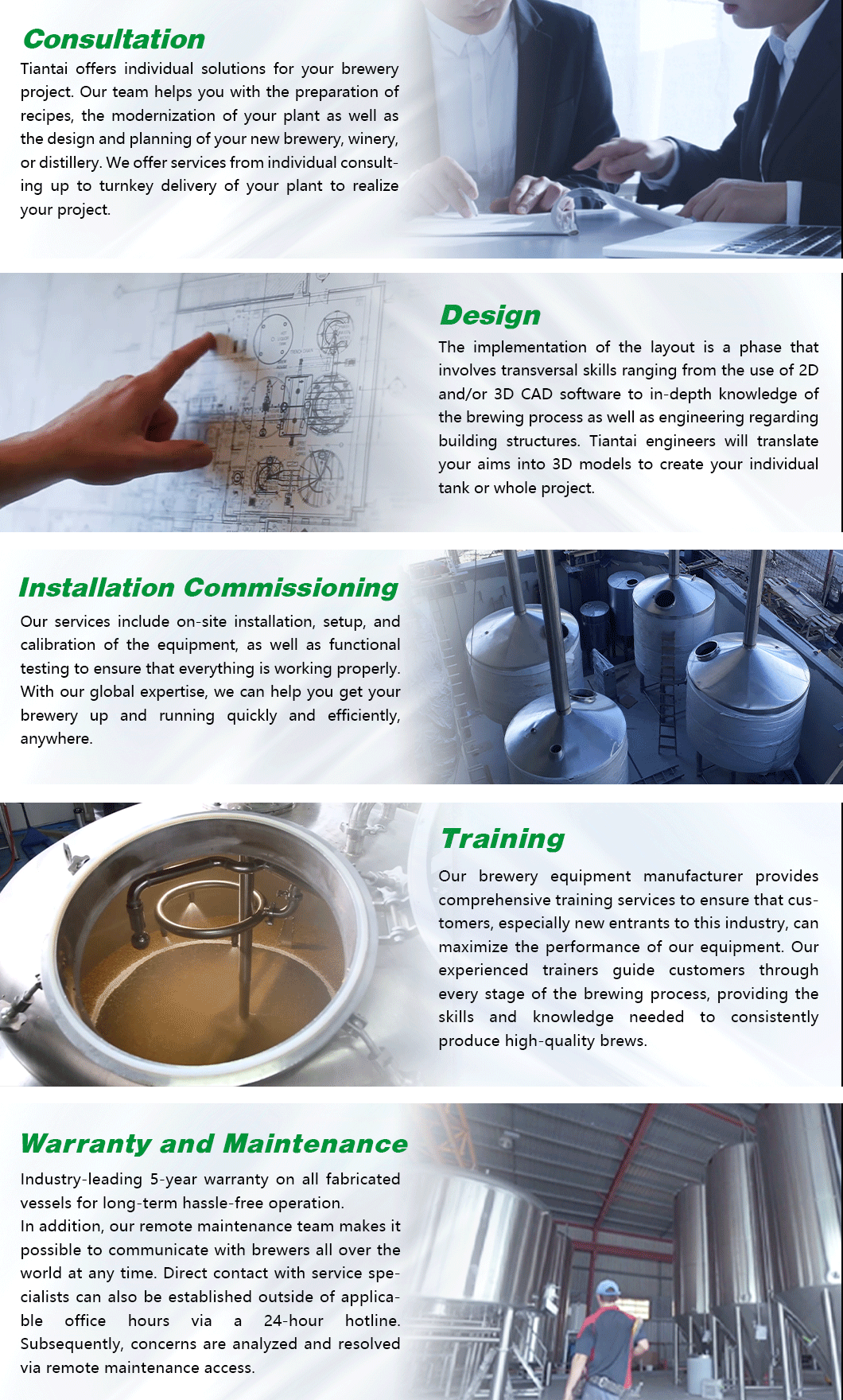

> With ISO TUV SGS, the product meets the GB/CE/PED/ASME standard

> Local service in EUROPE, AUSTRALIA ETC

> 5 Years Warranty for tanks

> 0 trade risk verified by more than 1100 breweries

> 20 Years Manufacture and Management Experience

> Installed More than 1100 breweries in 76 Countries

3.Features

> Two/Three/Four vessels with hot water,first batch takes about 8 hours, and two batches of 14 hours are allowed;

> All certificated 304 stainless steel, easy to clean; Copper cladding for special environments such as bars;

> Steam heated, high thermal efficiency, gentle for wort; Electric or direct fire heating available;

> The wort cooled by tap water and -5 ºC ice water to cool in two stages, Single stage available;

> Mashing heating and fermentation cooling automatically controlled, and manual control switched at any time;

