This is to ramp the temperature up to 75°C (167°F) in brewery beer brewing process. This denatures the enzymes and prepares the grain for sparging. the wort is typically recirculated at this temperature for 10 minutes.

The mash out step in brewery stops all of the enzymatic action (preserving your fermentation sugar profile). But as the Tiantai beer equipment brewing units ramp up to near boil as soon as the sparge has started and you sparge with 75°C (167°F) water, the enzymes will be denatured.

So it is good to ramp up to this temp before starting the sparge but this step can be shortened. This is typically done on all types of brewing systems in brewery.

Learn more how Tiaantai beer equipment company to not only produce the best quality brewery equipment for flavor-rich beers, but also help them to optimize the configuration, maximize process uptime and reduce beer loss when they brewing, PLEASE DON’T HESITATE TO CONTACT WITH US!

Hubert

Email: [email protected]

Refequency questions

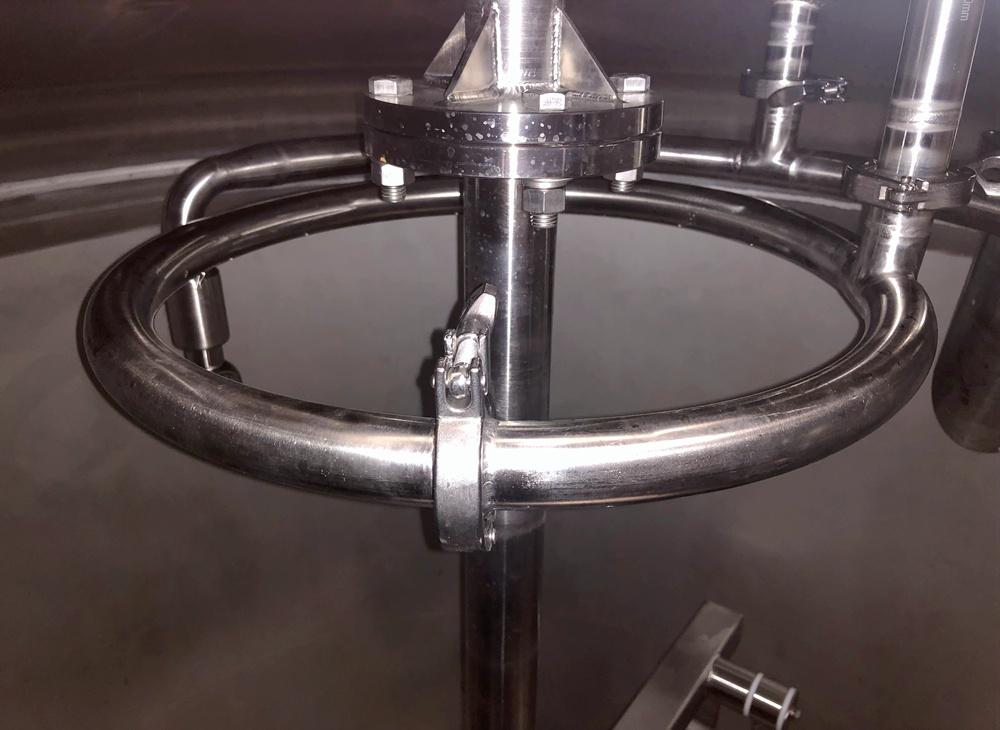

12BBL steam heating mashing beer equipment

1000L stainless steel steam heating beer equipment

Noodledoof Brewing Co. in Australia- 1000L brewery equipment by TIANTAI

.jpg)

Get In Touch