Key Features of a TIANTAI 10HL 3-Vessel Brewhouse:

1.Brewhouse Configuration:

- Mash Tun: This vessel is used for mixing milled grain (grist) with water and heating it to convert the starches in the grain into fermentable sugars.

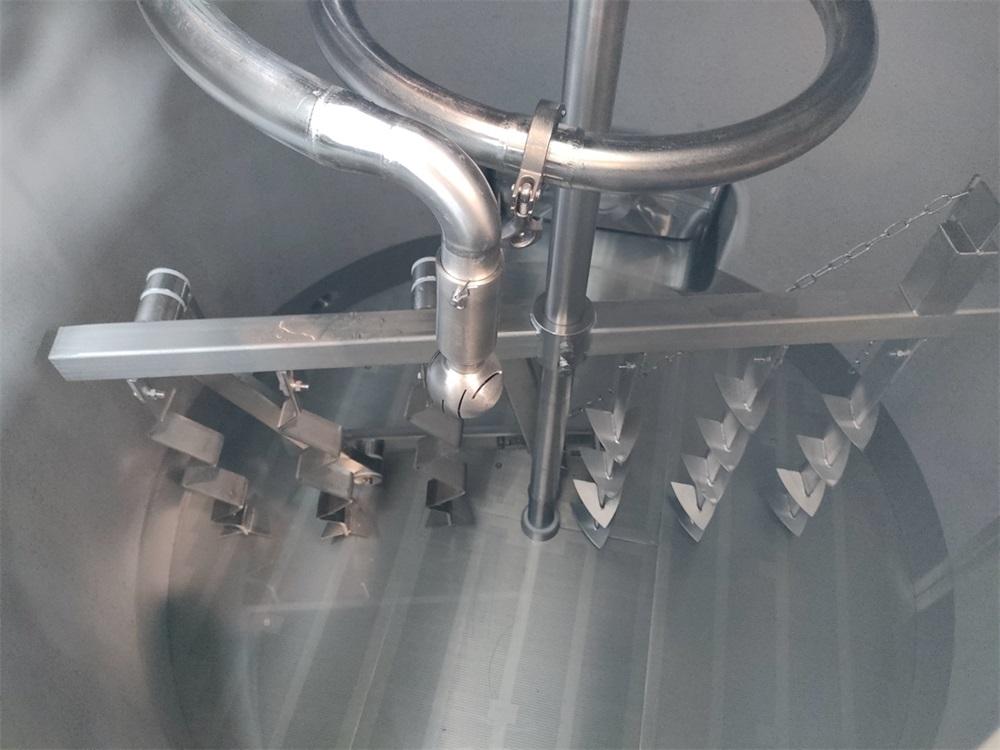

- Lauter Tun: After mashing, the mash is transferred to the lauter tun where the solid and liquid components are separated. The liquid, known as wort, is then collected for boiling.

- Kettle/Whirlpool: The wort is boiled in the kettle, during which hops are added for bitterness, flavor, and aroma. After boiling, the wort is moved to the whirlpool section of the same vessel or a separate vessel for settling and removal of trub (solid particles).

2.Materials and Construction:

- Stainless Steel: The vessels are typically made of high-quality stainless steel (such as SUS304 or SUS316), ensuring durability, ease of cleaning, and resistance to corrosion.

- Insulation: Proper insulation is provided to maintain temperature control during the brewing process.

3.Automation and Control:

- Control System: The system often includes a programmable logic controller (PLC) with a touchscreen interface for precise control over temperatures, timings, and other critical brewing parameters.

- Automation Level: Depending on the specific needs and budget, the level of automation can range from semi-automatic to fully automated systems.

4.Additional Components:

- Heat Exchanger: For quickly cooling the wort before fermentation.

- Pumps and Valves: For efficient transfer of liquids between vessels.

- Piping: Hygienic piping to ensure sanitary conditions throughout the brewing process.

- Cleaning-in-Place (CIP) System: For efficient and thorough cleaning of the equipment.

5.Customization Options:

TIANTAI offers customization options to fit specific brewing needs, including different configurations of vessels, additional features like hop dosing devices, and more.

6.Support and Service:

- Installation and Training: TIANTAI provides installation support and training for brewery staff to ensure proper operation of the brewhouse.

- After-Sales Service: They offer comprehensive after-sales support, including maintenance services and spare parts supply.

7.Benefits of a 10HL 3-Vessel Brewhouse:

- Capacity: Suitable for small to medium-sized batches, allowing for flexibility in production volumes.

- Efficiency: The 3-vessel configuration enables simultaneous brewing processes, such as mashing and lautering, leading to higher productivity.

- Quality Control: Advanced control systems ensure precise management of brewing parameters, resulting in consistent and high-quality beer.

8.Applications:

- Microbreweries: Ideal for startups and established microbreweries looking to expand their production.

- Pilot Plants: Used by larger breweries for experimental batches and recipe development.

- Brewpubs: Perfect for brewpubs that brew beer on-site for serving fresh to customers.

TIANTAI Beer Equipment's 10HL 3-vessel brewhouse is a robust, versatile, and reliable choice for any brewer aiming to produce high-quality craft beer. Our expertise in the field and commitment to quality make them a trusted partner in the brewing industry.

Welcome your proposal, cheers!

Edited By Daisy Cai

[email protected]

.jpg)

.jpg)

.jpg)

Get In Touch