> Manual valve control, humanized operation, low equipment investment cost, high cost performance; PLC automatic control for upgrade;

4.Specification

| Craft Microbrewery | Components | Main specification |

|

Brewhouse unit |

Mash Tun |

25% head space, Steam heating on cone and bottom With insulation Agitator&motor CIP, sight glass Mashing outlet |

|

Lauter Tun |

25% head space, False bottom Rake&motor Spent grain outlet Equally distributed Circular mouth wort outlet with extended collection ring at bottom Back pressure flushing device under false bottom with nozzels |

|

| Kettle/Whirlpool tun |

40% head space Steam heating with insulation Steam condenser Wort outlet and trub outlet Tangential inlet. |

|

|

Hot Liquor Tank |

70HL 15% head space Steam heating with insulation CIP Level gauge Hot water recycling port |

|

| Wort pump | 10T/hr, Sanitary | |

| Hot liquor pump | 10T/hr, Sanitary | |

| Plate heat exchanger |

35m2 Two stages Connected with wort aeration device Disassemble |

|

| Work platform |

Disassemble Adjustable |

|

|

OPTIONAL |

Wort grant Hopback Hopper Pneumatic valve Wort flow meter Sink Sterile air compressor |

|

|

Fermentation unit |

Fermentation tank |

3500L/7000L/30BBL/60BBL 25% head space Jacketed and insulated Conical bottom Pressure valve, relief valve CO2 relief valve Coolant inlet and outlet Sample valve Side manway Top, Dry Hopping Port CIP connections Wort inlet and yeast outlet Racking arm Temperature and pressure gauges |

|

Maturation/Storage (OPTIONL) |

Bright beer tank |

3500L/7000L/30BBL/60BBL 20% head space, Jacketed and insulated Dished head&bottom Pressure valve, relief valve Site Glass level Carbonation stone assembly Sample valve Side manway Fill/drainage port CIP connections Temperature and pressure gauges Jacketed and single wall tanks |

|

Glycol cooling system |

Glycol cooling tank |

35HL Thermowell Top manway CIP arm and spray ball 360 degree of coverage Thermowell |

|

Cold liquor tank (OPTIONAL) |

70HL Top manway CIP arm and spray ball 360 degree of coverage Visual level sight glass Cooling jackets |

|

|

Chiller |

2x15P Second generation Freon R407C, R410A, R404A |

|

| Glycol water pump and piping | PPR, UPVC, Stainless Steel Glycol Pipeline for optional | |

|

Controlling unit |

Brewhouse control panel |

Temperature monitoring& controlling Pump on/off control VFD control |

| Cellar control panel |

Temperature monitoring& controlling More controllers reversing for expansion available |

