This is a good question from one of our Australia brewery customer. He is deciding the location for grist miller machine. The brewhouse is 800L two vessel brewing system with 600L grist silo on the top of mash/lauter tun. The position of grist miller machine is near to mash tun, so this is why he asked this question.

When designing and installing a flexible auger system in a brewery, there are a few key factors to consider:

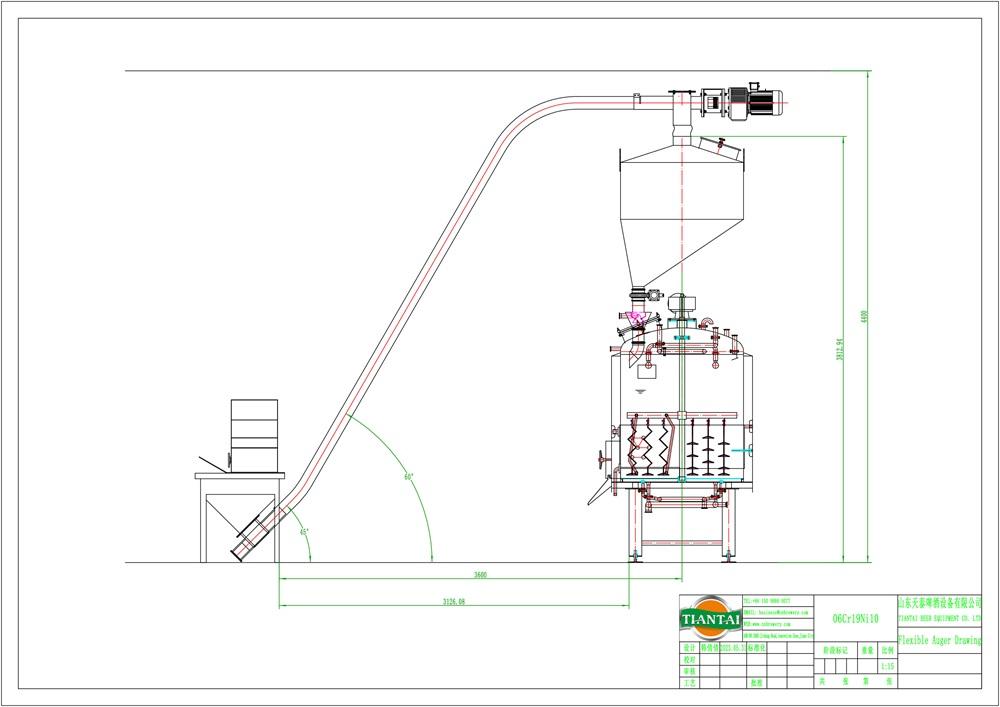

1.Incline Angle: The incline angle of the flexible auger will depend on the specific requirements of the brewery setup and the material being transported. In this case, the suggested incline angle ranges from 45° to 60°.

2.Distance: The distance between the grist miller machine and the mash tun is an important consideration. The shortest distance you mentioned is 3.5 meters. Ensure that the flexible auger is long enough to cover this distance and has the necessary flexibility to accommodate any turns or bends required to reach the destination.

3.Capacity and Flow Rate: It is crucial to ensure that the flexible auger system has the capacity to handle the required flow rate of grist. This will depend on the specific grist miller machine and the brewing system's demands. Consult the manufacturer's specifications for the flexible auger to ensure it can handle the desired flow rate.

4.Safety and Hygiene: When designing the installation, prioritize safety and hygiene. Ensure that the flexible auger system is properly secured, minimizing the risk of accidents or damage. Additionally, consider the materials used in the construction of the auger to ensure they meet food-grade and sanitary standards.

5.Maintenance and Accessibility: Keep in mind that the flexible auger system will require regular maintenance and cleaning. Design the installation in a way that allows for easy access to the auger for inspection, cleaning, and potential repairs.

It's important to note that brewery layouts and equipment configurations can vary, and it is recommended to consult with a professional engineer or equipment supplier experienced in brewery installations. They can provide specific guidance based on the unique requirements of your brewery setup and local regulations.

TIANTAI beer equipment company offers customized brewery and beverage systems. If you or any users have specific requirements or questions regarding microbrewery beer brewing solutions, please definitely reach out. Customized solutions can be invaluable in meeting the unique needs of breweries, it's wonderful to have a company like TIANTAI that can provide turnkey solutions.

Edited By Daisy Cai

[email protected]

.jpg)

Get In Touch