|

|

Cleaning unit |

Alkali tank | 300L |

| Sterile tank | 300L | |

| Pump and piping |

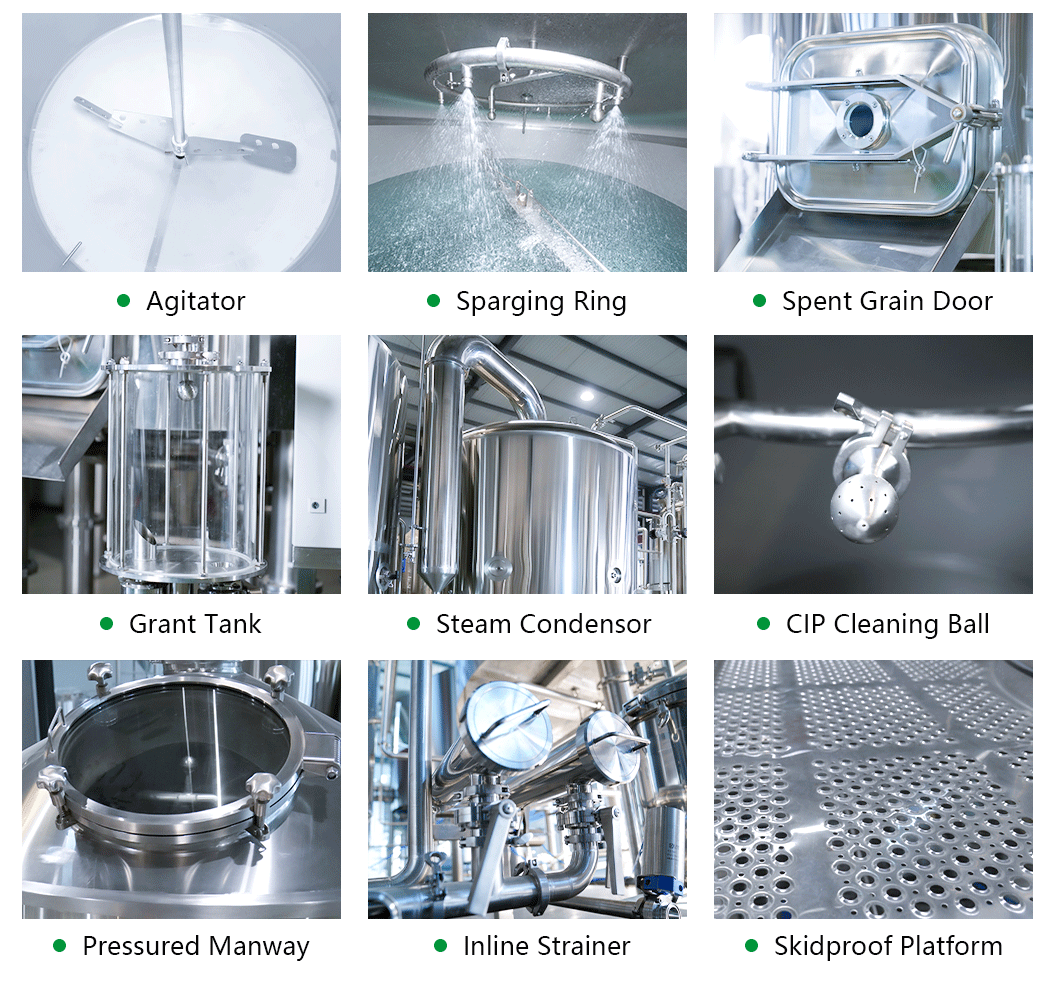

5.Details

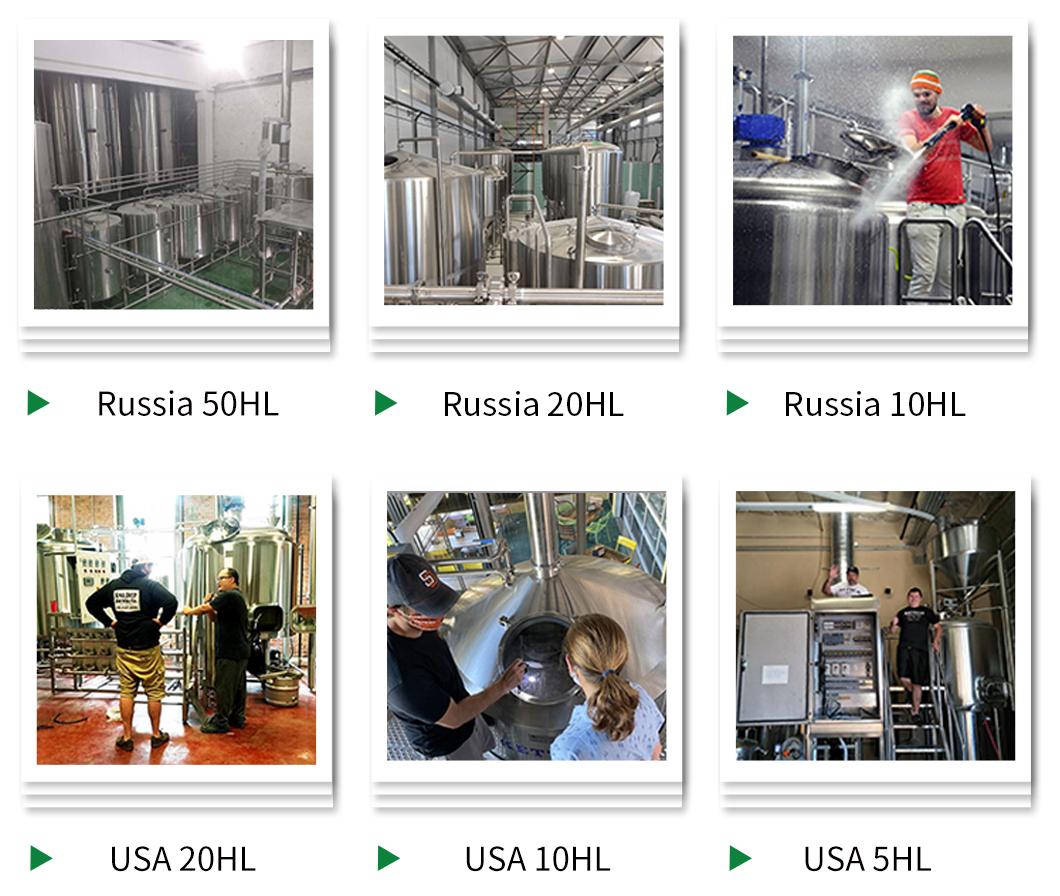

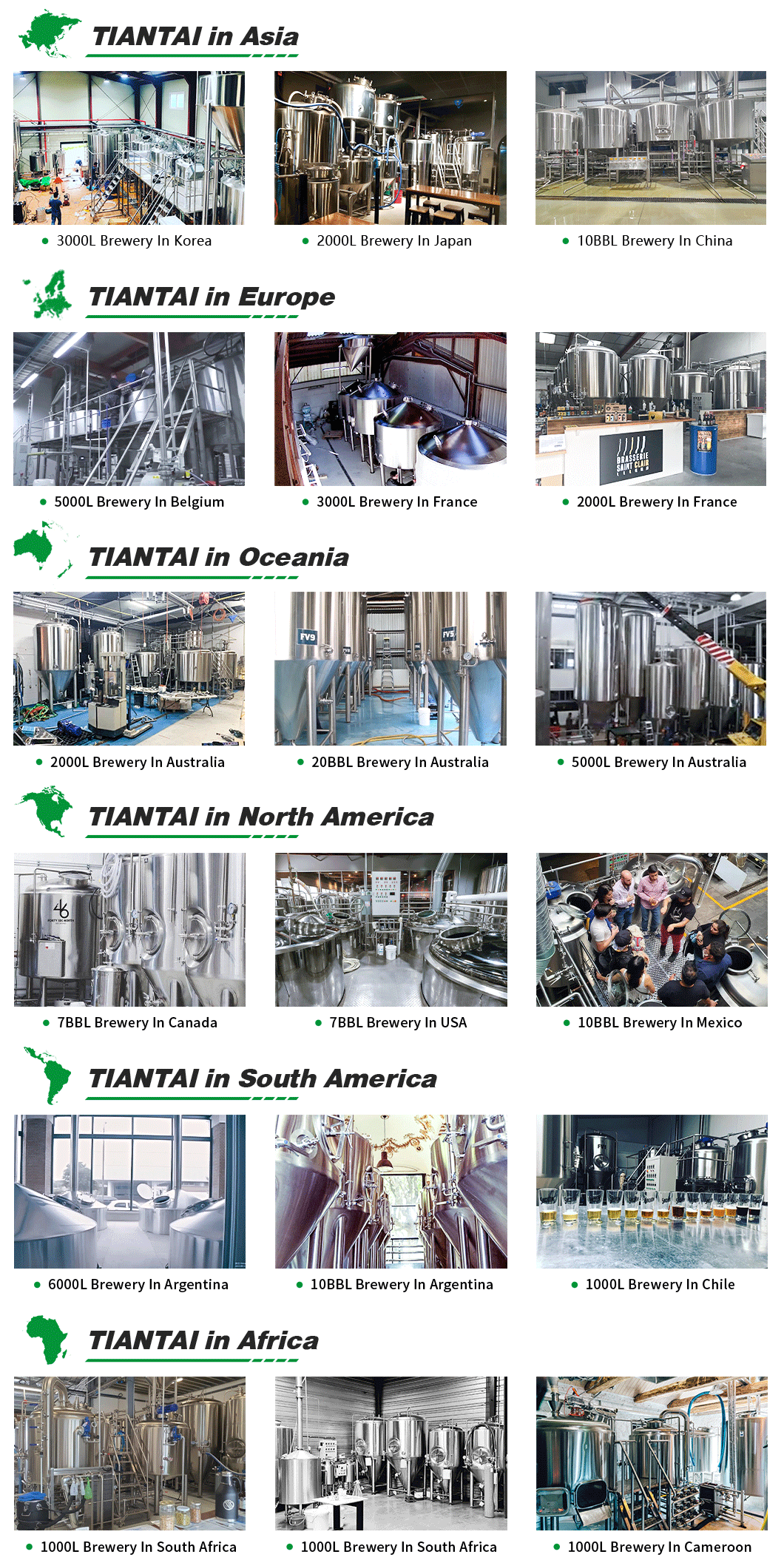

6.Cases worldwide

7. Company Introduction

Tiantai Company, a well-recognized manufacturer of beer and beverage equipment industry based in Jinan city of China, provides complete lines and the turnkey service for breweries and beverage projects worldwide. Since 2001, Tiantai team has witnessed the rapid development of the industry with 23 years of experience. Founded in 2012 and followed by the boom of the craft beer market, Tiantai Company is committed to the research and the development of diverse brewing process, customized equipment, automatic control, and datalized management. Up to now, Tiantai Company has served over 2600 breweries in 106 countries with our equipment and solutions along with gaining good reputations.

Edited By Helen Lee

Sales manager

Email Box: [email protected]

.jpg)

.jpg)

Get In Touch